Method for manufacturing electrode window and semiconductor device with electrode window

A manufacturing method and electrode window technology, applied in the field of semiconductors, can solve the problems of high manufacturing difficulty and high lithography precision requirements, and achieve the effect of low etching precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

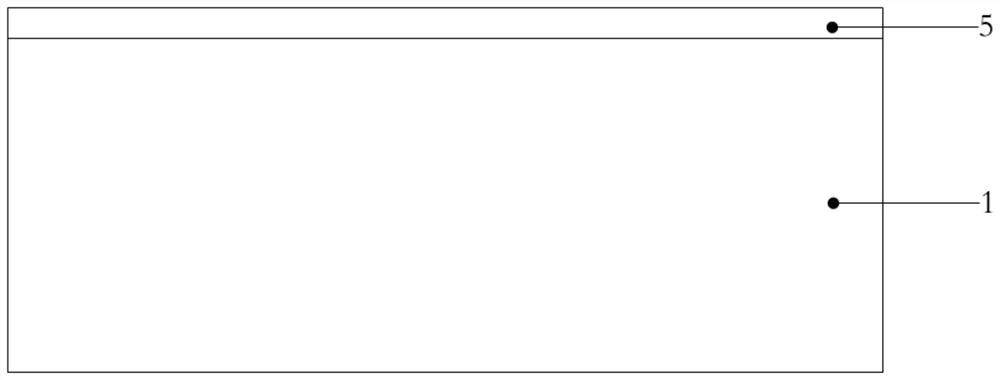

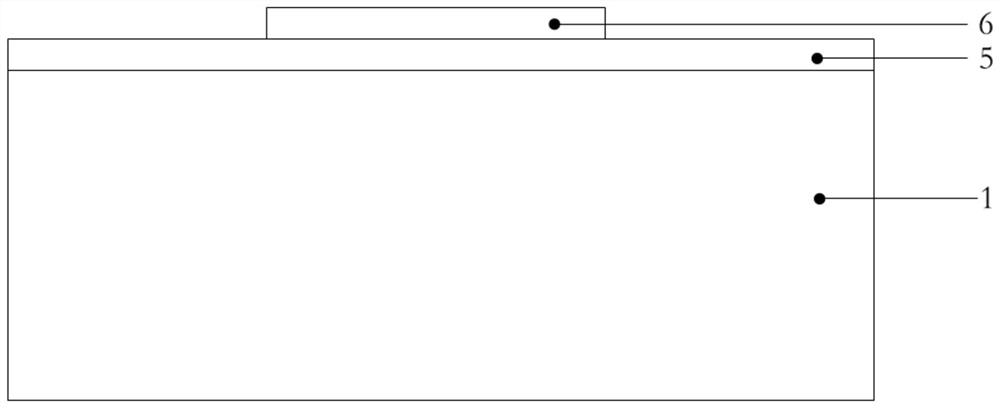

[0061] This embodiment provides a method for manufacturing the electrode window 7, comprising the following steps:

[0062] S1, on the first surface 1a of the semiconductor body 1, make the protruding protruding portion 2, the outer surface of the protruding portion 2 has a top region 2a opposite to the first surface 1a and a vertical wall connected to both ends of the top region 2a. Area 2b; as follows:

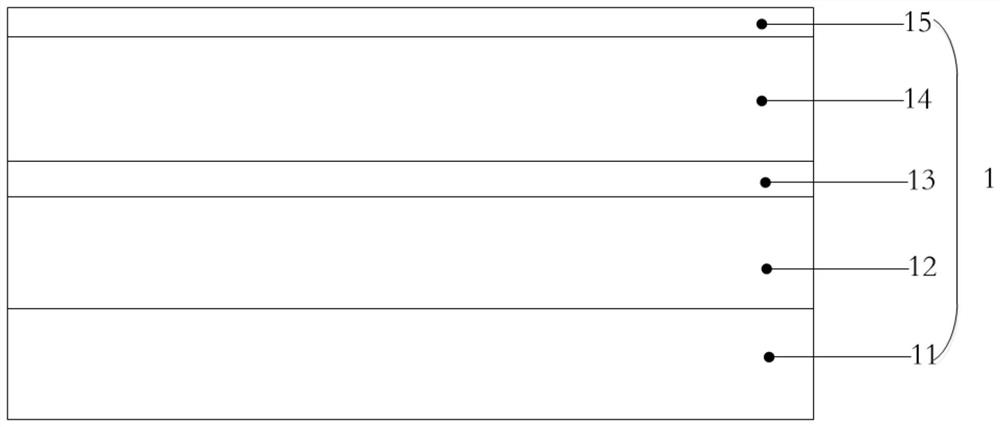

[0063] S11, such as figure 1 As shown, a semiconductor body 1 having a first surface 1a is provided, and the semiconductor body 1 is obtained by sequentially growing a first confinement layer 12, an active layer 13, a second confinement layer 14 and an electrode contact layer 15 on a substrate 11, The side surface of the electrode contacting away from the substrate 11 is the first surface 1a. The epitaxial growth method can choose vapor phase epitaxy (MOCVD), molecular beam epitaxy (MBE), low pressure chemical vapor deposition (LPCVD) and so on. Materials for forming the ...

Embodiment 2

[0080] This embodiment provides a method for manufacturing a semiconductor device with an electrode window 7, comprising the following steps:

[0081] 1. Obtain the semiconductor body 1 with the electrode window 7 opened by the manufacturing method provided in the first embodiment.

[0082] 2. If Figure 13 As shown, the metal electrode 8 is made on the side of the semiconductor body 1 where the raised portion 2 is formed. The deposition method can be electron gun vacuum evaporation, thermal evaporation, spin coating, sputtering, etc., to form a metal electrode 8 located in the electrode window 7. The first metal electrode 81, the second metal electrode 83 located on the insulating layer 3 covering the first surface 1a, and extending from the surface of the first metal electrode 81 to the outside of the vertical region 2b of the protrusion 2 to the surface of the second electrode 83 The metal connection part 82. Specifically, the metal connection portion 82 of the metal elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com