High temperature superconducting flux pump and method for controlling current waveform of iron core winding

A technology of high-temperature superconductivity and current waveform, which is applied in superconducting magnets/coils, usage of superconductor elements, transformer/inductor cores, etc., can solve problems such as inconvenient use and complex structure, and achieve convenient use, small size, The effect of increasing the charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

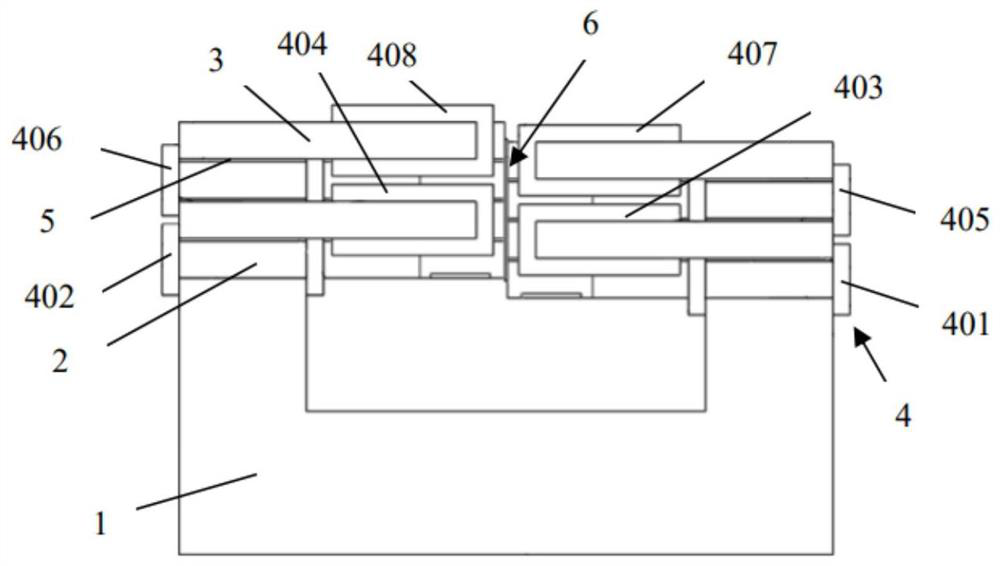

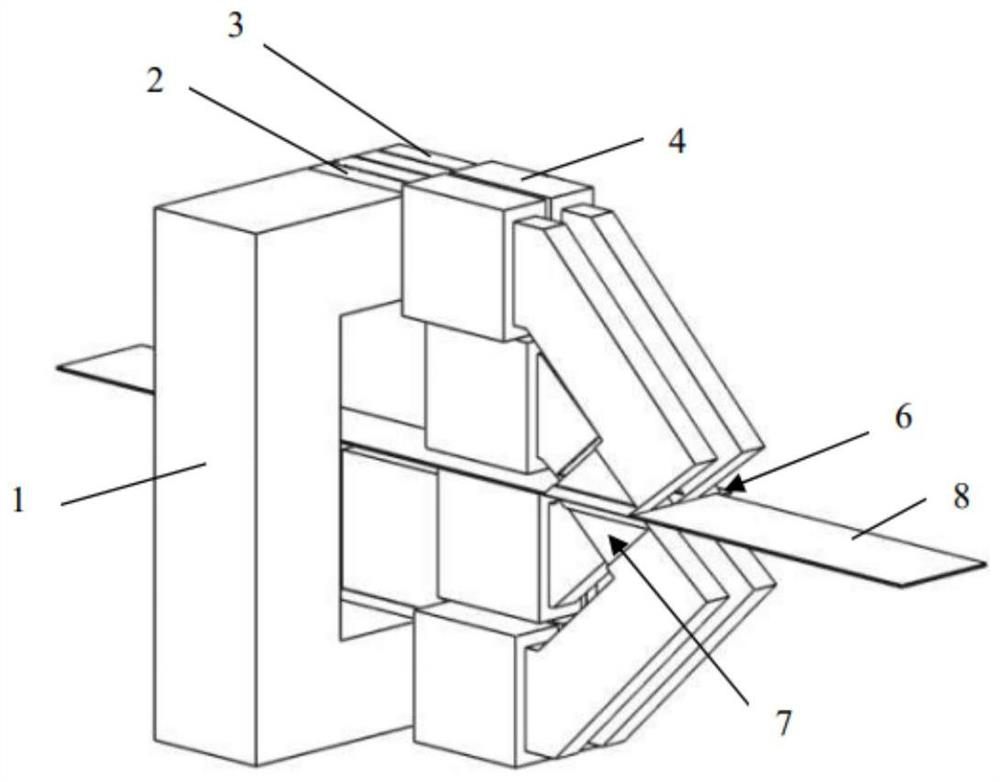

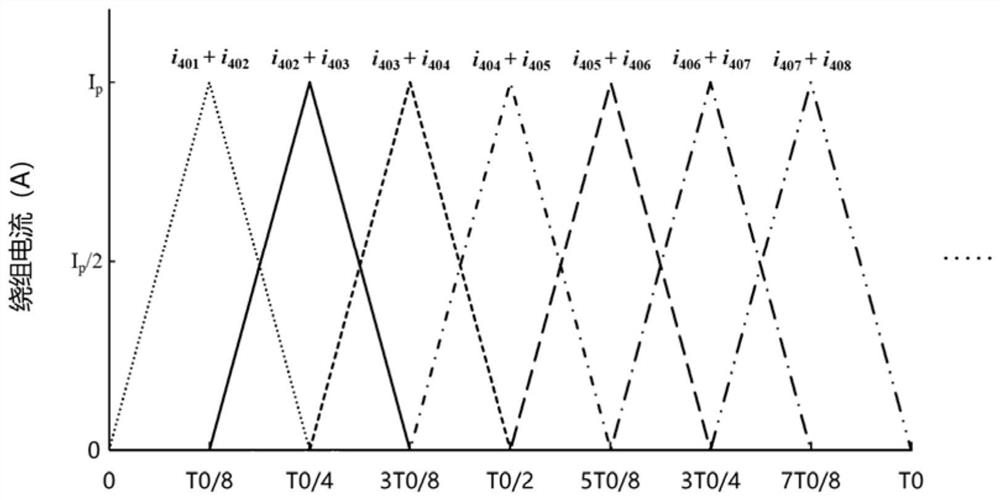

[0055] like Figure 4 As shown, according to a high-temperature superconducting magnetic flux pump provided by the present invention, the supporting iron core 1 is a C-shaped iron core, and two first iron cores 2 are fixedly installed at both ends of the supporting iron core 1, and the two first iron cores 2 are respectively fixed. A side of the iron core 2 facing away from the supporting iron core 1 is sequentially installed and fixedly installed with two second iron cores 3 and a first iron core 2 , any one of the first iron core 2 and the second iron core 3, the second iron core 2 Both the iron core 3 and the second iron core 3 are connected by silicon steel sheets 5 . Any group of first iron cores 2 at both ends of the supporting iron core 1 are arranged oppositely, and any group of second iron cores 3 at both ends of the supporting iron core 1 are also arranged oppositely, and any group is an oppositely arranged first iron core. The cores 2 are all arranged in a staggere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com