Silicon nano-material with three-dimensional cross-linked structure as well as preparation method and application thereof

A three-dimensional crosslinking and silicon nanotechnology, applied in nanotechnology, structural parts, chemical instruments and methods, etc., can solve the problems of high synthesis cost and time cost, and achieve the effect of abundant reserves, excellent lithium battery performance and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

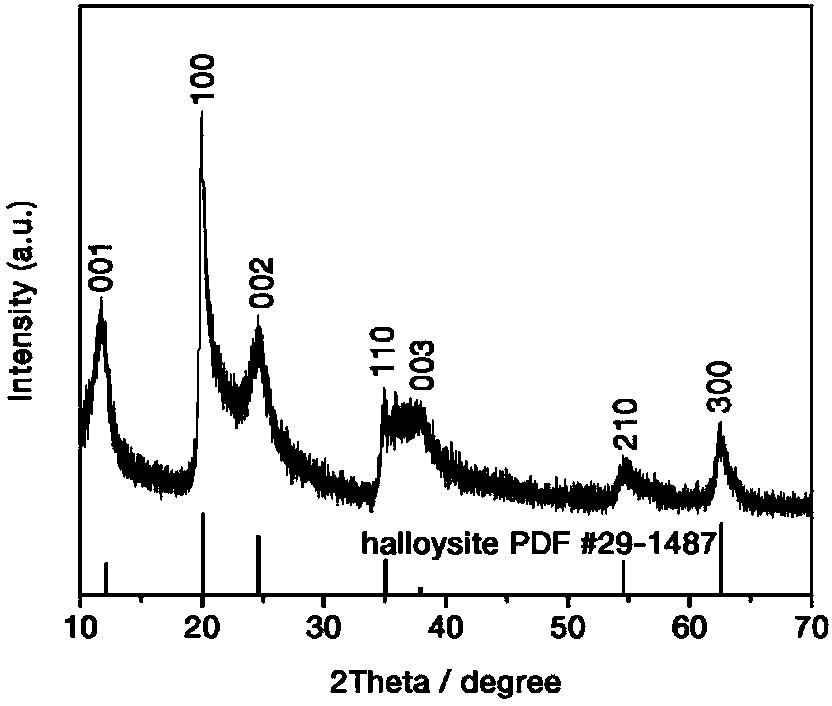

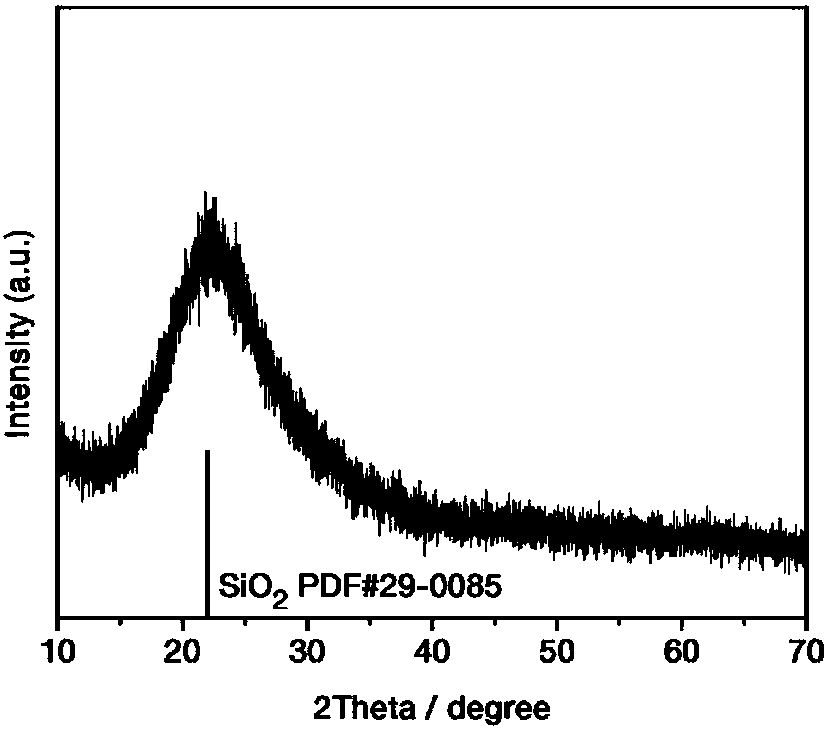

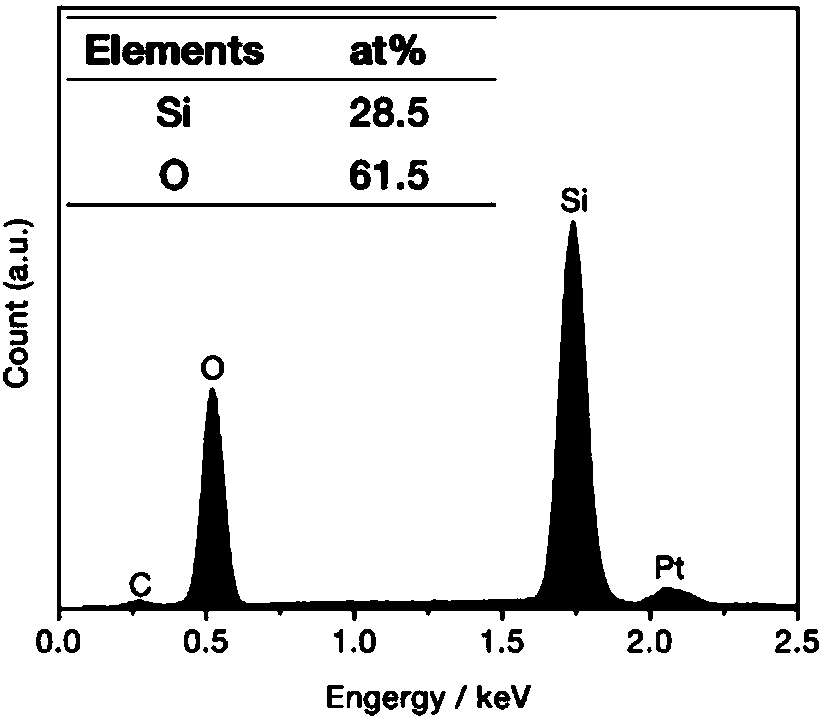

[0034] Weigh 0.5g halloysite clay mineral and disperse it into 2mol / L hydrochloric acid solution (40mL), stir evenly, transfer it to a reaction kettle, seal it, and place it at 120°C for 4h. After the reaction product was centrifuged, washed and dried at 60°C for 6-8 hours, 0.2g of the product, 0.8g of magnesium powder, and 8g of aluminum chloride powder were weighed and mixed evenly, then transferred to a reaction kettle and placed at 250°C for 10 hours. The reaction product was purified by acid washing with a mixture of hydrochloric acid (2mol / L) and hydrofluoric acid (10wt%) at 80°C (volume ratio 2:1) for 3h, dried and dried at 60°C for 6-8h to obtain a powder sample, And the prepared samples were tested for lithium battery performance. like figure 1 The shown halloysite clay mineral is identified as a high-purity halloysite phase by XRD; as figure 2 The powder product obtained by the shown hydrothermal acid treatment is amorphous silicon dioxide; it is analyzed by X-ray...

Embodiment 2

[0036] Weigh 0.7g of halloysite clay mineral and disperse it into 5mol / L hydrochloric acid solution (40mL), stir evenly, transfer it to a reaction kettle, seal it, and place it at 130°C for 2h. After the reaction product was centrifuged, washed and dried at 60°C for 6-8 hours, 0.2g of the product, 0.8g of magnesium powder, and 8g of aluminum chloride powder were weighed and mixed evenly, then transferred to a reaction kettle and placed at 250°C for 10 hours. The reaction product was purified by acid washing with a mixture of hydrochloric acid (2mol / L) and hydrofluoric acid (10wt%) at 80°C (volume ratio 2:1) for 3h, dried and dried at 60°C for 6-8h to obtain a powder sample, And the prepared sample was tested for lithium battery performance, and it was found that the performance was equivalent to that of the material prepared in Example 1.

Embodiment 3

[0038] Weigh 0.7g montmorillonite and disperse it into 2mol / L sulfuric acid solution (40mL), stir evenly, transfer to a reaction kettle, seal it, and place it at 90°C for 2h. After the reaction product was centrifuged, washed and dried at 60°C for 6-8 hours, 0.2g of the product, 0.8g of magnesium powder, and 8g of aluminum chloride powder were weighed and mixed evenly, then transferred to a reaction kettle and placed at 210°C for 4 hours. The reaction product was purified by acid washing with a mixture of hydrochloric acid (2mol / L) and hydrofluoric acid (10wt%) at 80°C (volume ratio 2:1) for 3h, dried and dried at 60°C for 6-8h to obtain a powder sample, And the prepared samples were tested for lithium battery performance. It is found that the material prepared in this example is slightly inferior to the material prepared in Example 1 in terms of purity, size and performance, but it is also significantly better than the general lithium battery negative electrode active materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com