Production method of composite film

A composite film and cast film technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., to reduce production costs, save winding and unwinding equipment and transportation links, and prevent secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

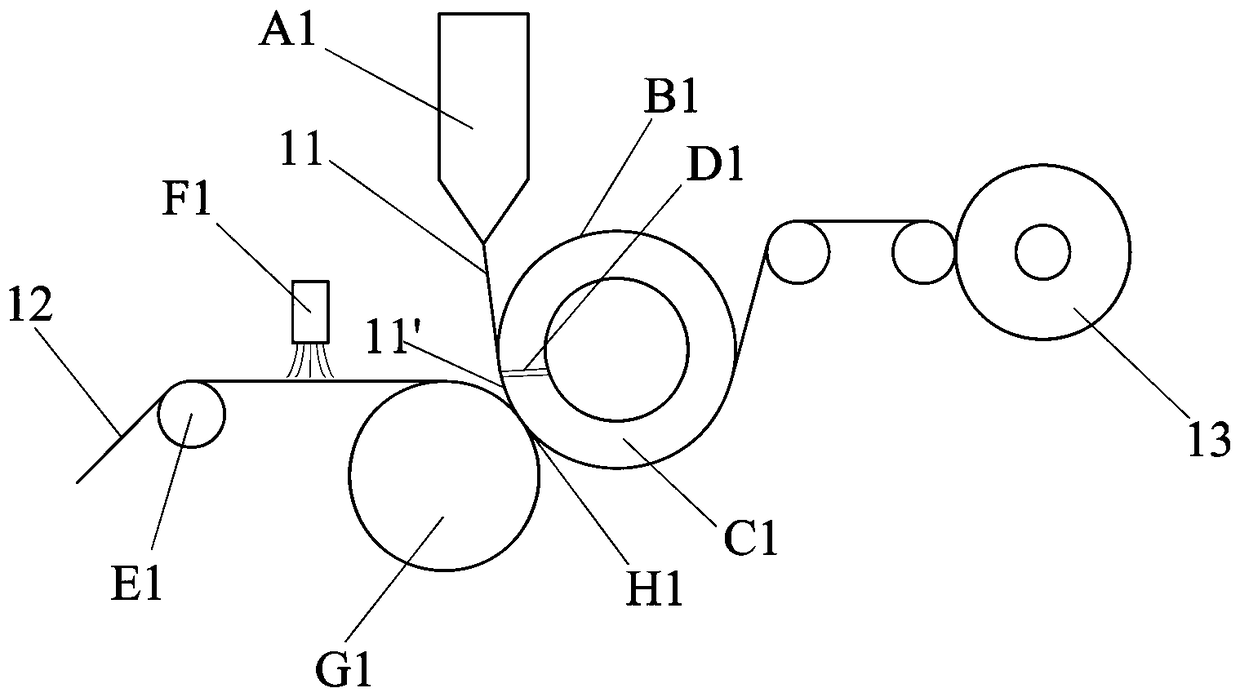

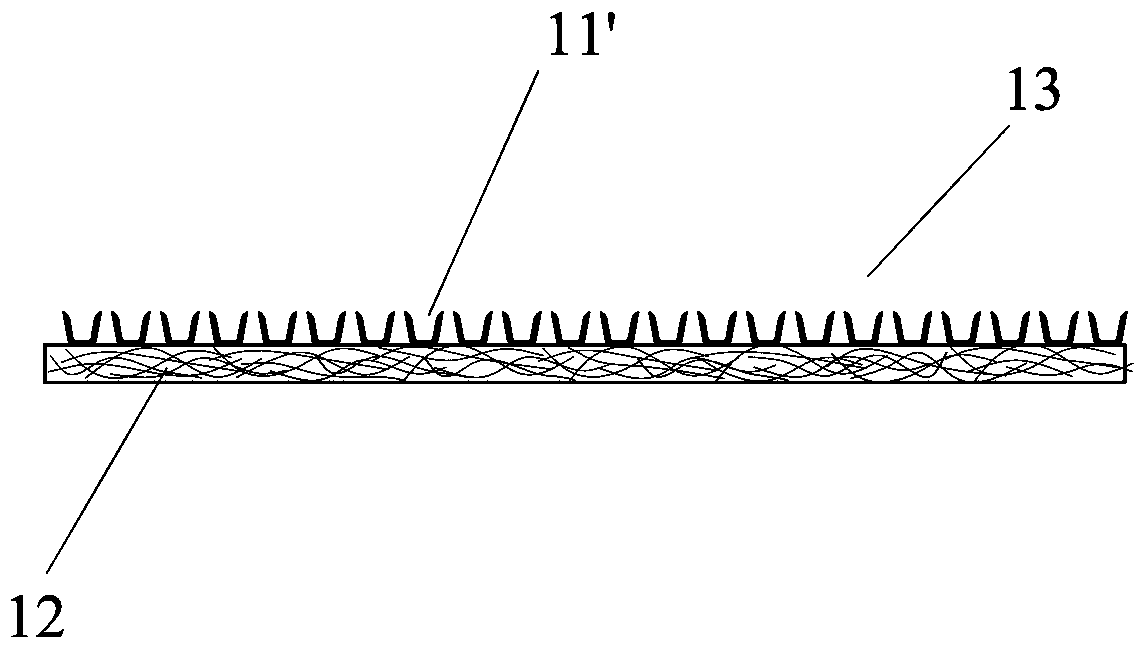

[0029] Such as figure 1 , figure 2 As shown, 45% LDPE 100AC, 45% LLDPE 7050 and 10% functional masterbatch are used as raw materials. During production, the above mixture is melted and extruded by screw extruder A1 to form cast film 11; the formed cast film 11 is drawn To the forming net cage B1, the forming net cage B1 is nested on the forming drum C1. At the vacuum suction port D1 of the forming drum C1, due to the action of the vacuum pump connected to the forming drum C1, the forming drum C1 A negative pressure is formed, so that the casting film 11 on the forming cage B1 at the vacuum suction port D1 forms a small-porous porous film 11', wherein: the temperature of the casting film at the entrance of the vacuum suction port is 150°C, and the vacuum degree in the vacuum suction port area It is 0.05MPa, the forming net cage has 248 holes per square centimeter, and the area of the single small hole is 1.5mm 2 ; The non-woven fabric 12 is glued through the guide roller E1 th...

Embodiment 2

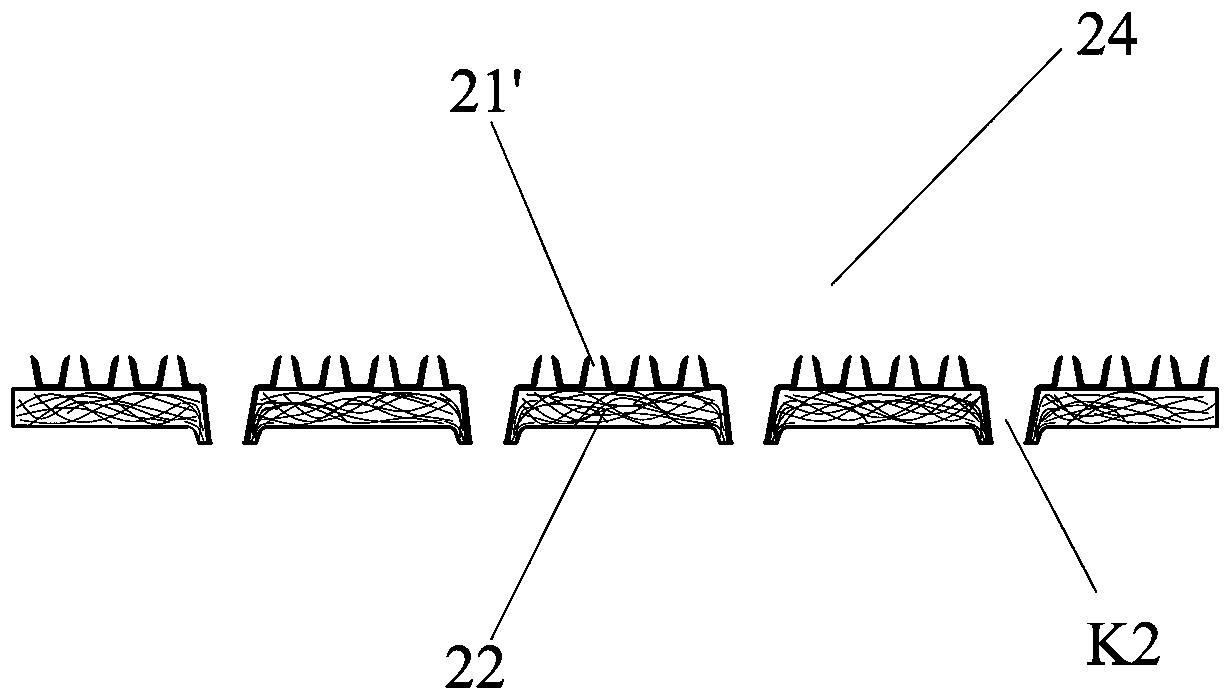

[0041] Such as Figure 4 , Figure 5 As shown, using 20% LDPE 3527, 80% LLDPE 7050 and 10% functional masterbatch as raw materials, during production, the above mixture is melted and extruded by screw extruder A2 to form cast film 2; the formed cast film 2 is drawn To the forming net cage B2, the forming net cage B2 is nested on the forming drum C2. At the vacuum suction port D2 of the forming drum C2, due to the action of the vacuum pump connected to the forming drum C2, the forming drum C2 Negative pressure is formed so that the cast film 21 on the forming cage B2 at the vacuum suction port D2 forms a small-porous porous film 21', where: the temperature of the cast film at the entrance of the vacuum suction port is 180°C, and the vacuum degree in the vacuum suction port area It is 0.08MPa, the forming net cage has 480 holes per square centimeter, and the area of the single small hole is 0.1mm 2 The non-woven fabric 22 is glued through the guide roller E2 through the gluing...

Embodiment 3

[0044] Such as Image 6 , Figure 7 As shown, 40% LDPE 3527, 50% LLDPE 7050 and 10% functional masterbatch are used as raw materials. During production, the above mixture is melted and extruded by screw extruder A3 to form a cast film 31; the formed cast film 31 is drawn To the forming net cage B3, the forming net cage B3 is nested on the forming drum C3. At the vacuum suction port D3 of the forming drum C3, due to the action of the vacuum pump connected to the forming drum C3, the forming drum C3 A negative pressure is formed, so that the casting film 31 on the forming cage B3 at the vacuum suction port D3 forms a small-porous porous film 31', wherein: the temperature of the casting film at the entrance of the vacuum suction port is 160°C, and the vacuum degree of the vacuum suction port area Is 0.1MPa, the forming net cage has 1256 holes per square centimeter, and the area of the single small hole is 0.05mm 2 The non-woven fabric 32 is glued through the guide roller E3 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com