TPE (thermoplastic elastomer) for syringe piston and preparation method thereof

The technology of a syringe and a piston is applied in the field of TPE for a syringe piston and its preparation, which can solve the problems that the surface is easily broken, the use of liquid or gas in the syringe is affected, and the liquid of the syringe is polluted, and the effect of good puncture is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0048] S1: Premix 5 parts of PP, 20 parts of white oil, 18 parts of SEBS, 0.3 parts of antibacterial agent and 8 parts of reinforcing agent in a high-speed mixer, and control the premixing at 625r / min for 40 minutes to obtain the added mixture;

[0049] S2: adding the added mixture obtained in S1 into a twin-screw extruder with a length-to-diameter ratio of 42:1 for melt extrusion to obtain the added mixture particles;

[0050] S3: Add the mixed particles obtained in S2 and 10 parts of PP, 32 parts of SEBS, 4 parts of hydrogenated petroleum resin, 40 parts of white oil, 6 parts of silicone masterbatch and 1 part of silane coupling agent in the ratio of parts by mass. Mix at 625r / min in the high mixer, and control to mix at 758r / min for 2 hours to obtain molten plastic;

[0051] S4: Put the molten plastic obtained by mixing S3 into a twin-screw extruder with an aspect ratio of 44:1 for melt extrusion to obtain TPE plastic particles for syringe pistons.

[0052]The antibacteria...

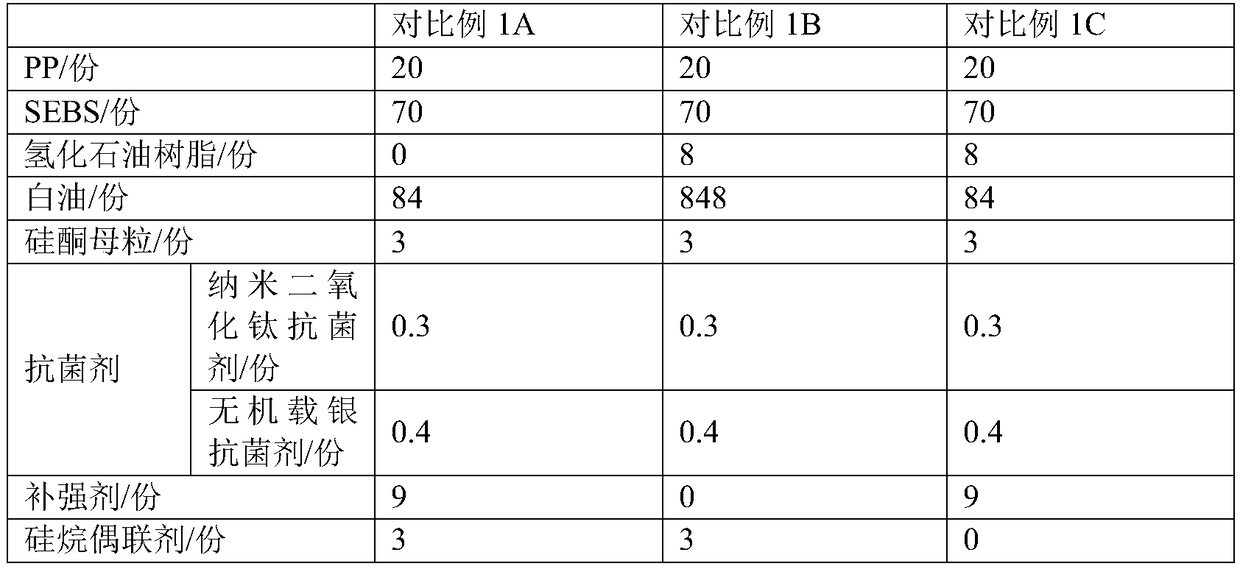

Embodiment 1B-1F

[0054] On the basis of Example 1A, the mass parts of the amount of raw materials were changed to obtain multiple sets of TPE. The raw material consumption is as follows.

[0055]

[0056]

[0057] The above-mentioned nano-titanium dioxide antibacterial agent selects the powder product of AMT-600 from Japan Titanium Division (TAYCA).

Embodiment 2A-2C

[0073] Improvement was made on the basis of Example 1A, heating was performed during premixing in S1, wherein the temperature of Example 2A was controlled at 60°C, the temperature of Example 2B was controlled at 65°C, and the temperature of Example 2C was controlled at 68°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com