Continuous casting billet formed A387Gr11C12 steel plate and production method thereof

A technology of a387gr11cl2 and production method, which is applied in the field of metallurgy, can solve problems such as fluctuations in performance and difficulty in ensuring plate shape, and achieve the effects of good plate shape, mass production, and excellent internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

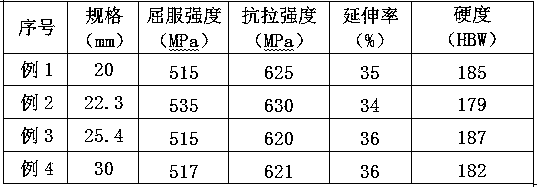

Examples

Embodiment 1

[0019] The thickness of the A387Gr11Cl2 steel plate in this embodiment is 20 mm, and its chemical composition and mass percentage are: C: 0.09%, Si: 0.86%, Mn: 0.73%, P: 0.008%, S: 0.005%, Cr : 1.56%, Mo: 0.60%, Sn: 0.002%, the balance is Fe and unavoidable impurities.

[0020] The production method of the continuous casting billet finished A387Gr11Cl2 steel plate of this embodiment comprises: steelmaking, continuous casting, heating, rolling and heat treatment process, heat treatment process adopts normalizing+tempering process, and concrete process step is as follows:

[0021] (1) Steelmaking process: Converter smelting, LF furnace refining, VD vacuum treatment process; LF furnace refining white slag retention time 23min, VD vacuum treatment vacuum degree 65Pa, vacuum retention time 20min;

[0022] (2) Continuous casting process: In the continuous casting process, an arc continuous casting machine is used to control the continuous casting casting speed to 0.6m / min, and the c...

Embodiment 2

[0028] The thickness of the A387Gr11Cl2 steel plate produced by continuous casting in this embodiment is 22.3mm, and its chemical composition and mass percentage are: C: 0.15%, Si: 0.48%, Mn: 0.40%, P: 0.007%, S: 0.004%, Cr: 0.94%, Mo: 0.55%, Sn: 0.003%, and the balance is Fe and unavoidable impurities.

[0029] The production method of the continuous casting billet finished A387Gr11Cl2 steel plate of this embodiment comprises: steelmaking, continuous casting, heating, rolling and heat treatment process, heat treatment process adopts normalizing+tempering process, and concrete process step is as follows:

[0030] (1) Steelmaking process: Converter smelting, LF furnace refining, VD vacuum treatment process; LF furnace refining white slag retention time 25min, VD vacuum treatment vacuum degree 64Pa, vacuum retention time 25min;

[0031] (2) Continuous casting process: In the continuous casting process, an arc continuous casting machine is used to control the continuous casting c...

Embodiment 3

[0037] The thickness of the A387Gr11Cl2 steel plate produced by continuous casting in this embodiment is 25.4mm, and its chemical composition and mass percentage are: C: 0.12%, Si: 0.52%, Mn: 0.46%, P: 0.007%, S: 0.005%, Cr: 1.35%, Mo: 0.70%, Sn: 0.002%, and the balance is Fe and unavoidable impurities.

[0038] The production method of the continuous casting slab into a material A387Gr11Cl2 steel plate in this embodiment comprises: steelmaking, continuous casting, heating, rolling and heat treatment process, the heat treatment process adopts normalizing+tempering process, and the specific process steps are as follows:

[0039] (1) Steelmaking process: Converter smelting, LF furnace refining, VD vacuum treatment process; LF furnace refining white slag retention time 26min, VD vacuum treatment vacuum degree 62Pa, vacuum retention time 23min;

[0040] (2) Continuous casting process: In the continuous casting process, an arc continuous casting machine is used to control the conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com