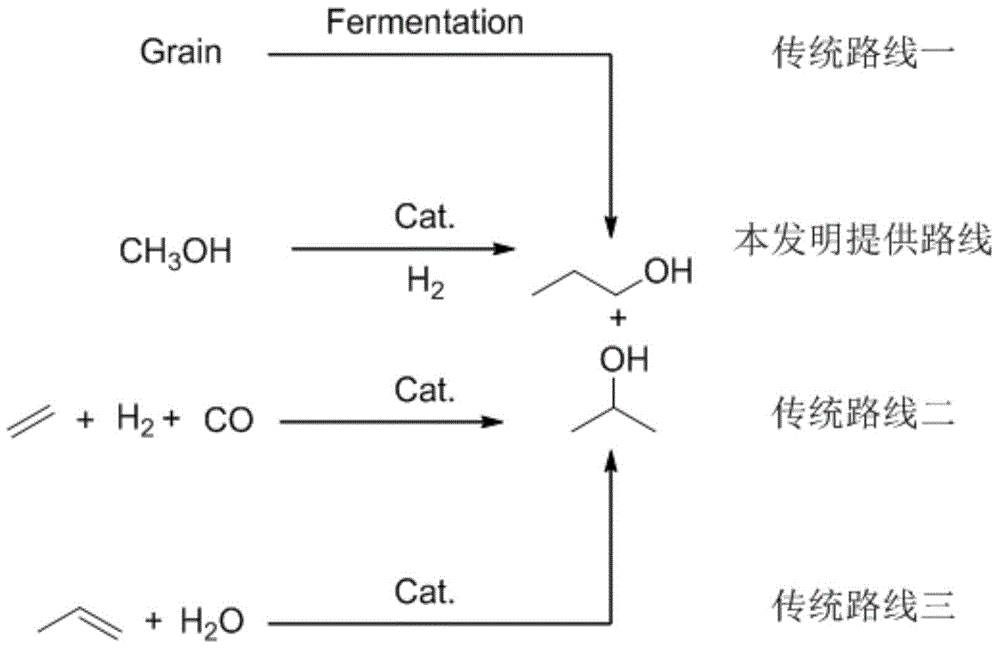

Method for preparing propanol through catalytic conversion of methanol

A technology for catalyzing methanol and catalytic conversion, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of production shutdown, production reduction, poor compatibility, etc., to reduce dependence on petroleum, important application prospects, Efficient effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Take the impregnation method to prepare Cu-Cr / ZSM-5 catalyst as an example to describe the steps of impregnation method to prepare supported composite metal oxide catalyst: according to Cu:Cr molar ratio=2:1, weigh 2.44g nitric acid respectively Copper [Cu(NO 3 ) 2 ·3H 2 O] and 2.02g (Cu:Cr molar ratio = 1:1, 4.04g) chromium nitrate [Cr(NO 3 ) 3 9H 2 O] as a raw material, dissolved in 40ml deionized water, and prepared into an active component salt solution (wherein the loading of the active component is 0.1-20%, and the two-component Cu:Cr molar ratio is 0.1-10:1, as in this 2:1 and 1:1 respectively), the carrier ZSM-5 was immersed in the solution for 24 hours; then the solution was evaporated to dryness, and then calcined at 500°C for 4 hours to obtain the CuCr / ZSM-5 catalyst.

Embodiment 2

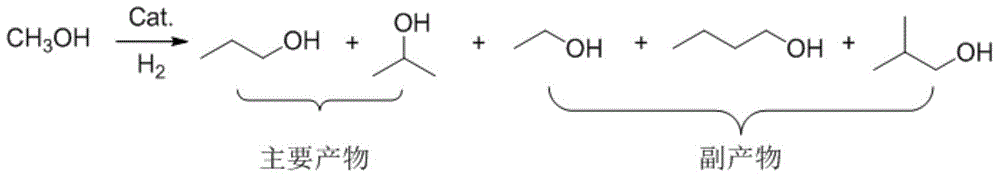

[0019] Example 2: 10ml of Cu-Cr / ZSM-5 (where Cu:Cr molar ratio = 2:1, active metal component loading is 10%) catalyst particles synthesized in the laboratory were loaded into a fixed-bed reactor, replaced by nitrogen The air in the system was followed by hydrogen gas, and the reaction temperature was raised to 350°C. Use a pump to feed methanol into the reactor to contact with the catalyst for reaction, the feed space velocity of methanol is 2h -1 , the reaction pressure is 0.5MPa. After the reaction was stable, the sample was analyzed by Agilent7890A-5973C GC-MS coupled instrument and HP-5 chromatographic column for product composition (such as figure 2 shown), mainly propanol (including n-propanol and isopropanol), and a small amount of ethanol, n-butanol and isobutanol were also detected, and the reaction products were quantitatively analyzed by Agilent7890A. Combined with the results of gas chromatography analysis, the selectivity of propanol in the product was calculat...

Embodiment 3

[0020] Example 3: 10ml of Cu-Cr / ZSM-23 (where Cu:Cr molar ratio = 1:1, active metal component loading is 10%) catalyst particles synthesized in the laboratory were loaded into a fixed-bed reactor and replaced with nitrogen The air in the system was followed by hydrogen gas, and the reaction temperature was raised to 380°C. Use a pump to feed methanol into the reactor to contact with the catalyst for reaction, the feed space velocity of methanol is 2.5h -1 , the reaction pressure is 2.0MPa. After the reaction was stable, the product was analyzed according to the method in Example 2, and the selectivity to propanol was 75.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com