A kind of glass fiber reinforced gypsum board imitation wood composite board and preparation method thereof

A glass fiber and gypsum board technology, applied in the field of imitation wood composite boards, can solve the problems of poor fire resistance, potential safety hazards, and easy mold growth of the veneer layer, and achieve the effects of eliminating fire hazards, reducing basis weight and low water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

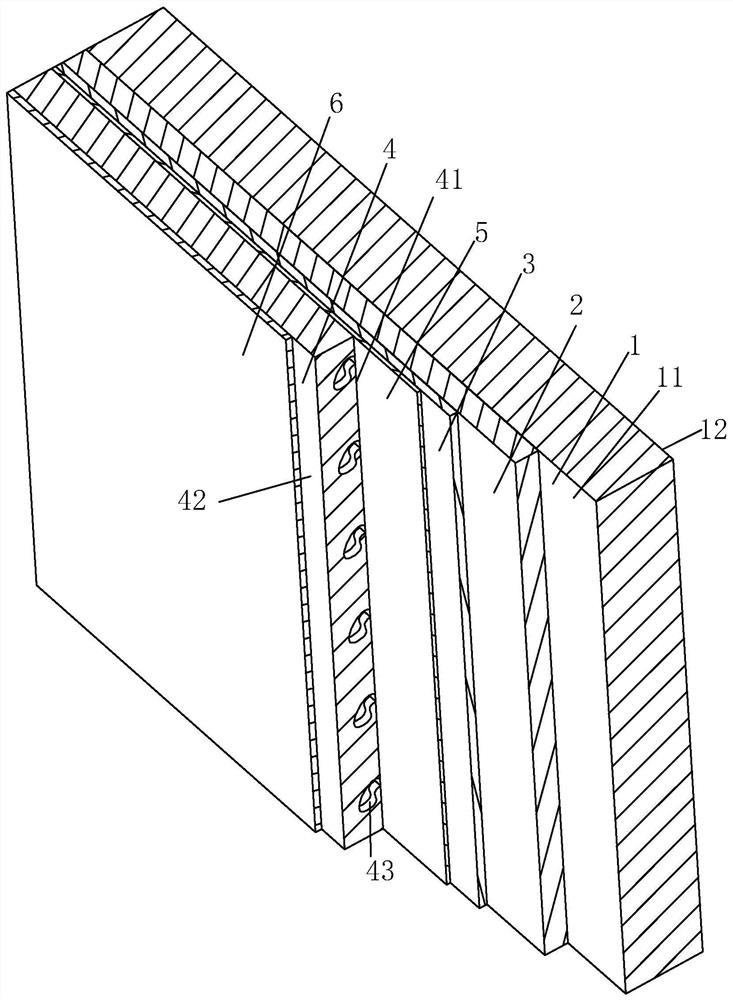

[0054] A kind of glass fiber reinforced gypsum board imitation wood composite board, such as figure 1 shown, including:

[0055] Glass fiber reinforced gypsum board 1, glass fiber reinforced gypsum board 1 comprising a first side 11 and a second side 12;

[0056] A leveling layer 2, the leveling layer 2 covers at least one side of the glass fiber reinforced gypsum board 1;

[0057] A sealing layer 3, the sealing layer 3 covers the surface of the leveling layer 2;

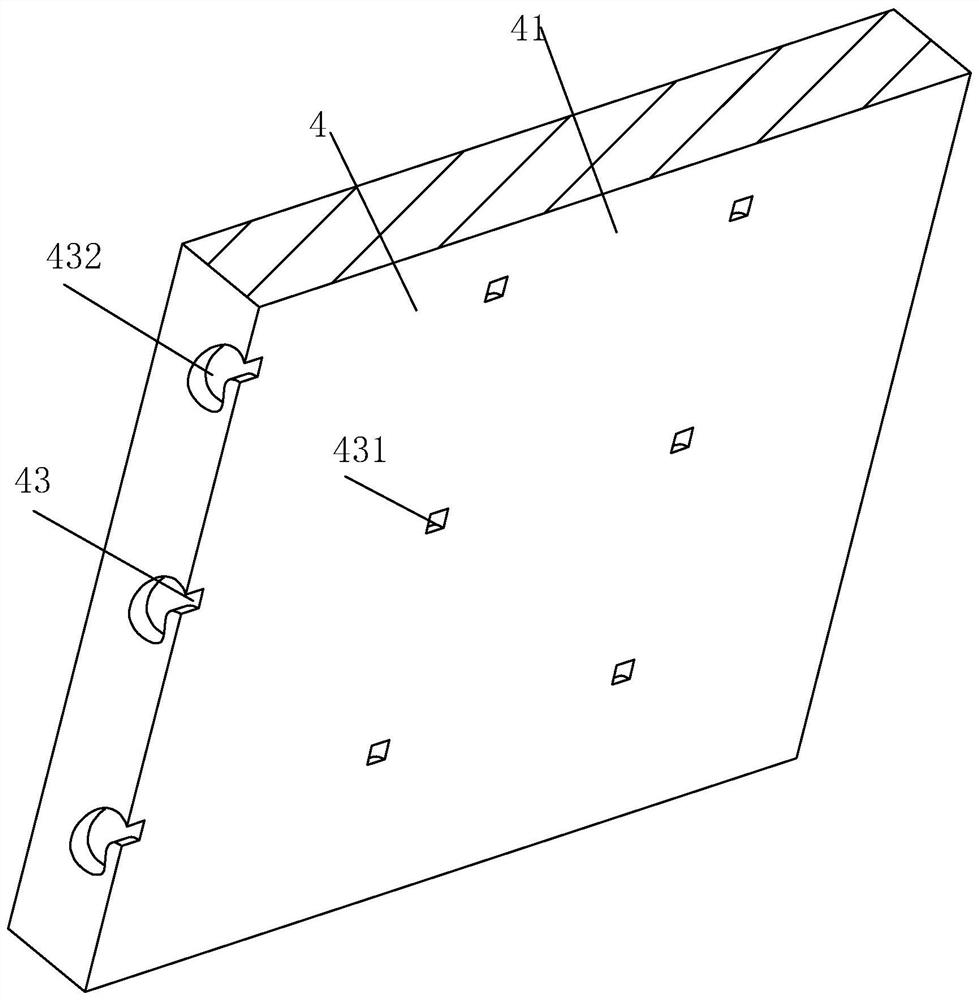

[0058] The fireproof layer 4 covers the surface of the sealing layer 3, further improving the fireproof performance of the imitation wood composite board. The fireproof layer 4 includes a first fireproof side 41 and a second fireproof side 42, and the first fireproof side 41 is bonded to the sealing layer 3 through the bonding layer 5;

[0059] The imitation wood paint layer 6, the imitation wood paint layer 6 covers the surface of the fireproof layer 4.

[0060] The imitation wood paint has the effect of imitatin...

Embodiment 2

[0069] A glass fiber reinforced gypsum board imitation wood composite board. The difference between embodiment 2 and embodiment 1 is that a water bag is placed in the middle of the hollow glass beads in the storage tank, and potassium chloride particles are also filled with water. The specific heat capacity is relatively large, and it has a certain heat preservation effect. When the fire is very large, it can also be used to extinguish the fire; the water bag is melted by high temperature or is burned by fire and dissolves potassium chloride. The dissolved heat of potassium chloride can also play a role in cooling down and extinguishing the fire. Effect, further improves the fire performance of the imitation wood composite board prepared by the present invention.

preparation Embodiment 1

[0071] A kind of method for preparing glass fiber reinforced gypsum board imitation wood composite board in embodiment 1, comprises the following steps:

[0072] Step 1. Stir gypsum powder, sodium bicarbonate and white latex evenly at room temperature to form a composite mortar for later use. Place the glass fiber reinforced gypsum board on a horizontal platform to level the glass fiber reinforced gypsum board. The first side and / or the second side of the board shall be leveled. After the gypsum of the first compound mortar is dry, the second leveling construction shall be carried out. Scrape the putty, and sand it smooth after the putty layer is dry.

[0073] Step 2, constructing a sealing layer on the surface of the leveling layer, that is, using a roller brush to coat the leveling layer with two varnishes on the surface of the putty layer to form a varnish layer;

[0074] Step 3, preparing a fireproof layer, opening holes on the glass magnesium board, putting in hollow gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com