A kind of preparation method of graphene-reinforced iron-based composite material

An iron-based composite material and graphene technology, applied in electrolytic coatings, coatings, etc., can solve the problems of easy corrosion, low temperature resistance, and easy peeling of electroplated pure iron coatings, and achieve low cost, easy operation, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

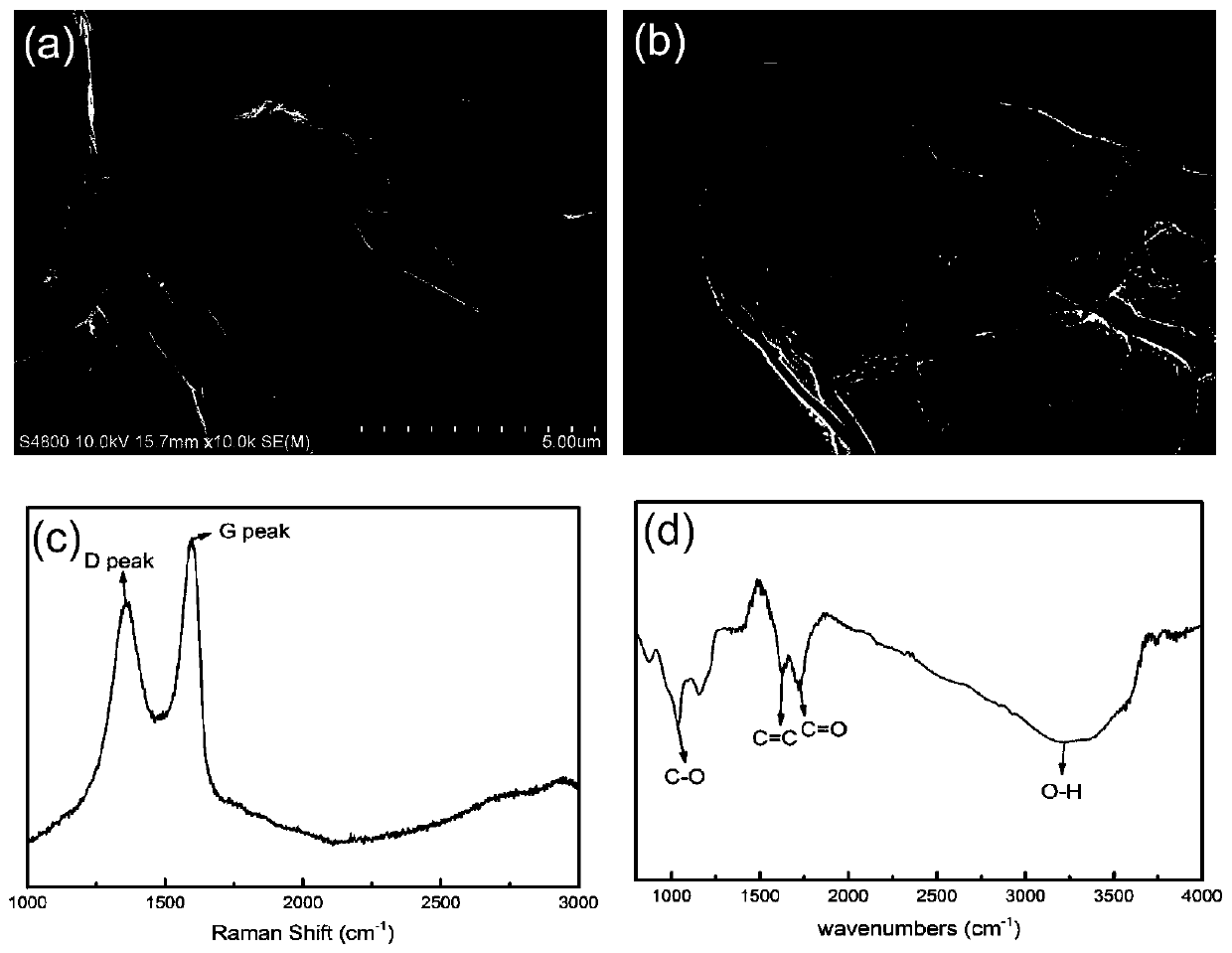

[0023] The average particle size of graphite powder in this embodiment is 325 mesh. The Hummer method is used to prepare graphene oxide. The specific steps are as follows: First, weigh 0.2g graphite and 0.5g K 2 S 2 O 4 , 0.5g P 2 O 5 , Measure 2 ~ 4mL concentrated sulfuric acid, mix together and put it in a water bath equipment at 80°C and continue to stir for 4 hours before taking it out. Add 12mL concentrated sulfuric acid to the treated solution, and slowly add 2g KMnO 4 , And always keep the temperature below 20℃, add KMnO 4 Then, the temperature was kept at 35°C and stirred for 2 hours. Then, 25 mL of distilled water was added, and after the exotherm was completed, the resultant was added to 70 mL of distilled water and maintained at 60-70°C for 1 hour. Add 3mL hydrogen peroxide to the solution to remove excess KMnO 4 , Use alcohol to clean the sample to pH = 7, use ultrasonic dispersion for 1 hour, dry the solution at 40 ~ 70 ℃ to obtain graphene oxide, such as figure 1 ...

Embodiment 2

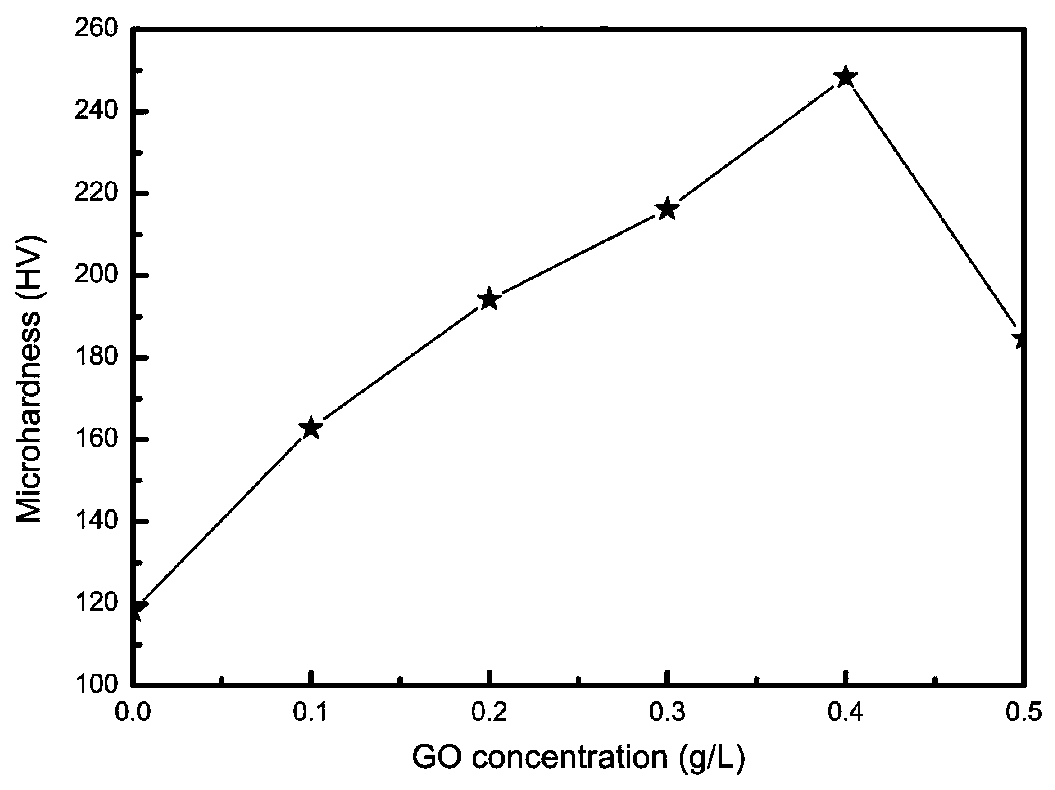

[0025] The experimental conditions for chemical exfoliation of graphene are the same as in Example 1. After the graphene oxide is obtained, it is ground into a finer powder, and 0.05g, 0.1g, 0.15g, 0.2g, and 0.25g GO are respectively weighed and added to 10mL , 20mL, 30mL, 40mL, 50mL of iron plating electrolyte, and then add 5ppm, 10ppm, 15ppm, 20ppm, 25ppm of polyacrylic acid respectively, ultrasonic dispersion for 30min, obtain graphene oxide suspension; add graphene oxide suspension to Sheng In the beaker with the iron plating electrolyte, ultrasonic dispersion is performed for 30 minutes to obtain a graphene oxide suspension with a preset concentration.

Embodiment 3

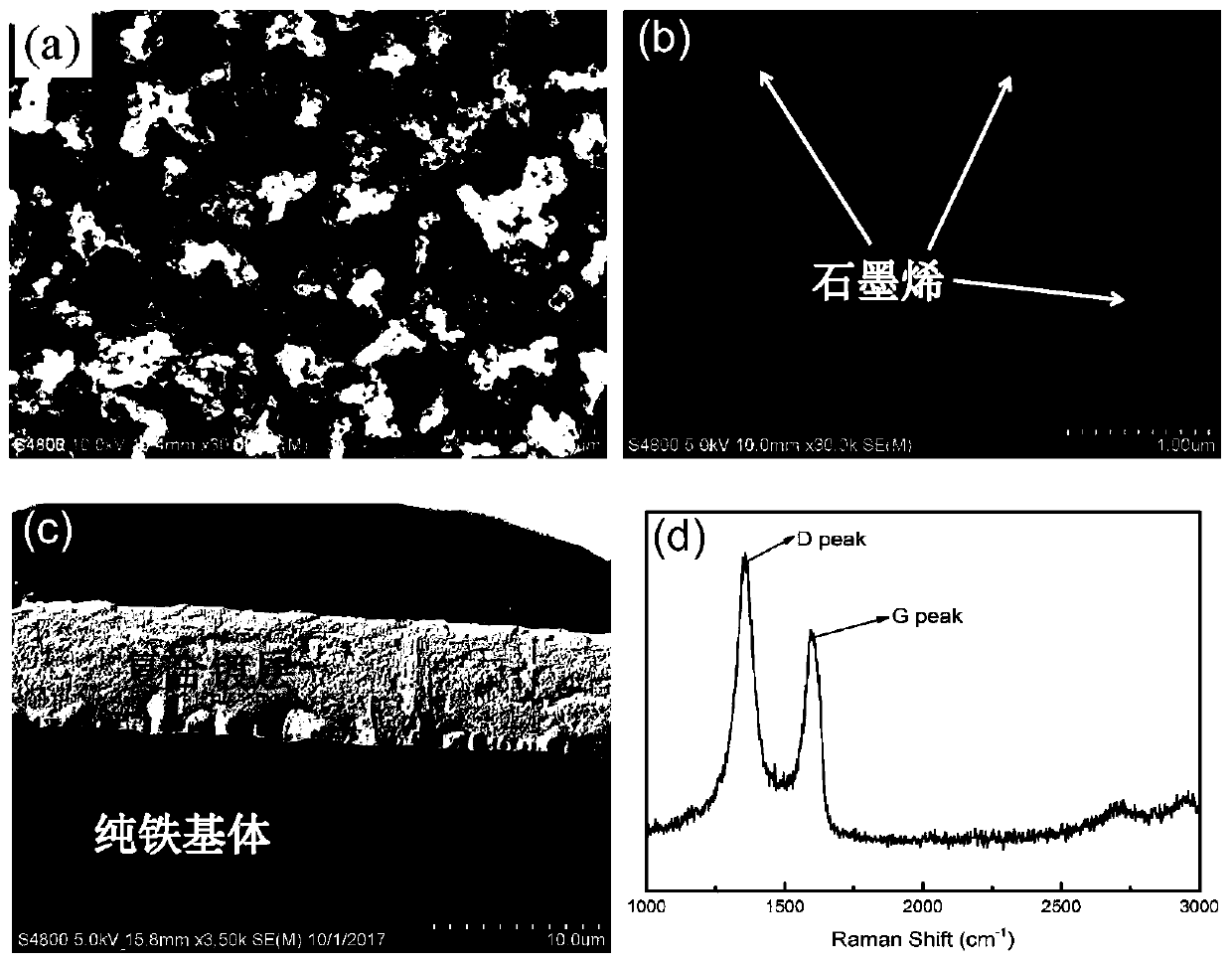

[0027] The experimental conditions of the graphene oxide suspension were the same as in Example 2. After obtaining the 0.1g / L graphene oxide suspension, pure iron sheets were used as the cathode, and stainless steel was used as the anode. The area ratio of the cathode to the anode was 1:2. Before the experiment, the pure iron sheets were polished with 400#, 600#, 800#, 1200# sandpaper respectively, and then etched in 30% (volume fraction) hydrochloric acid for 30s, and then electroplating experiments were carried out. The composition of the iron plating electrolyte: FeCl 2 ·4H 2 O: 350g / L, NH 4 Cl: 30g / L, MnCl 2 : 5g / L, sodium lauryl sulfate 0.1g / L, saccharin 0.1g / L, use dilute hydrochloric acid to adjust the pH to 1-2, the current density is 1A / dm 2 , Temperature 40℃, electroplating time: 20min, magnetic stirring: 1000rpm, GO dosage: 0.1g / L. Finally, graphene reinforced iron-based composite materials are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com