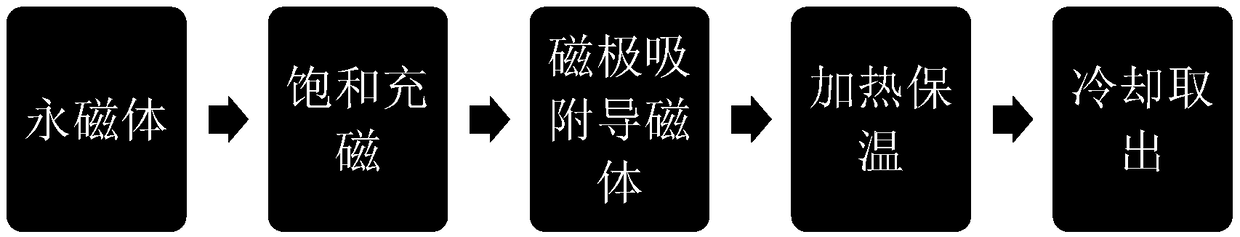

A kind of high temperature resistant permanent magnet pre-stabilization treatment method

A processing method and permanent magnet technology, applied in the direction of magnets, permanent magnets, magnetic objects, etc., to achieve high magnetic performance, eliminate magnetic flux loss, and maintain the effect of magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

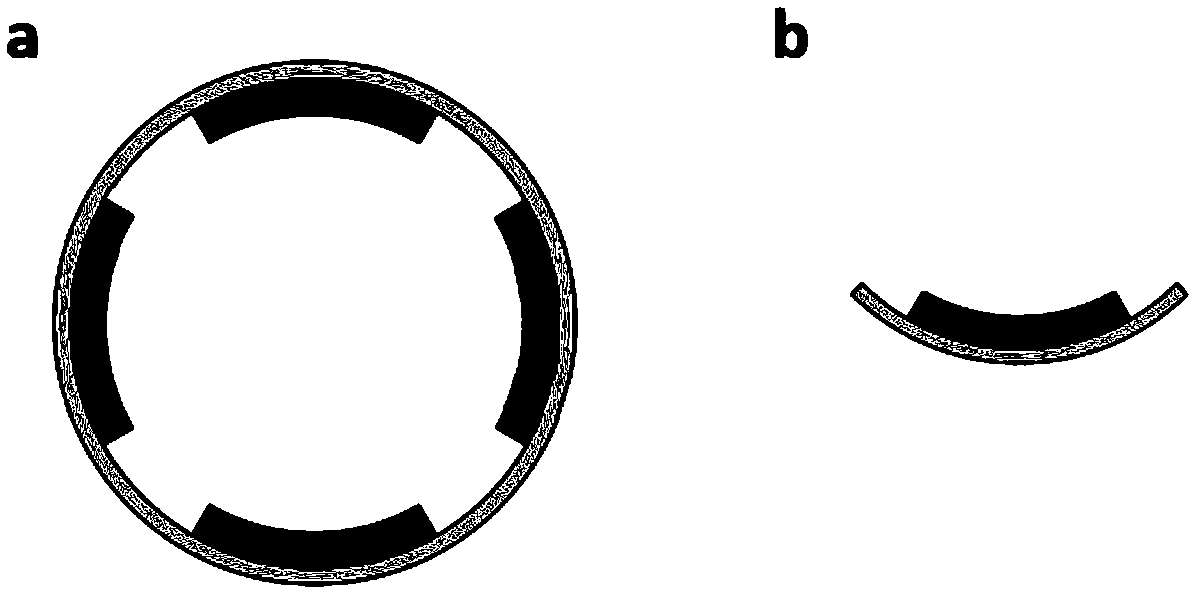

[0027] In this embodiment, the permanent magnet is a high temperature resistant NdFeB permanent magnet material that can reach 150 ° C, such as figure 2 As shown in a in the figure, when the permanent magnet is used in the device, it is cut into four arc-shaped pieces (outer diameter 100mm, inner diameter 87mm, angle 45°, thickness 8mm) from the blank, and the magnetization direction of the permanent magnet is radial. After 5T magnetic field magnetization, pre-stabilization treatment, built in the inner wall of the ring magnet, in the form of a semi-closed magnetic circuit. The method of pre-stabilizing the permanent magnet is as follows: figure 2 As shown in b in the figure, a single piece of single magnetic pole is adsorbed on an electrical pure iron arc, placed in a vacuum heating furnace and heated to 180°C for 2 hours, and the vacuum degree is maintained at 10 -3 Pa, and then take it out with the furnace cooling. Use a fluxmeter (Model 480, Lake Shore) to measure the ...

Embodiment 2

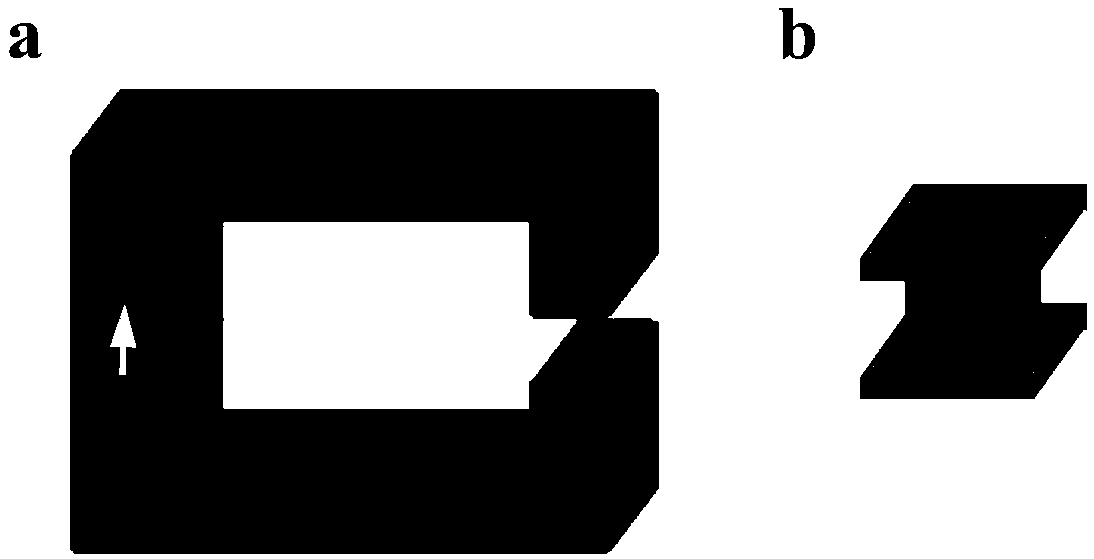

[0029] In this embodiment, the permanent magnet is a high temperature resistant samarium cobalt permanent magnet material that can reach 300 ° C, such as image 3 As shown in a, when the permanent magnet is used in the device, it is cut into the required shape from the blank, and the size is 10×12×9mm. The magnetization direction of the permanent magnet is along the length direction of 9mm as shown in the figure, and the magnetic field is 10T After magnetization and pre-stabilization treatment, the two magnetic poles are adsorbed by electric pure iron magnetizers to form a closed magnetic circuit. The method of pre-stabilizing the permanent magnet is as follows: image 3 As shown in b, the two magnetic poles of a single piece are adsorbed by electrical pure iron plates, placed in a vacuum heating furnace and heated to 350°C for 2 hours, and the vacuum degree is maintained at 10 -3Pa, and then take it out with the furnace cooling. Use a fluxmeter (Model 480, Lake Shore) to me...

Embodiment 3

[0031] In this embodiment, the permanent magnet is a high temperature resistant samarium cobalt permanent magnet material that can reach 550°C, such as Figure 4 As shown in a, when the permanent magnet is used in the device, it is cut into 12 sector-shaped permanent magnets from the permanent magnet blank, the magnetization direction is radial, and the 10T magnetic field is magnetized. After pre-stabilization treatment, it is assembled into a ring (outer diameter 80mm, inner diameter 72mm, thickness 5mm), both inside and outside have 1J22 magnetizer rings in the form of a closed magnetic circuit. The method of pre-stabilizing the permanent magnet is as follows: Figure 4 As shown in middle b, according to the size of the uniform temperature zone of the heating furnace, multiple fan-shaped permanent magnets are adsorbed together end to end according to the magnetization direction, and the outermost permanent magnets at both ends are adsorbed on the 1J22 magnetic conduction arc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com