A denitrification catalyst for improving anti-arsenic poisoning performance and its preparation method and application

A denitrification catalyst and arsenic poisoning technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems affecting catalyst activity, selectivity and temperature window , to achieve the effect of improving anti-arsenic poisoning performance, low cost, and improving anti-arsenic poisoning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

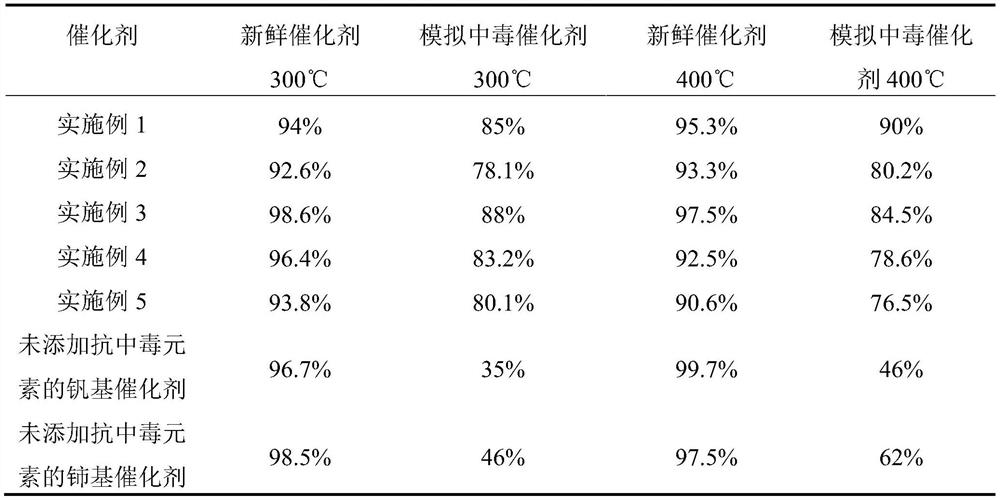

Examples

Embodiment 1

[0021] Example 1 Preparation of VWMgTi catalyst.

[0022] (1) 0.13g of ammonium metavanadate, 0.86g of ammonium metatungstate, 2g of oxalic acid and 1.1g of magnesium nitrate were dissolved in 100mL of deionized water and stirred to obtain a precursor solution;

[0023] (2) Add 9 g of titanium dioxide to the precursor solution in step (1), and stir at room temperature for 120 min to obtain a slurry;

[0024] (3) heating and stirring the slurry at 100° C., gradually evaporating the water in the slurry to obtain a solid;

[0025] (4) The solid substance obtained in step (3) is washed and filtered with deionized water several times, and then dried overnight at 110° C. to obtain a semi-finished product;

[0026] (5) Put the semi-finished product obtained in step (4) into a muffle furnace for roasting. The calcination conditions are as follows: in an air atmosphere, the temperature is raised from room temperature to 500° C. at a rate of 2° C. / min and kept for 4 hours to obtain ...

Embodiment 2

[0027] Example 2 Preparation of VWBaTi catalyst.

[0028] (1) 0.13g of ammonium metavanadate, 0.86g of ammonium metatungstate, 2g of oxalic acid and 0.34g of barium nitrate were dissolved in 100mL of deionized water and stirred to obtain a precursor solution;

[0029] (2) Add 9 g of titanium dioxide to the precursor solution in step (1), and stir at room temperature for 120 min to obtain a slurry;

[0030] (3) heating and stirring the slurry at 100° C., gradually evaporating the moisture in the slurry to obtain a solid;

[0031] (4) The solid material obtained in step (3) is washed and filtered with deionized water several times, and then dried overnight at 110° C. to obtain a semi-finished product;

[0032] (5) Putting the semi-finished product obtained in step (4) into a muffle furnace for roasting to obtain an anti-arsenic poisoning vanadium-tungsten-barium-titanium catalyst.

[0033] The firing conditions are as follows: in air atmosphere, the temperature is raised fr...

Embodiment 3

[0034] Example 3 Preparation of CeWMg catalyst.

[0035] (1) Dissolve 8.68g of cerium nitrate, 7.605g of ammonium tungstate, 2g of oxalic acid and 4.6g of magnesium nitrate in 100mL of deionized aqueous solution and stir to mix;

[0036] (2) Ammonia water with a concentration of 25 wt% was added dropwise to the solution in step (1), controlled at pH=11, and stirred at room temperature for 120 min to fully precipitate;

[0037] (3) Suction filter the precipitate obtained in step (2), and wash it with deionized water several times, and then dry it overnight at 110° C. to obtain a semi-finished product;

[0038] (4) Put the semi-finished product obtained in step (3) into a muffle furnace, and raise it from room temperature to 500°C at a rate of 2°C / min in an air atmosphere and keep it for 4h to prepare an anti-arsenic poisoning cerium-tungsten-magnesium catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com