An enhanced polycrystalline Ni 3 Heat Treatment Methods for Deformation Stability of Al-Based Superalloys

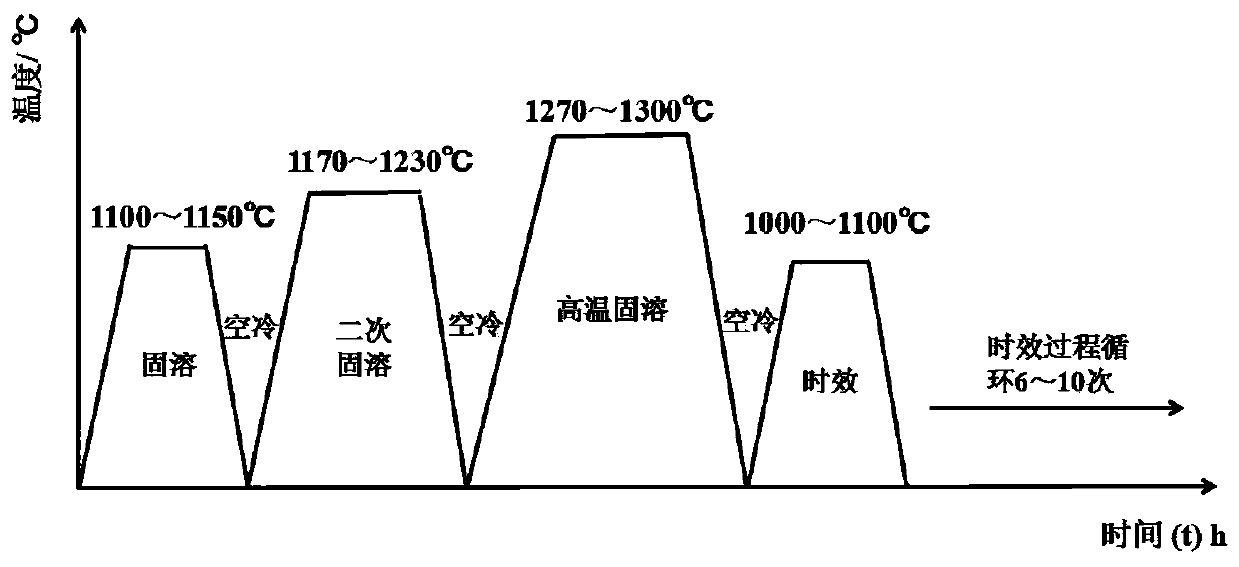

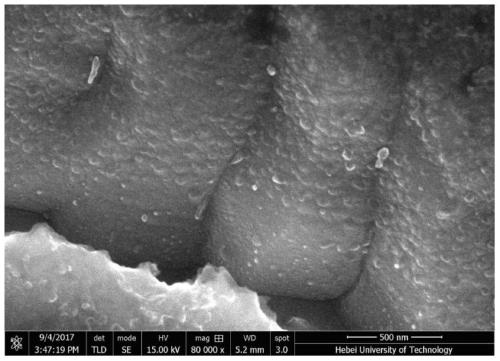

A heat treatment method and superalloy technology, applied in the field of superalloy structural materials, can solve the problems of poor deformation stability and low initial melting temperature, and achieve the effect of strengthening two-phase interface and improving deformation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step, raw material preparation:

[0028] Select as-cast polycrystalline Ni in the following composition range according to the mass fraction 3 Al-based superalloy, its specific composition is C element: 0.1%; Cr element: 7%; Al element: 8.8%; Ti element: 1.2%; Hf element: 0.7%; W element: 2%; Mo element: 5.5% %; B element: 0.03%; Fe element: 2.2%; Si element: 0.23%; Mn element: 0.23%; shape, then ultrasonically cleaned in alcohol for 10 minutes, and dried for use; put the corundum crucible at 700°C for 3 hours to dehumidify, and stand for use.

[0029] The second step, solution treatment:

[0030] First, the temperature of the box furnace was raised to 1100°C. After the temperature stabilized, the crucible containing the sample was placed in the uniform temperature zone of the box furnace, and argon gas was introduced for gas protection. The sample was kept in the box furnace for 6 hours, the gas protection was stopped, and then the crucible containing the ...

Embodiment 2

[0041] The first step, raw material preparation:

[0042] Select as-cast polycrystalline Ni in the following composition range according to the mass fraction 3 Al-based superalloy, the specific composition is C element: 0.1%; Cr element: 7%; Al element: 8.8%; Ti element: 1.2%; Hf element: 0.7%; W element: 2%; Mo element: 5.5% ; B element: 0.03%; Fe element: 2.2%; Si element: 0.23%; Mn element: 0.23%; , and then ultrasonically cleaned in alcohol for 10 minutes, and dried for use; put the corundum crucible at a temperature of 700°C for 3 hours to dehumidify, and stand for use.

[0043] The second step, solution treatment:

[0044] First, the temperature of the box-type furnace was raised to 1130°C. After the temperature stabilized, the crucible containing the sample was placed in the uniform temperature zone of the box-type furnace, and argon gas was introduced for gas protection. The sample was kept in the box furnace for 8 hours, the gas protection was stopped, and then the...

Embodiment 3

[0054] The first step, raw material preparation:

[0055] Select as-cast polycrystalline Ni in the following composition range according to the mass fraction 3 Al-based superalloy, the specific composition is C element: 0.1%; Cr element: 7%; Al element: 8.8%; Ti element: 1.2%; Hf element: 0.7%; W element: 2%; Mo element: 5.5% ; B element: 0.03%; Fe element: 2.2%; Si element: 0.23%; Mn element: 0.23%; , and then ultrasonically cleaned in alcohol for 10 minutes, and dried for use; put the corundum crucible at a temperature of 700°C for 3 hours to dehumidify, and stand for use.

[0056] The second step, solution treatment:

[0057] First, the temperature of the box-type furnace was raised to 1150°C. After the temperature stabilized, the crucible containing the sample was placed in the uniform temperature zone of the box-type furnace, and argon gas was introduced for gas protection. The sample is kept in the box furnace for 10 hours, the gas protection is stopped, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com