Building energy-saving material and preparation process thereof

A technology of building energy-saving and shape-setting phase change materials, applied in the field of materials, can solve the problems of poor mechanical properties and fire resistance, heavy bulk density of inorganic thermal insulation materials, high VOC content, etc., to achieve fire prevention and durability, good thermal insulation effect, and sound absorption effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

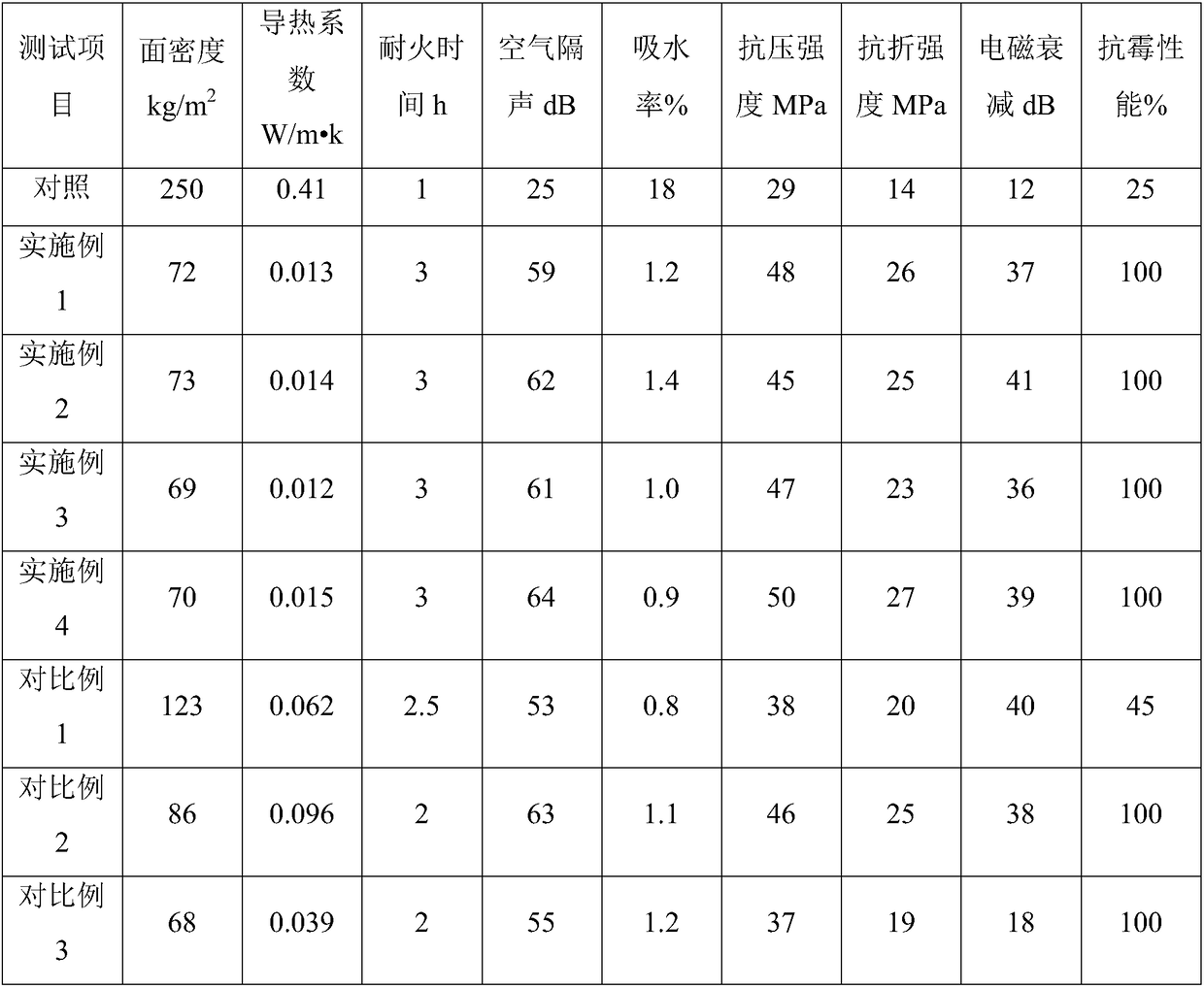

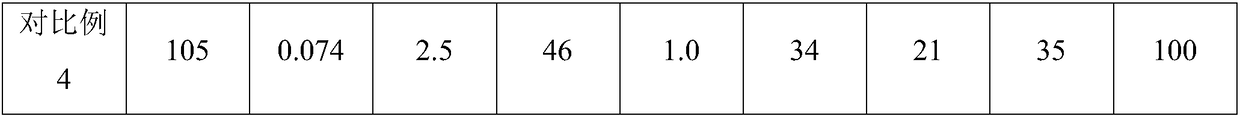

Examples

Embodiment 1

[0037] A building energy-saving material, made of the following components in parts by weight: 25 parts of fly ash, 0.1 part of sodium hydroxide, 12 parts of water glass, 0.2 parts of calcium stearate, dodecylbenzenesulfonic acid 0.4 parts of sodium, 13 parts of hemp fiber, 6 parts of shape-setting phase change material, 5 parts of chopped carbon fiber, 3 parts of sepiolite wool, 10 parts of modified cellulose airgel, 6 parts of starch-based porous carbon material, talcum powder 1 serving.

[0038] Further, the shape-setting phase-change material is a phase-change material fatty acid ternary eutectic, that is, LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is loaded in a mass ratio of 6:2:2 Expanded perlite and modified diatomaceous earth are on the base material with a mass ratio of 1:1; the mass content of LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) in the shape-setting phase change material is equal to 25 %.

[0039] Further, the length of the chopped carbon ...

Embodiment 2

[0046] A building energy-saving material, made of the following components in parts by weight: 28 parts of fly ash, 0.3 parts of sodium hydroxide, 16 parts of water glass, 0.3 parts of calcium stearate, dodecylbenzenesulfonic acid 0.5 parts of sodium, 15 parts of hemp fiber, 8 parts of shape-setting phase change material, 11 parts of chopped carbon fiber, 5 parts of sepiolite wool, 17 parts of modified cellulose airgel, 9 parts of starch-based porous carbon material, talcum powder 2 servings.

[0047] Further, the shape-setting phase-change material is a phase-change material fatty acid ternary eutectic, that is, LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is loaded in a mass ratio of 6:2:2 Expanded perlite and modified diatomaceous earth are on the base material with a mass ratio of 1.2:1; the mass content of LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) in the shape-setting phase change material is equal to 35 %.

[0048] Further, the length of the chopped ca...

Embodiment 3

[0055] A building energy-saving material, made of the following components in parts by weight: 35 parts of fly ash, 0.4 parts of sodium hydroxide, 20 parts of water glass, 0.35 parts of calcium stearate, dodecylbenzenesulfonic acid 0.7 parts of sodium, 17 parts of hemp fiber, 12 parts of shape-setting phase change material, 13 parts of chopped carbon fiber, 6 parts of sepiolite wool, 20 parts of modified cellulose airgel, 15 parts of starch-based porous carbon material, talcum powder 2.5 servings.

[0056] Further, the shape-setting phase-change material is a phase-change material fatty acid ternary eutectic, that is, LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is loaded in a mass ratio of 6:2:2 Expanded perlite and modified diatomaceous earth are on the base material with a mass ratio of 1.4:1; the mass content of LA (lauric acid)-PA (palmitic acid)-SA (fatty acid) is equal to 40% in the described shape-setting phase change material %.

[0057] Further, the length o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com