Porous Ti-based nano-composite material for hard tissue material and preparation method and application thereof

A composite material and porous titanium technology, applied in the direction of tissue regeneration, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of unsatisfactory biological activity, inability to reduce adverse effects, poor comprehensive mechanical properties, etc., and achieve strong binding force , Good dispersibility, combined compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0082] The present invention also provides a method for preparing a porous titanium-based composite material, comprising the following steps:

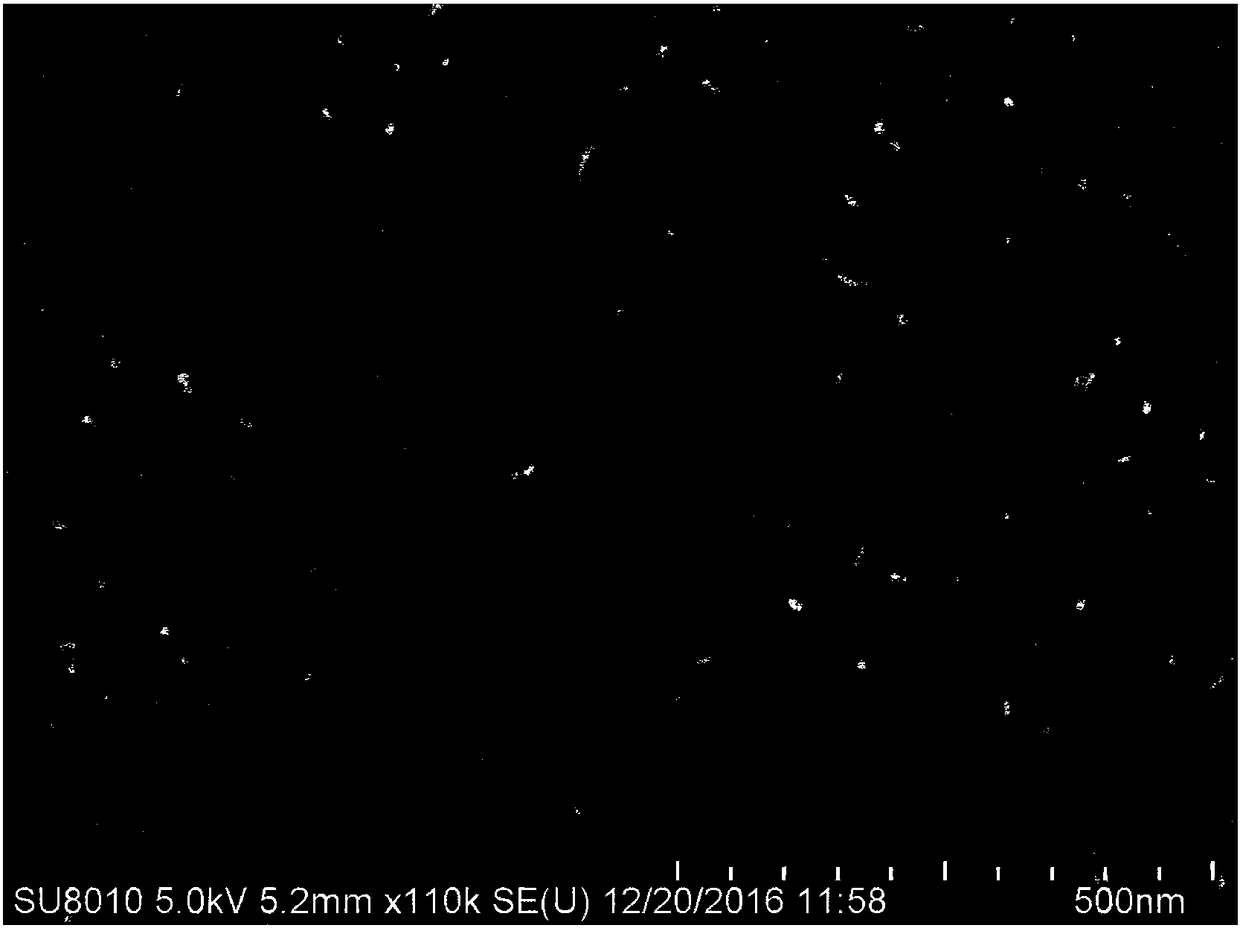

[0083] 1) After the pretreated titanium-based material is subjected to an anodic oxidation process and annealing treatment, a titanium-based material with a porous structure surface is obtained;

[0084] After mixing chitosan and vancomycin mixed solution, calcium salt, phosphorus salt and water, adjust the pH value to obtain the first mixed solution;

[0085] 2) Electrodepositing the titanium-based material with a porous structure surface and the first mixed solution obtained in the above steps to obtain a semi-finished product;

[0086] 3) The semi-finished product obtained in the above steps is soaked in alkali to obtain a porous titanium-based composite material.

[0087] The selection, proportion and corresponding optimization principles of the raw materials in the preparation method in the present invention are consistent with t...

Embodiment 1

[0134] The titanium alloy with a size of 40×20×1mm was polished with sandpaper in sequence, and then ultrasonically cleaned in acetone, absolute ethanol and deionized water for 10 minutes respectively. Electrochemical polishing is carried out in the polishing solution of phosphoric acid: sulfuric acid: water = 1:3:10 (volume ratio), and the electrochemical polishing is carried out in an oil bath device at 85°C, the stirring speed is 800r / min, and the constant current method is used for polishing. The density is 25A / dm 2 , the polishing time is 10s, and the polished sample is ultrasonically cleaned with deionized water for 10 minutes. After completion, it is taken out, rinsed, and dried with cold air. area and prevent edge polarization.

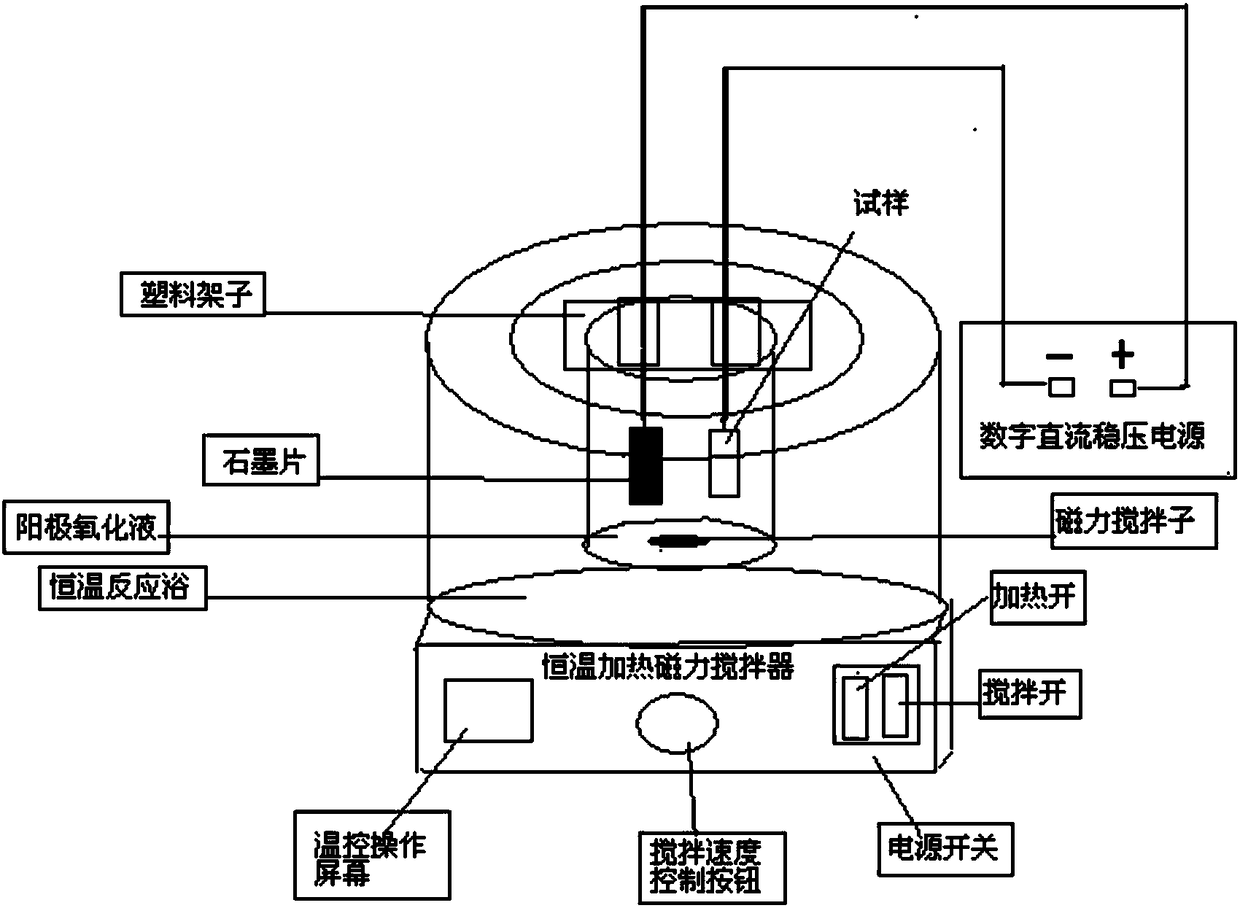

[0135] The anodic oxidation adopts the constant voltage method, the hydrofluoric acid solution is used as the electrolyte, the hydrofluoric acid concentration is 0.5wt%, the oxidation voltage is 10V, the oxidation time is 1h, the oxidation te...

Embodiment 2

[0149] The titanium alloy with a size of 40×20×1mm was polished with sandpaper in sequence, and then ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes respectively. Electrochemical polishing is carried out in the polishing solution of phosphoric acid: sulfuric acid: water = 1:3:10 (volume ratio), and the electrochemical polishing is carried out in an oil bath device at 87°C, the stirring speed is 1000r / min, and the constant current method is used for polishing. The density is 35A / dm 2 , the polishing time is 15s, and the polished sample is ultrasonically cleaned with deionized water for 13 minutes. After the completion, take it out, rinse it, and dry it with cold air. area and prevent edge polarization.

[0150] Anodic oxidation adopts constant voltage method, hydrofluoric acid solution is used as electrolyte, the concentration of hydrofluoric acid is 0.5wt%, oxidation voltage is 20V, oxidation time is 1h, oxidation temperature is 25°C, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com