Stereo hot air non-woven fabric production method

A technology of hot air non-woven fabric, production method, applied in the direction of non-woven fabric, textile and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

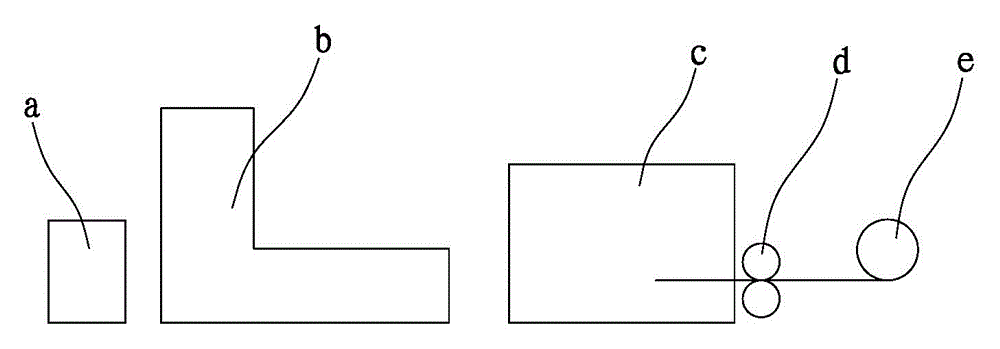

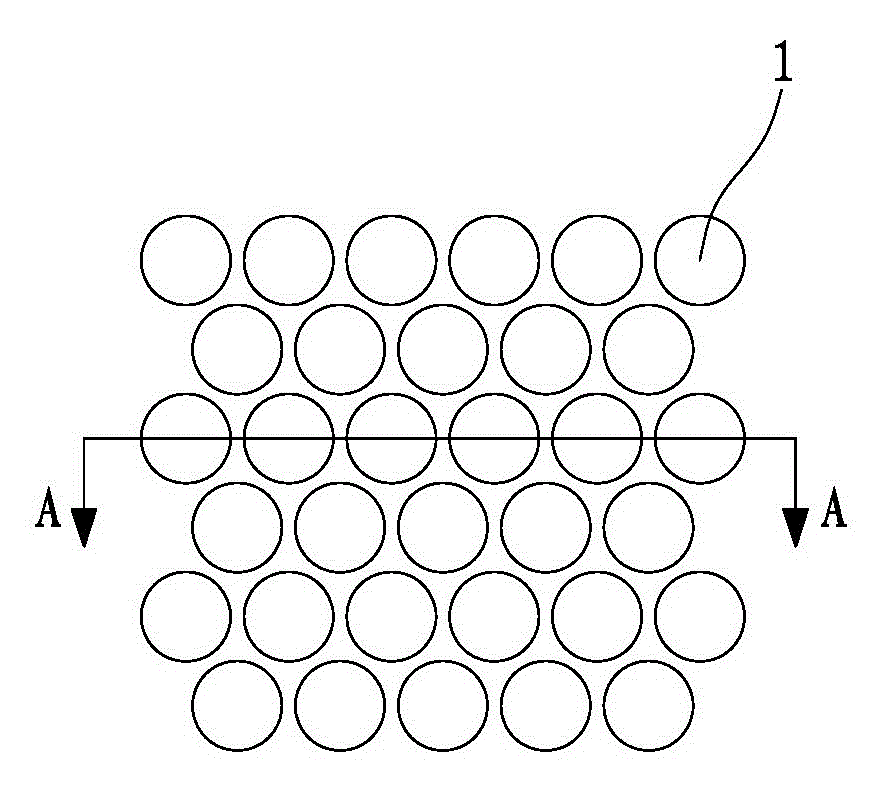

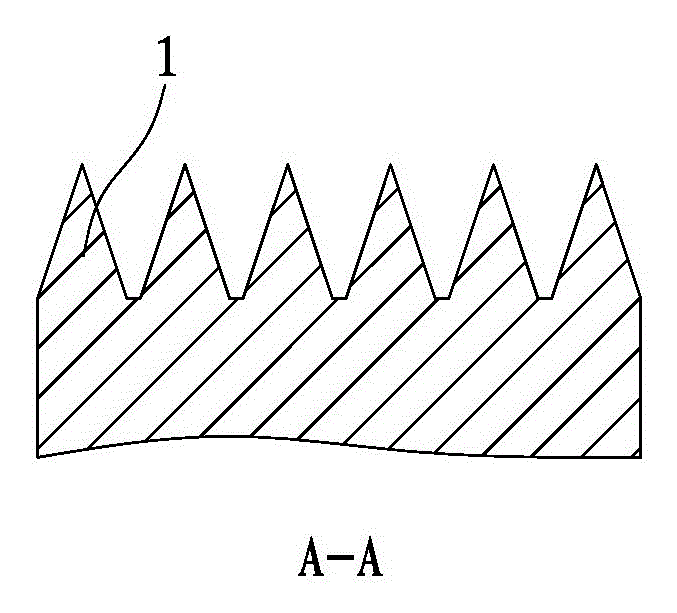

[0042] Cooperate figure 1 , Figure 2A and Figure 2B As shown, take 1.5dtex*38mm PE / PP bicomponent fiber as raw material. During production, the fiber is unpacked and loosened by the bale opener and then sent to the carding machine, carded into a fiber web and entered into the oven. The temperature of the hot air is 145°C, and the frequency of the hot air blower is 38Hz for penetrating heating. The surface of the fiber is The PE begins to soften and melt, and several bonding points are formed between the fibers. At the same time, due to capillary penetration, the molten PE flows to the core layer PP and bonds with it to form a certain cohesive force, thus giving the fiber web a certain strength. The consolidated fiber web is three-dimensionally formed by a pair of heated meshing convex rollers and concave rollers to form a three-dimensional perforated non-woven fabric, wherein the protrusions of the convex rollers are needles 1, and the root area of a single needle is 3.1...

Embodiment 2

[0045] Cooperate Figure 3A , Figure 3B and Figure 5 As shown, take 2.0dtex*38mm PE / PET bicomponent fiber as raw material. During production, the fibers are unpacked and loosened by the bale opener and then sent to the carding machine, carded into a fiber web and entered into the oven. The temperature of the hot air is 150°C, and the frequency of the hot air blower is 45Hz for penetration heating. The PE begins to soften and melt, and a number of bonding points are formed between the fibers. The consolidated fiber web is subjected to three-dimensional molding processing by a pair of heated meshing convex rollers and concave rollers to form a three-dimensional perforated non-woven fabric. is a bump, the root area of a single bump is 8.0mm 2 , the bump height is 2.5mm, and the convex roller and the concave roller are close to the ironing equipment. The temperature reaches 70°C when three-dimensionally forming the convex roll. Finally, the non-woven fabric is cooled and ...

Embodiment 3

[0048] Cooperate Figure 4A , Figure 4B and Figure 6 As shown, take 1.5dtex*38mm PE / PP and 2.2dtex*38mm PE / PET bicomponent fibers as raw materials. During production, the two kinds of fibers are respectively unpacked and loosened by the unpacking machine and sent to the corresponding carding machine. The 1.5dtex*38mm PE / PP fiber web is used as the surface layer, and the 2.2dtex*38mm PE / PET fiber web is used as the bottom layer. The two layers of fiber webs are superimposed and sent to the oven. The temperature of the hot air is 140°C and the frequency of the hot air fan is 45 Hz for penetrating heating. The consolidated fiber webs are preheated in the preheating equipment g. The temperature of the oven is 130°C, and then a pair of heated meshing convex rolls and concave rolls are used for three-dimensional molding to form a three-dimensional hot-air non-woven fabric. Root area is 7.0mm 2 , the bump height is 2.4mm, and the root area of a single needle is 2.0mm 2 , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com