CS-Salen-Mn-type composite catalyst based on natural polymer chitosan and preparation method

A composite catalyst and natural polymer technology, which is applied in the field of CS-Salen-Mn composite catalyst and its preparation, can solve the problems of long experimental period, catalyst deactivation, complicated operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

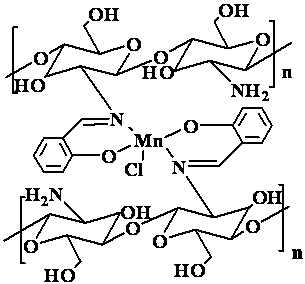

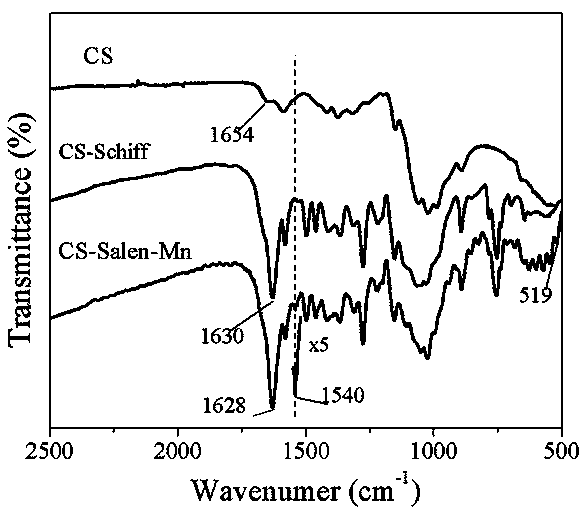

Image

Examples

Embodiment Construction

[0026] (1) Dissolve the weighed 0.5 g CS in 25 mL of dilute acetic acid with a volume fraction of 1%, put it in a magnetic stirrer, stir until the chitosan dissolves, add 100 mL of deionized water and stir until it reaches a colloidal state;

[0027] (2) Dissolve 0.565 mL of salicylaldehyde in 20 mL of absolute ethanol, add this solution dropwise to the colloidal solution described in step 1, the solution turns yellow, and adjust the pH to neutral. At this time, the colloidal solution became turbid, and the stirring was continued for 12 h;

[0028] (3) After 12 hours, filter the turbid liquid in the process of step 2, and alternately wash several times with absolute ethanol and deionized water to obtain a light yellow solid;

[0029] (4) Dissolve the solid substance obtained in step 3 in 150 mL of absolute ethanol, stir the solution in a heated magnetic stirrer, and heat the temperature to 80 °C, and weigh 1.46 g of Mn(OAC) 2 4H 2 O was added to the solution, and the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com