Engineering bacteria for producing D-tryptophan and construction method and purpose of producing D-tryptophan

A construction method and tryptophan technology, applied in the field of D-tryptophan production, can solve the problems of unstable chemical properties of N-acetyl-L-tryptophan, multiple materials, loss, etc., and improve yield and product quality , The effect of simplifying the production process and saving fermentation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

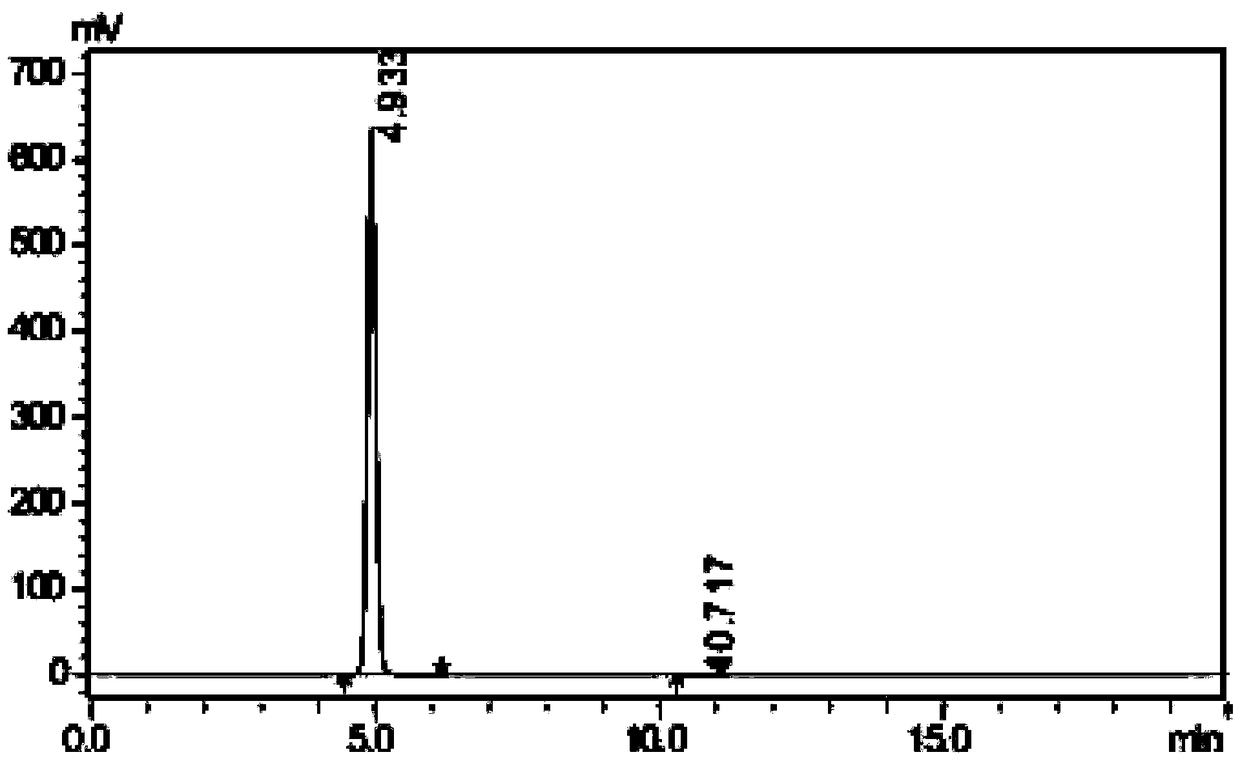

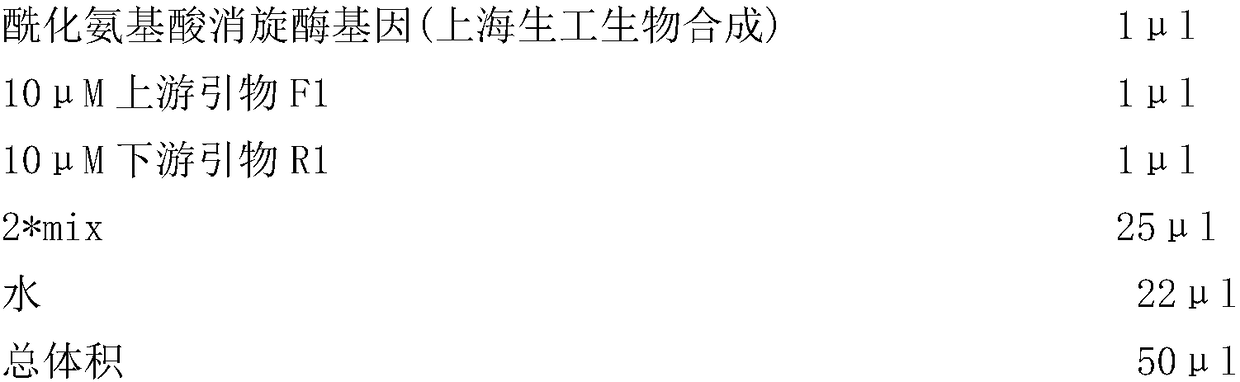

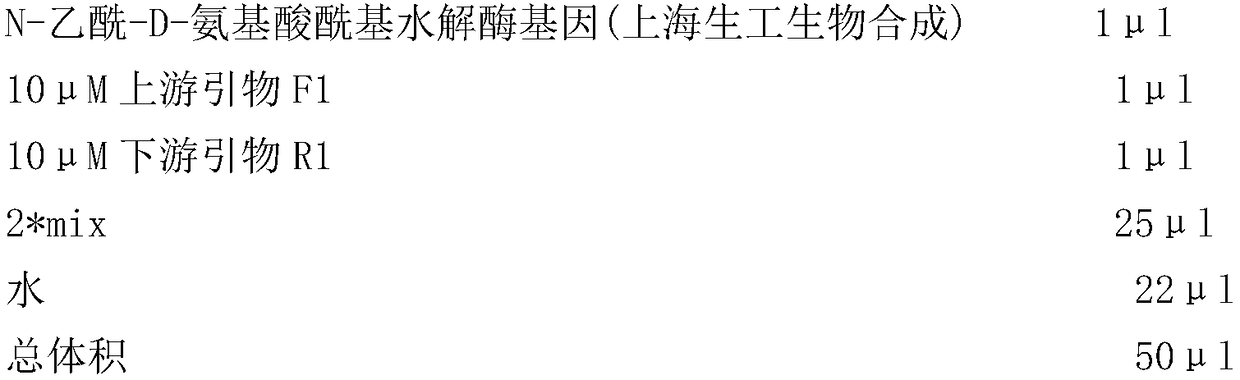

[0017] Cloning of an acylated amino acid racemase gene and an N-acetyl-D-amino acid acyl hydrolase gene.

[0018] 1. First, synthesize the acylated amino acid racemase gene and the N-acetyl-D-amino acid acyl hydrolase gene with reference to the sequence of the gene database and design primers:

[0019] The gene sequence of acylated amino acid racemase was synthesized in Shanghai Sangon Biotechnology Co., Ltd. with reference to GenBank: D30738.1.

[0020] The gene sequence of N-acetyl-D-amino acid acyl hydrolase was synthesized in Shanghai Sangon Biotechnology Co., Ltd. according to GenBank: D45918.1.

[0021] Primers were designed as follows:

[0022] F2: catat catatg tcccaatccgattc (Add ndeI site) SEQ ID NO.3

[0023] R2: catat ggatcc ctatcaggcggccgt (add bamhI site) SEQ ID NO.4

[0024] F1: catat catatg aaactcagcggtgtg (Add ndeI site) SEQ ID NO.5

[0025] R1: catat ggatcc ctactacgaaccga (add bamhI site) SEQ ID NO.6

[0026] Primers F1 and R1 are used to amplify ...

Embodiment 2

[0048] The error-prone PCR product of the acylated amino acid racemase gene and the error-prone PCR product of the N-acetyl-D-amino acid acyl hydrolase gene obtained in Example 1 were respectively linked to the pET28a vector.

[0049] 1. Use the restriction endonucleases ndeI and bamhI to digest the product of step 2 of Example 1 respectively, and the reaction system is as follows:

[0050]

[0051] The reaction conditions were 37°C for 3 hours. Use the Shanghai Sangong SanPrep Column PCR Product Purification Kit to recover the digested product.

[0052] The product of Step 3 of Example 1 was used instead of the product of Step 2 of Example 1 in this example to perform the same operation to recover the enzyme-cleaved product.

[0053] 2. Digest the pET28a vector with restriction enzymes ndeI and bamhI. The reaction system is as follows:

[0054]

[0055]

[0056] The reaction conditions were 37°C for 3 hours. Shanghai Sangong SanPrep Column PCR Product Purification...

Embodiment 3

[0063] Example 3: Expression of acylated amino acid racemase and N-acetyl-D-amino acid acyl hydrolase, and selection of optimal mutant genes.

[0064]The expression vector obtained in step 3 of Example 2 was transformed into competent cells of Escherichia coli BL21 strain and the optimal mutant sequence was selected. Proceed as follows:

[0065] 1.

[0066] 1.1 Take 500ul of BL21 bacteria liquid, inoculate it in 50ml of LB liquid medium, cultivate at 37℃, 180r / min for 2-3h until OD600 reaches about 0.5.

[0067] 1.2. Transfer the bacterial solution to a 50ml centrifuge tube and place it on ice for 10 minutes.

[0068] 1. Centrifuge at 4000rpm for 10min at 3 and 4°C to recover the cells.

[0069] 1.4. Discard the culture medium and invert for 1 min.

[0070] 1.5. Add 10ml of pre-cooled 0.1mol / L CaCl to every 50ml of bacteria produced by the bacteria solution 2 , resuspend the cells, and place on ice for 10 min.

[0071] 1.6, 4°C, centrifuge at 4000rpm for 10min to recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com