ZnIn2S4 Nanosheet array structure and preparation method thereof

A nanosheet and array structure technology, applied in chemical instruments and methods, electrodes, crystal growth, etc., can solve the problems of low output photocurrent value, low carrier velocity, complex preparation process, etc., and achieve shortened formation time, preparation The effect of low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

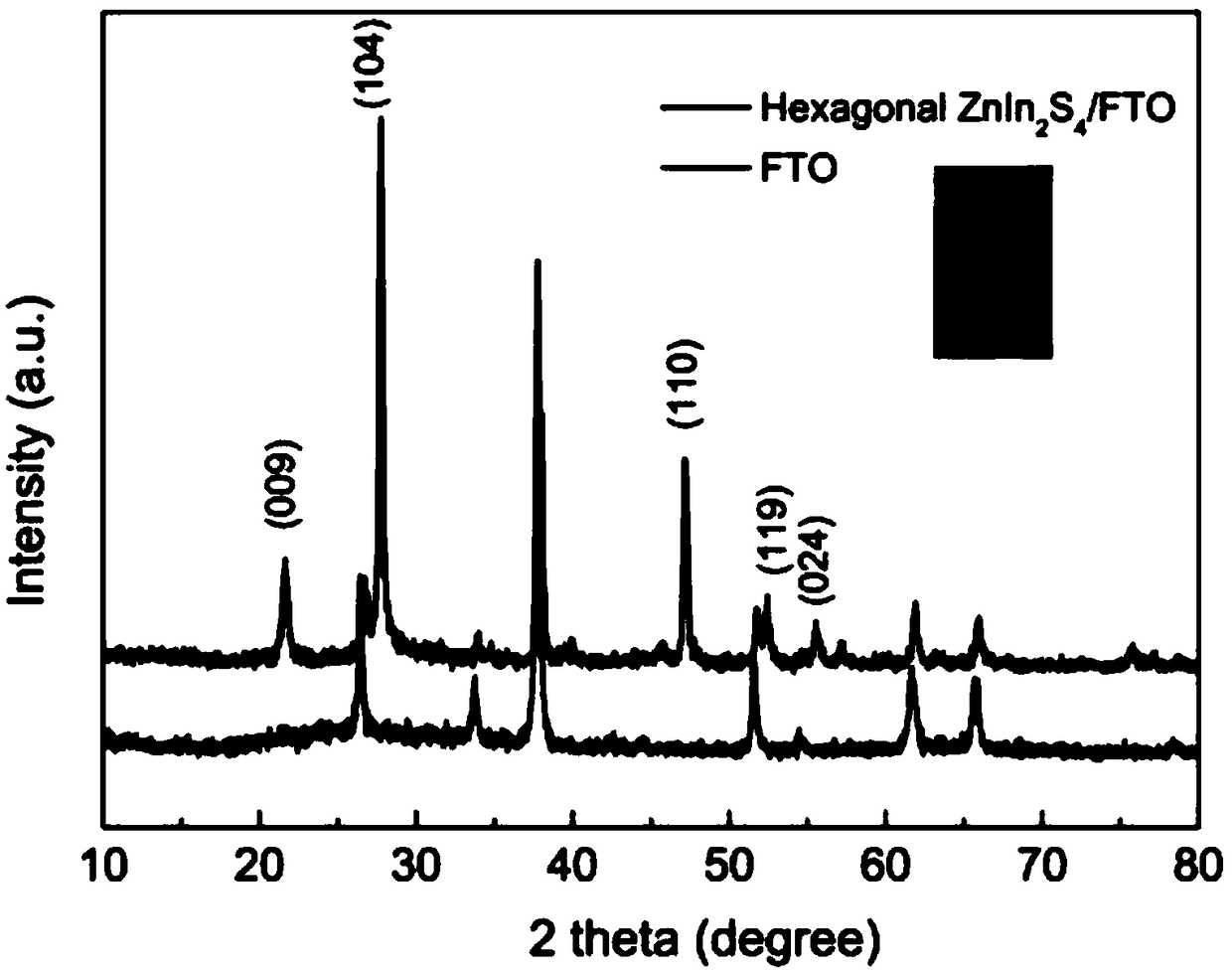

[0039] Zn 2 S 4 The preparation method of the nano-flake array is quickly prepared by a one-step hydrothermal method, and the synthesized nano-flake array is directly and vertically grown on the substrate, and has an ordered single crystal structure.

[0040] The specific steps are as follows:

[0041] a. Dissolve the thiourea of zinc salt and indium salt in deionized water according to the molar ratio of 1:2:4, then add hydrochloric acid, and obtain a clear precursor solution through strong ultrasound and stirring; the zinc salt, indium The purity of the thiourea of the salt is not lower than the analytical grade;

[0042] b. Transfer the above-mentioned clarified precursor solution to the hydrothermal reaction kettle, then add the substrate material, keep the conductive side down, place it, seal it, put it in an oven, set the temperature to 200-250°C, and hydrothermally react for 2-6 hours , and then naturally cooled to room temperature to obtain a flake product;

[...

Embodiment 1

[0049] Embodiment 1: adopt FTO conductive glass substrate;

[0050] Sequentially weigh 0.375 grams of Zn (NO 3 ) 2 ·6H 2 O, 0.73 g InCl 3 4H 2 O. Put 0.455 g of thiourea powder and 1 mL of concentrated hydrochloric acid (37% by mass) into 50 mL of deionized water, and continue stirring to dissolve it. Measure 30mL of the above solution and transfer it to a hydrothermal reaction kettle with a volume of 100mL. Take two pieces of cleaned FTO conductive glass and put them into the reaction kettle, immerse them in the solution, and place them with the conductive side facing down. . Then the reactor was transferred to the oven, the temperature was set at 200°C, and the reaction time was set at 2h. After the reaction was over, the reactor was naturally cooled to room temperature, and the sample was taken out (a layer of yellow film was formed on the conductive glass substrate. layer), washed with deionized water and ethanol three times alternately, and dried at 60°C for 2 hours...

Embodiment 2

[0051] Embodiment 2: adopt ZnO / FTO conductive glass substrate;

[0052] First, a ZnO nanorod array is formed on the FTO conductive glass by hydrothermal synthesis. The specific method is as follows: first, dissolve 0.6g of zinc acetate dihydrate in 50mL of alcohol, stir and ultrasonically evenly, and filter twice to obtain clear seed crystals layer solution, and then spin-coated on the cleaned FTO conductive glass at a speed of 5000rpm, and then heated in a muffle furnace at 350°C for 30min to obtain a conductive glass coated with a ZnO seed layer. At the same time, add 0.75g of zinc nitrate hexahydrate and 0.35g of hexamethylenetetramine into 30mL of deionized water, stir to make it clear, and then transfer the obtained clear aqueous solution to the reaction kettle, and place two Conductive glass covered with a ZnO seed layer placed with the conductive side facing down. Put it in an oven and react at 120°C for 4h.

[0053] Weigh 0.20 g of Zn(NO 3 ) 2 ·6H 2 O, 0.73 g InCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com