Reactor

A reactor and iron yoke technology, applied in circuits, transformer/inductor cores, electrical components, etc., can solve the problems of space compression of the winding winding of the reactor, the inability to provide the reactor structure, and the inability to wind the coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As mentioned in the background art, the prior art cannot provide a reactor structure that can take into account the overall volume of the reactor, the winding space and the saturation magnetic flux.

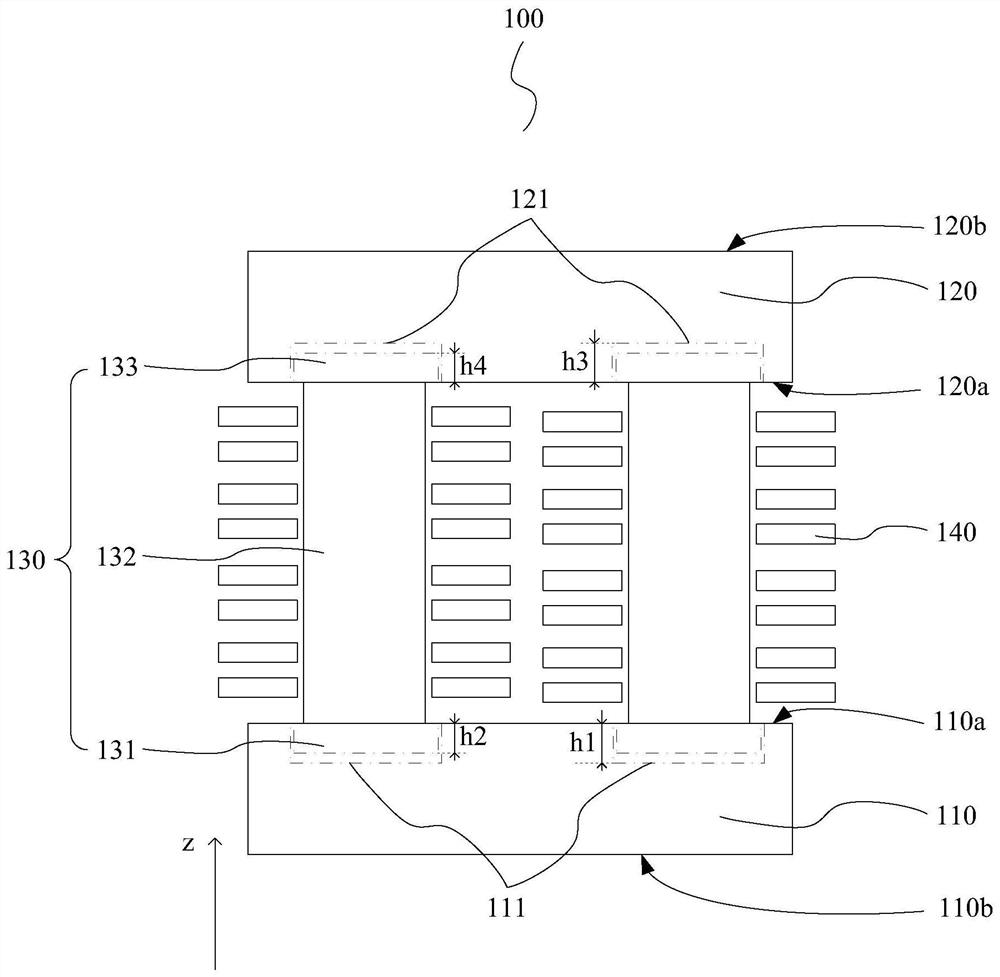

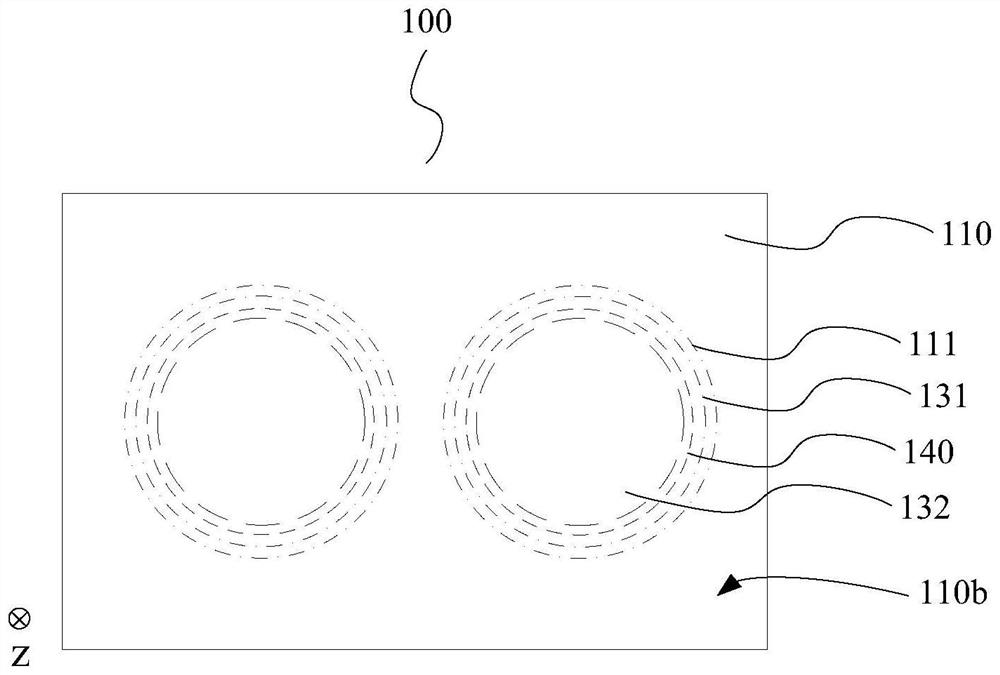

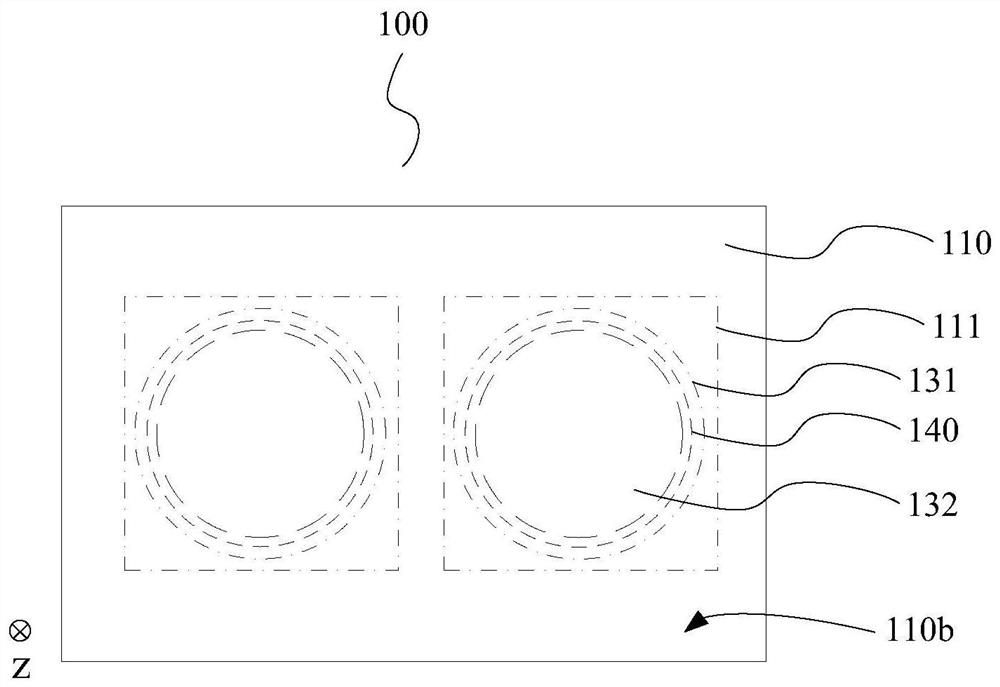

[0034] In order to solve the above technical problems, an embodiment of the present invention provides a reactor, including: a lower iron yoke, the lower iron yoke has a first surface and a second surface opposite to each other, wherein the first surface of the lower iron yoke is opened There is a first groove; an upper iron yoke, the upper iron yoke has an opposite first surface and a second surface, wherein the first surface of the upper iron yoke is provided with a second groove, and the upper iron yoke The first surface is set facing the first surface of the lower iron yoke; the central column located between the lower iron yoke and the upper iron yoke, along the first direction, the central column sequentially includes a first part, a second part and a second part Thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com