Liquid crystal aligning agent, liquid crystal alignment film, and liquid crystal display element

A technology of liquid crystallinity and performance, applied in the field of liquid crystal display elements, it can solve the problems of dust, static electricity, inability to achieve uniform alignment of liquid crystals, and uniform rubbing of liquid crystal alignment films, and achieve high efficiency and excellent electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0228] [Preparation of polymer composition]

[0229] The polymer composition of the present invention is obtained by bringing a composition containing a photosensitive side chain type polymer as the component (A) and an organic solvent as the component (B) into contact with an ion exchange resin.

[0230] As the ion exchange resin, either a cation exchange resin or an anion exchange resin can be used.

[0231] The cation exchange resin is not particularly limited, and may be a strongly acidic cation exchange resin or a weakly acidic cation exchange resin. Examples of commonly used, for example, commercially available hydrogen-form cation exchange resins are shown below. Examples of strong acid ion exchange resins include ion exchange resins having sulfinic acid groups (sulfonated products of cross-linked polystyrene such as styrene-divinylbenzene copolymers), sulfinic acid group (or -CF 2 CF 2 SO 3H group), Nafion (manufactured by DuPont), DIAION SK series, DIAION UBK seri...

Embodiment

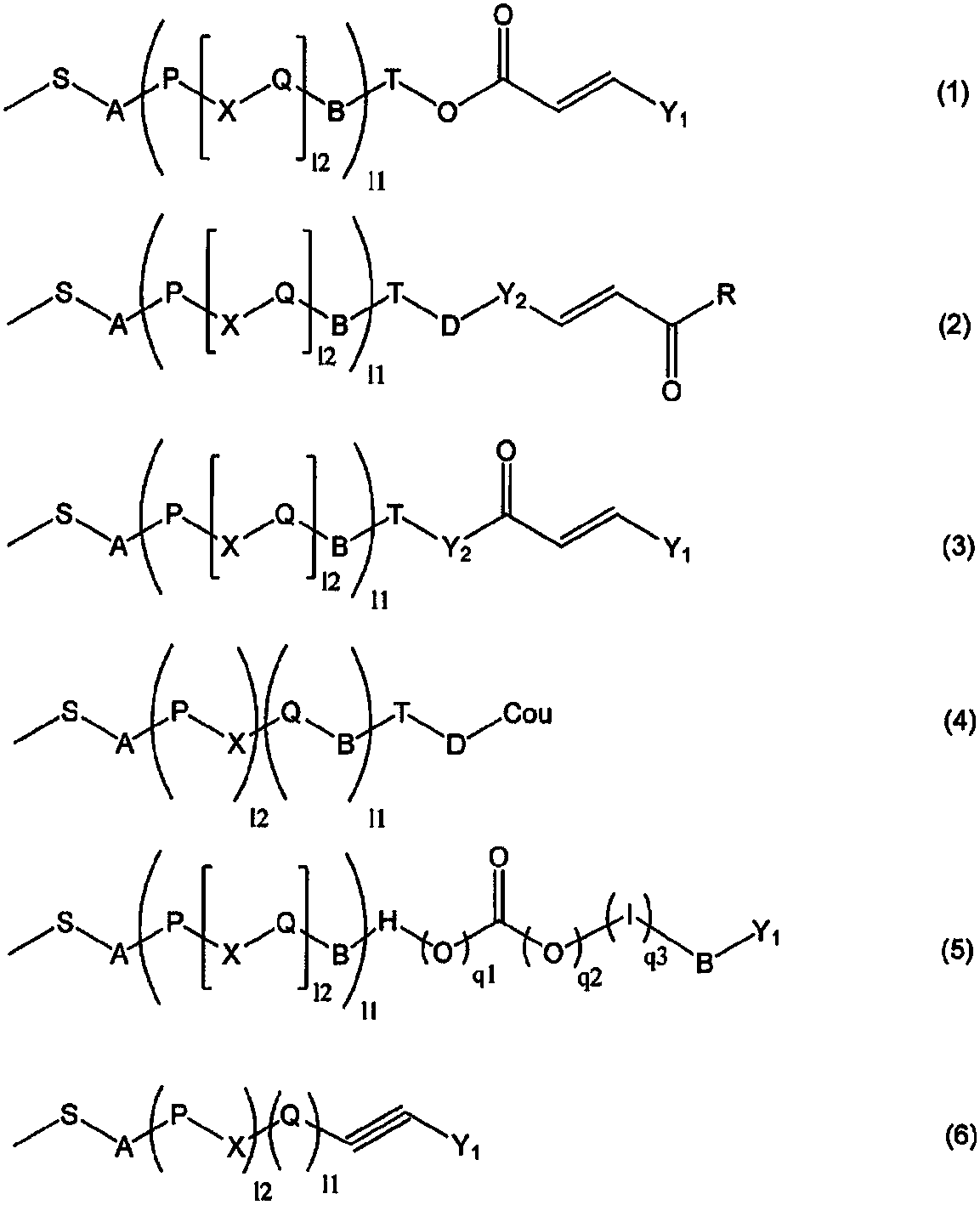

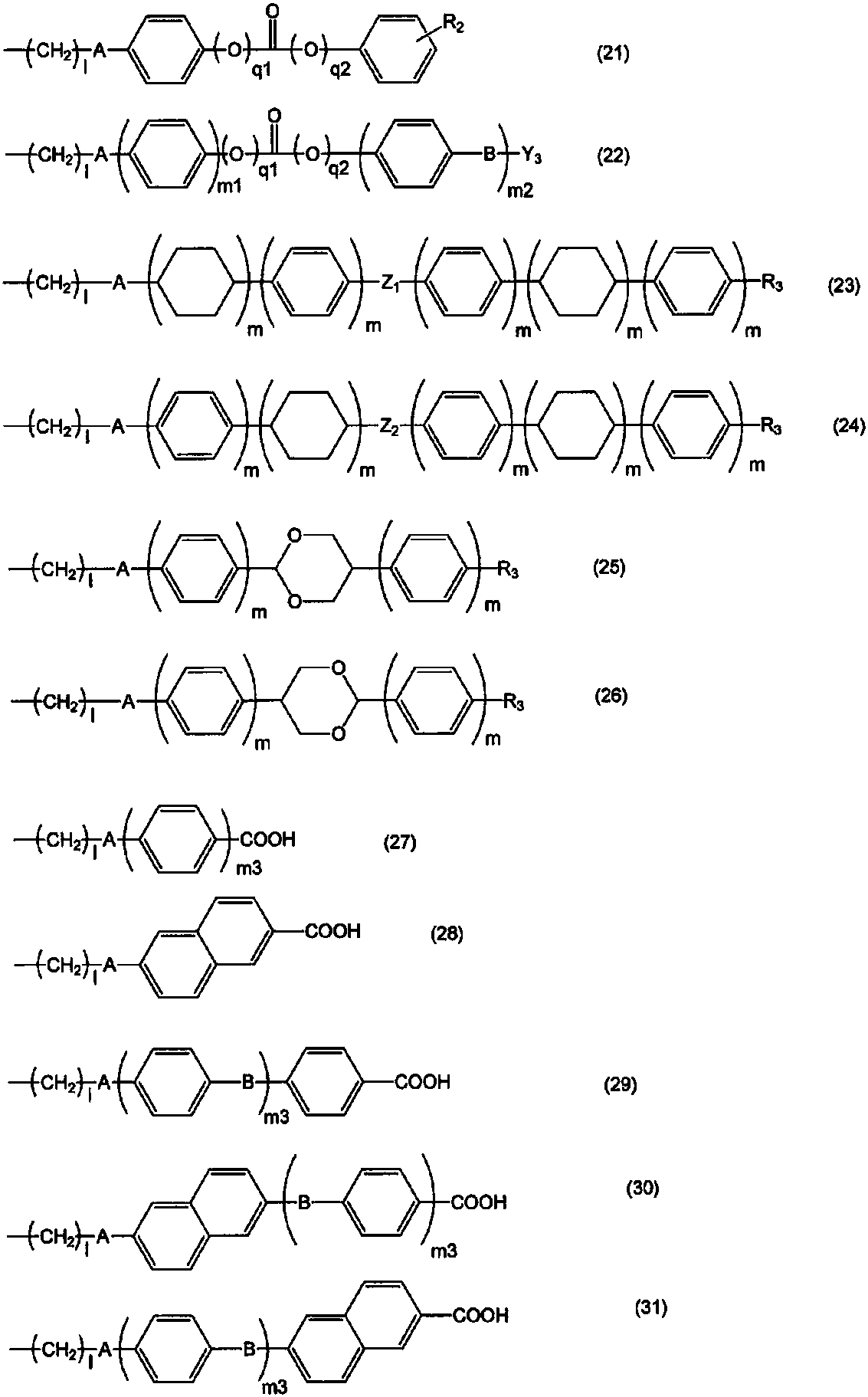

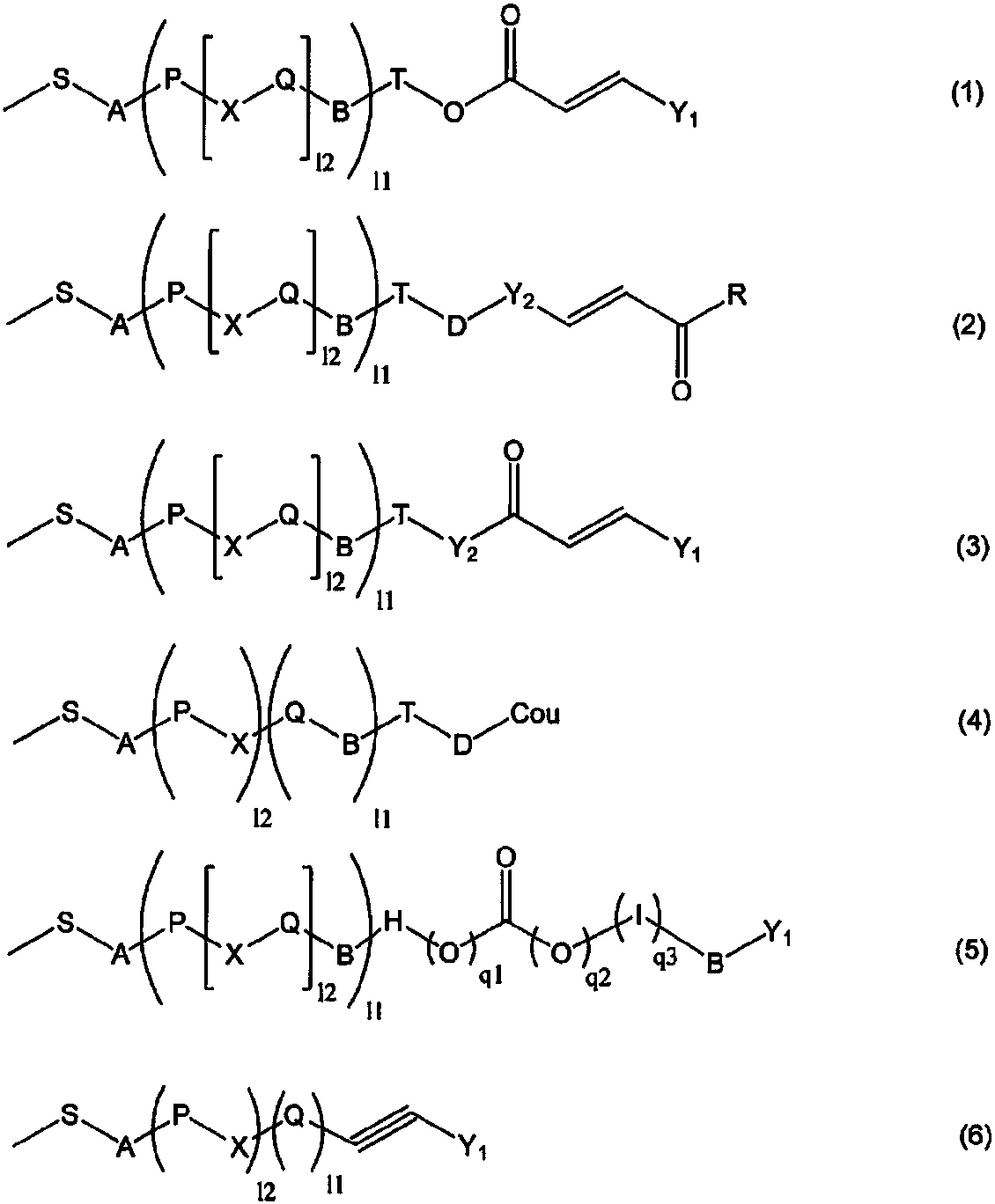

[0302] The methacrylic monomers M1 and M2 used in the examples are shown below.

[0303] In addition, M1 and M2 were respectively synthesized as follows. That is, M1 was synthesized by the synthesis method described in the patent document (WO2011-084546). M2 was synthesized by the synthesis method described in the patent document (Japanese Patent Laid-Open No. 9-118717).

[0304]

[0305] In addition, the abbreviations of the reagents used in this example are shown below.

[0306] (Organic solvents)

[0307] THF: Tetrahydrofuran.

[0308] NMP: N-ethyl-2-pyrrolidone.

[0309] BCS: Butyl Cellosolve

[0310] (polymerization initiator)

[0311] AIBN: 2,2'-azobisisobutyronitrile.

[0312]

[0313] M1 (3.98 g) and M2 (5.51 g) were dissolved in THF (40.0 g), and after degassing with a diaphragm pump, AIBN (0.24 g) was added and degassed again. Then, it was made to react at 60 degreeC for 6 hours, and the polymer solution of the methacrylate was obtained. This polymer solu...

Embodiment 2~8

[0319] Polymer solution PC1 was processed by the method similar to Example 1 with the ion-exchange resin quantity shown in Table 1, and the liquid crystal aligning agents T2-T8 of Examples 2-8 were obtained.

[0320] [Table 1]

[0321]

[0322]

[0323] After filtering the liquid crystal aligning agent (T1) obtained in Example 1 with a filter of 0.45 μm, it was spin-coated on a glass substrate with a transparent electrode, and dried on a hot plate at 70° C. for 90 seconds to form a film with a film thickness of 100 nm. Liquid crystal alignment film. Next, irradiate the coating surface with 15mJ / cm of 313nm ultraviolet rays through a polarizing plate 2 Then, it heated for 10 minutes on the hot plate of 140 degreeC, and obtained the board|substrate with a liquid crystal aligning film. Prepare two such substrates with a liquid crystal alignment film, place a 6 μm spacer on the liquid crystal alignment film surface of one substrate, combine the two substrates so that the ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com