Rod making machine and rod making machine system

A technology of rod making machine and turntable mechanism, which is applied in the direction of presses, manufacturing tools, material forming presses, etc., can solve the problems of easy loosening, difficult ignition, difficult production and application, etc., and achieve high forming strength and sufficient combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

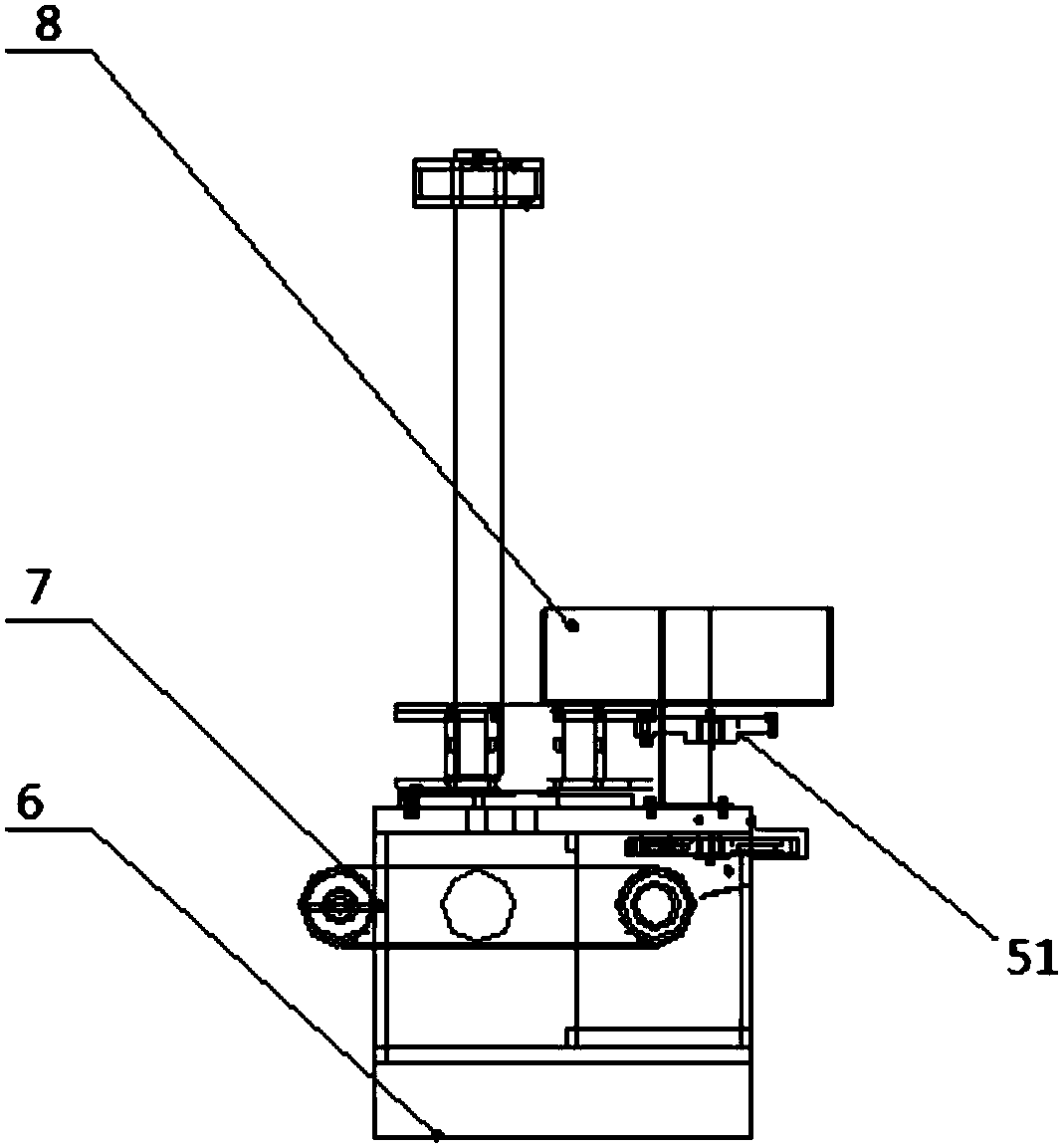

[0043] see Figure 1 to Figure 6 As shown, this embodiment provides a rod making machine, which includes a base 6 , a driving mechanism 1 , a stamping mechanism 3 , a turntable mechanism 4 , a material feeding mechanism 8 and a material discharging mechanism 7 .

[0044] The drive mechanism 1 includes a reducer 13 connected to the motor 12 and the output shaft of the motor 12, the output shaft of the reducer 13 is the power shaft 11, and the first power output assembly 2 is arranged on the power shaft 11 And the second power output assembly 5.

[0045] The stamping mechanism 3 includes a horizontal support bar 31, a stamping assembly 32 and a stamping discharge assembly 33, the stamping assembly 32 and the stamping discharge assembly 33 are respectively arranged below the horizontal support bar 31, and the first power output The component 2 drives the horizontal support rod 31 , the punching component 32 and the punching and discharging component 33 to move up and down repeated...

Embodiment 2

[0087] This embodiment provides a rod making machine system, including the rod making machine as described in Embodiment 1 and the electrical components for controlling the driving mechanism 1 of the rod making machine.

[0088] The electrical assembly is connected with the motor 12 of the drive mechanism 1 of the rod making machine, which can control the opening, closing and emergency braking of the motor of the rod making machine.

[0089] The electrical components of the rod making machine system in this embodiment can use existing electrical control components. The structure of the rod making machine has been described in detail in Embodiment 1, and will not be repeated here.

[0090] The rod making machine system in this embodiment has the same beneficial effects as the rod making machine in Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com