Roller roller-sleeve extrusion and vibration casting production method

A roll sleeve and casting production technology, applied in the field of roll production, can solve the problems of low service life of the roll, and achieve the effects of improving the density of the roll, improving the shrinkage and porosity, and improving the service life of the roll.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

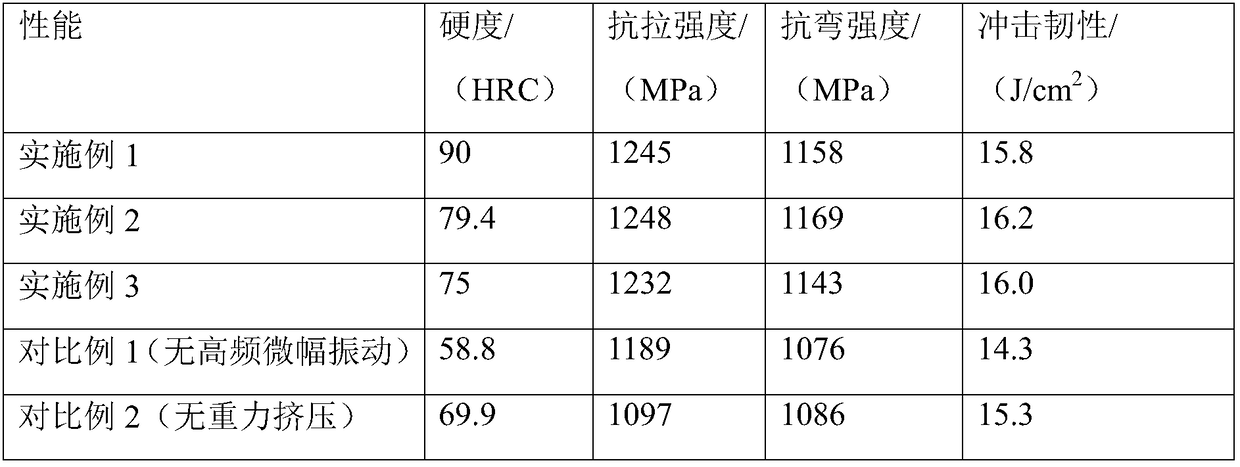

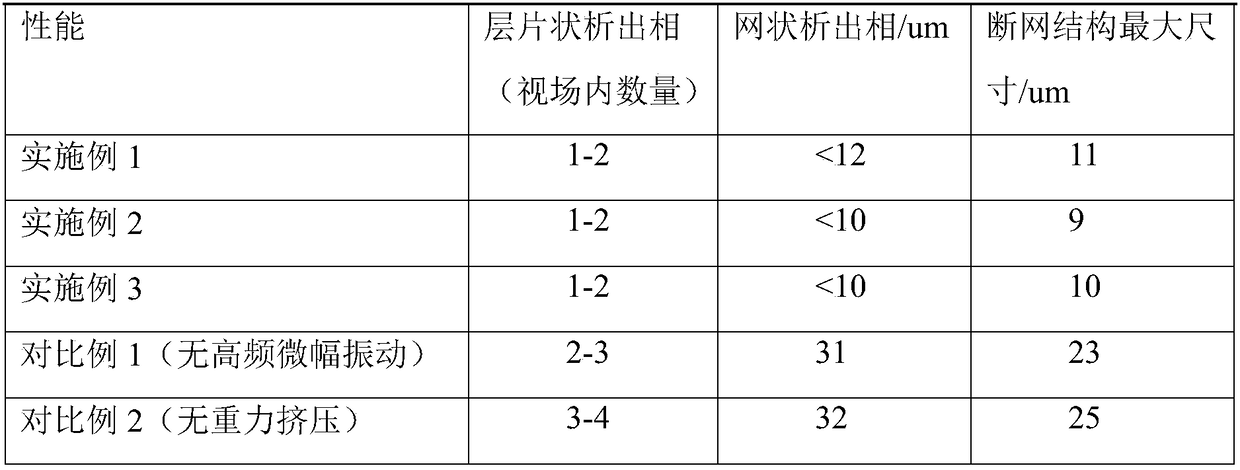

Examples

Embodiment 1

[0039] This embodiment provides a production method for extrusion vibration casting of roll sleeves, comprising the following steps:

[0040] S1: Fill the cavity of the vertical roll sleeve mold with molten metal and seal the cavity;

[0041] S2: Vibrate the roll sleeve mold at the same time or before injecting the molten metal, and vibrate with the molten metal in the mold, the vibration frequency is 200Hz, and the amplitude is 20μm;

[0042] S3: Apply vertical pressure to the molten metal in the solidification process of the roll sleeve mold, and the pressure generated when the vertical pressure is applied to the slab is 10 MPa;

[0043] S4: After the molten metal is completely solidified, keep the vibration and pressure for 10 minutes before opening the mold.

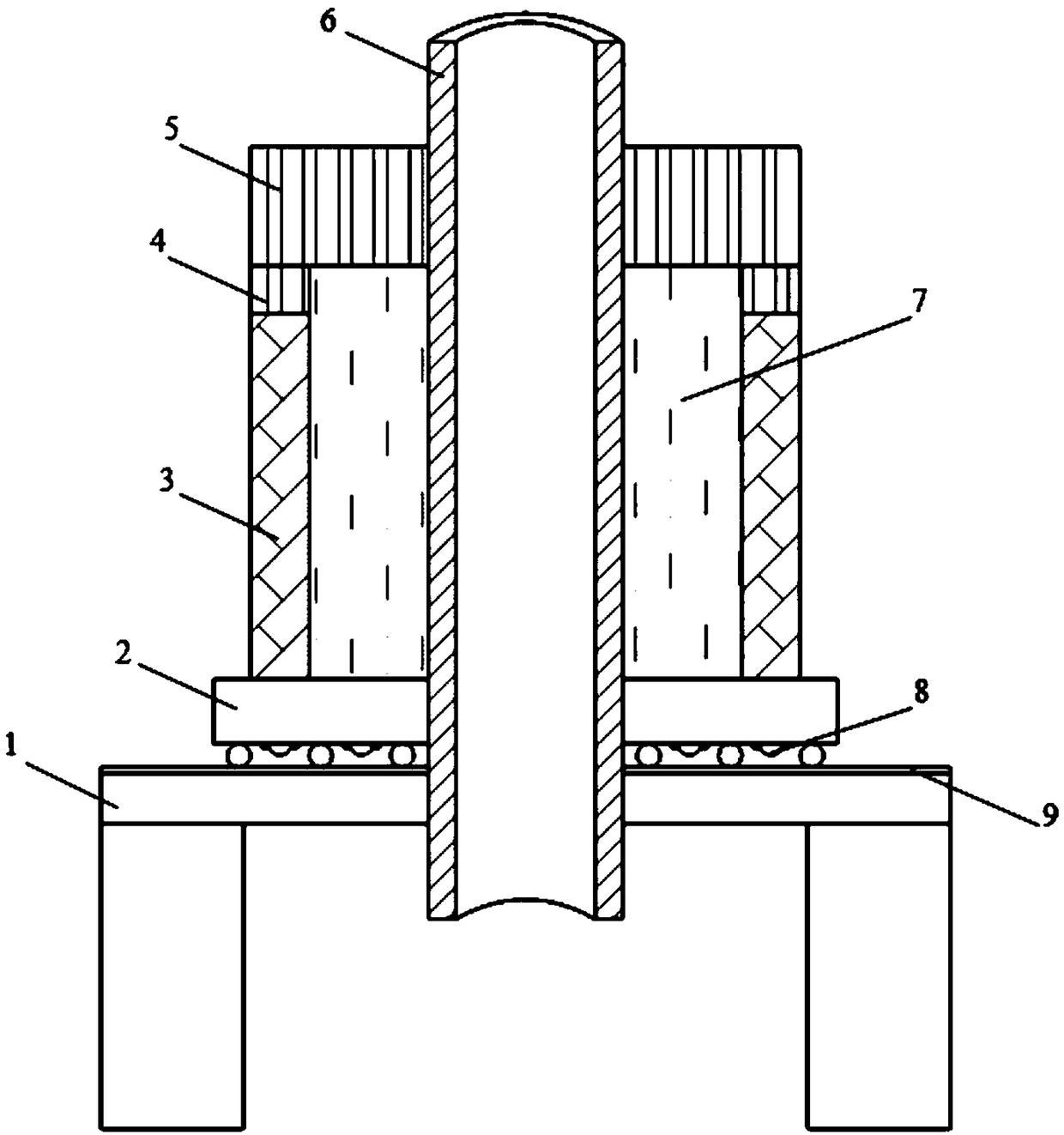

[0044] A specific way of the roller sleeve mold is: comprising a bottom mold 2, a side mold 3 and a fixed cylindrical roll mandrel 6, the bottom of the bottom mold 2 is provided with a The vibration motor 8.

[00...

Embodiment 2

[0049] This embodiment provides a production method for extrusion vibration casting of roll sleeves, comprising the following steps:

[0050] S1: Fill the cavity of the vertical roll sleeve mold with molten metal and seal the cavity;

[0051] S2: Vibrate the roll sleeve mold at the same time or before injecting the molten metal, and vibrate with the molten metal in the mold, the vibration frequency is 250Hz, and the amplitude is 24μm;

[0052] S3: Apply vertical pressure to the molten metal in the solidification process in the roll sleeve mold, and the pressure generated when the vertical pressure is applied to the casting is 25MPa;

[0053] S4: After the molten metal is completely solidified, keep the vibration and pressure for 12 minutes before opening the mold.

[0054] A specific way of the roller sleeve mold is: comprising a bottom mold 2, a side mold 3 and a fixed cylindrical roll mandrel 6, the bottom of the bottom mold 2 is provided with a The vibration motor 8.

[...

Embodiment 3

[0059] This embodiment provides a production method for extrusion vibration casting of roll sleeves, comprising the following steps:

[0060] S1: Fill the cavity of the vertical roll sleeve mold with molten metal and seal the cavity;

[0061] S2: Make the roll sleeve mold vibrate at the same time or before injecting the molten metal, and vibrate with the molten metal in the mold, the vibration frequency is 300Hz, and the amplitude is 30μm;

[0062] S3: Apply vertical pressure to the molten metal in the solidification process of the roller sleeve mold, and the pressure generated when the vertical pressure is applied to the casting is 50MPa;

[0063] S4: After the molten metal is completely solidified, keep the vibration and pressure for 15 minutes before opening the mold.

[0064] A specific way of the roller sleeve mold is: comprising a bottom mold 2, a side mold 3 and a fixed cylindrical roll mandrel 6, the bottom of the bottom mold 2 is provided with a The vibration motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com