Epoxy resin anticorrosive coating and preparation method thereof

An anti-corrosion coating and epoxy resin technology, applied in the field of coatings, can solve problems such as personal safety hazards, accidents and personal injuries, and achieve effective anti-corrosion protection, prolong service life, and good shielding protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

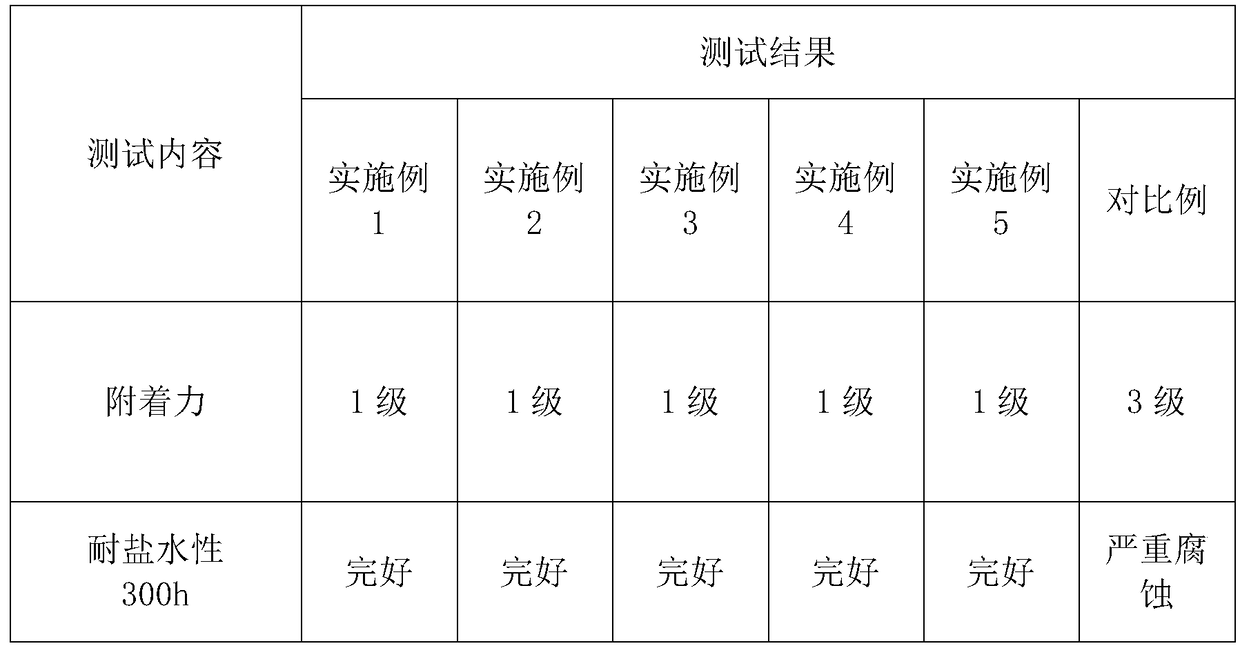

Examples

Embodiment 1

[0023] A kind of epoxy resin anticorrosion coating, by weight, comprises following component:

[0024] 100 parts of water-based epoxy resin emulsion, nano CeO 2 20 parts, 12 parts of zinc phosphate, 15 parts of cellulose acetate butyrate, 4 parts of sodium polyacrylate, 3 parts of sodium silicate, 1 part of silane coupling agent, 3 parts of triethylenetetramine, 2 parts of polyethylene wax, phthalate 1 part of dioctyl diformate, 6 parts of amine antifouling agent, 7 parts of montmorillonite, 1 part of SD-202, 12 parts of phenolic resin, 30 parts of water.

[0025] A preparation method for epoxy resin anticorrosion paint, comprising the following steps:

[0026] (1) Dissolve sodium polyacrylate, sodium silicate, and silane coupling agent in water, stir and mix evenly, heat to 50°C, add nano-CeO 2 After ultrasonic dispersion for 3 hours, add water-based epoxy resin emulsion, stir and disperse at a speed of 700rpm for 1 hour to obtain a mixed solution;

[0027] (2) Add trieth...

Embodiment 2

[0029] A kind of epoxy resin anticorrosion coating, by weight, comprises following component:

[0030] 100 parts of water-based epoxy resin emulsion, nano CeO 2 30 parts, 19 parts of zinc phosphate, 18 parts of cellulose acetate butyrate, 8 parts of sodium polyacrylate, 5 parts of sodium silicate, 2 parts of silane coupling agent, 6 parts of triethylenetetramine, 5 parts of polyethylene wax, phthalate 2 parts of dioctyl diformate, 8 parts of amine antifouling agent, 9 parts of montmorillonite, 3 parts of SD-202, 25 parts of phenolic resin, 40 parts of water.

[0031] A preparation method for epoxy resin anticorrosion paint, comprising the following steps:

[0032] (1) Dissolve sodium polyacrylate, sodium silicate, and silane coupling agent in water, stir and mix evenly, heat to 70°C, add nano-CeO 2 After ultrasonic dispersion for 4 hours, add water-based epoxy resin emulsion, stir and disperse at a speed of 900rpm for 2 hours to obtain a mixed solution;

[0033] (2) Add tr...

Embodiment 3

[0035] A kind of epoxy resin anticorrosion coating, by weight, comprises following component:

[0036] 100 parts of water-based epoxy resin emulsion, nano CeO 2 20 parts, 19 parts of zinc phosphate, 15 parts of cellulose acetate butyrate, 8 parts of sodium polyacrylate, 3 parts of sodium silicate, 2 parts of silane coupling agent, 3 parts of triethylenetetramine, 5 parts of polyethylene wax, phthalate 1 part of dioctyl diformate, 8 parts of amine antifouling agent, 7 parts of montmorillonite, 3 parts of SD-202, 12 parts of phenolic resin, 40 parts of water.

[0037] A preparation method for epoxy resin anticorrosion paint, comprising the following steps:

[0038] (1) Dissolve sodium polyacrylate, sodium silicate, and silane coupling agent in water, stir and mix evenly, heat to 50°C, add nano-CeO 2 After ultrasonic dispersion for 4 hours, add water-based epoxy resin emulsion, stir and disperse at a speed of 700rpm for 2 hours to obtain a mixed solution;

[0039] (2) Add tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com