Preparation method and application of composition of 2,4-dichlorophenoxyacetic acid and 2,4-dichlorophenoxyacetate

A technology of dichlorophenoxyacetate and dichlorophenoxyacetic acid, applied in the field of phenoxycarboxylate synthesis, can solve problems such as incomplete reaction, instability, poor product quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

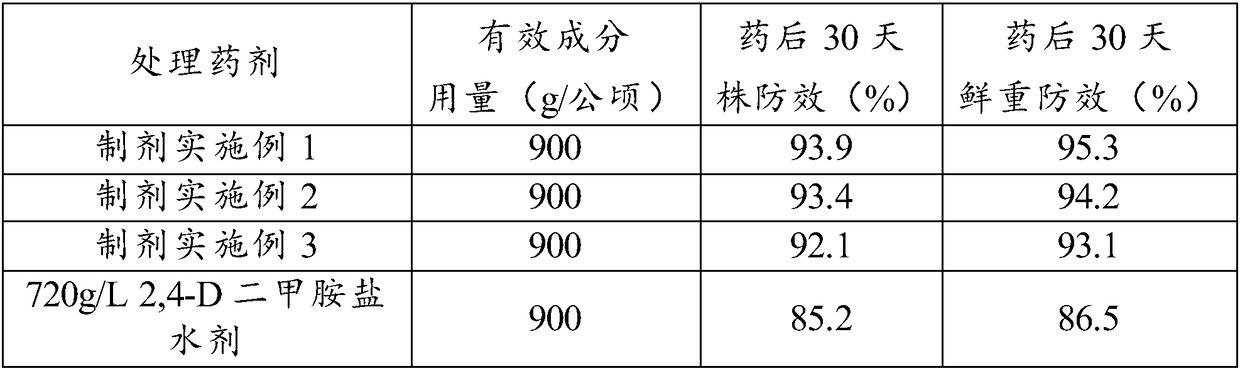

[0094] Combine 123g (1mol) of ethyl chloroacetate and 186g (1mol) of 2,4-dichlorophenate sodium, heat and stir for 3 hours, filter off the sodium chloride solid generated by the reaction, and ethanol is stripped from the filtrate to obtain 2,4-dichlorobenzene Ethyl oxyacetate, add 0.5g concentrated sulfuric acid, keep stirring at 80°C for 2h, crystallize at 10°C for 1h, filter, and dry the filter cake to obtain 2,4-dichlorophenoxyacetic acid and 2,4-dichlorophenoxyacetic acid Ester composition 230g.

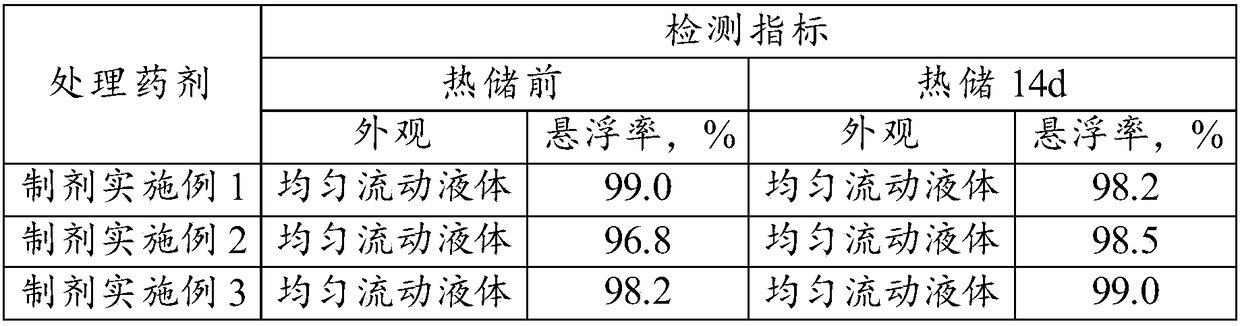

[0095] The composition prepared in Example 1 of the present invention was prepared into a suspoemulsion.

[0096]The preparation method specifically includes the following steps: combining 2,4-dichlorophenoxyacetic acid and 2,4-dichlorophenoxyacetic ester, an emulsifier, a wetting and dispersing agent, a defoamer, a thickening stabilizer, The antifreeze agent and water are uniformly sheared and mixed at high speed, and ball milled in a ball mill for 2 to 3 hours, so that the par...

Embodiment 2

[0099] Combine 151g (1mol) butyl chloroacetate and 186g (1mol) of 2,4-dichlorophenate sodium, heat and stir for 3h, filter off the sodium chloride solid generated by the reaction, and remove butanol from the filtrate to obtain 2,4-dichlorophenate Butyl phenoxyacetate, add 0.3g p-toluenesulfonic acid, keep stirring at 120°C for 2h, crystallize at 10°C for 1h, filter, and dry the filter cake to obtain 2,4-dichlorophenoxyacetic acid and 2,4-dichlorobenzene Oxyacetate composition 228g.

[0100] The composition prepared in Example 2 of the present invention was prepared into a suspoemulsion.

[0101] The formula is: 2,4-dichlorophenoxyacetic acid and 2,4-dichlorophenoxyacetic ester composition 42%, calcium dodecylbenzenesulfonate 1%, phenylethylphenol polyoxyethylene polyoxypropylene Ether 2%, naphthalenesulfonic acid formaldehyde condensate sodium salt 3%, polycarboxylate sodium salt 1%, calcium lignosulfonate 1%, ethylene glycol 5%, silicone compounds 0.5%, magnesium aluminum si...

Embodiment 3

[0103] Combine 210g (1mol) of butyl bromoacetate and 186g (1mol) of 2,4-dichlorophenate sodium, heat and stir for 3 hours, filter off the solid sodium bromide generated by the reaction, and remove butanol from the filtrate to obtain 2,4-dichlorophenate Butyl phenoxyacetate, add 0.3g acetic acid, keep stirring at 120°C for 2h, crystallize at 10°C for 1h, filter, and dry the filter cake to obtain 2,4-dichlorophenoxyacetic acid and 2,4-dichlorophenoxyacetic acid Ester composition 236g.

[0104] The composition prepared in Example 3 of the present invention was used for suspoemulsion.

[0105] The formula is: 2,4-dichlorophenoxyacetic acid and 2,4-dichlorophenoxyacetic ester composition 26%, phenethylphenol polyoxyethylene ether 1%, castor oil polyoxyethylene ether 2%, naphthalene Sulfonic acid formaldehyde condensate sodium salt 1%, polycarboxylate sodium salt 3%, calcium lignosulfonate 1%, ethylene glycol 5%, silicone compounds 0.3%, magnesium aluminum silicate 0.14%, xanthan g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com