A production method of an apertured film and a vacuum punching device thereof

A production method and film technology, applied in the field of perforated film production and its vacuum punching device, can solve the problem of low energy consumption, save energy consumption, save winding equipment, unwinding equipment and transportation links, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

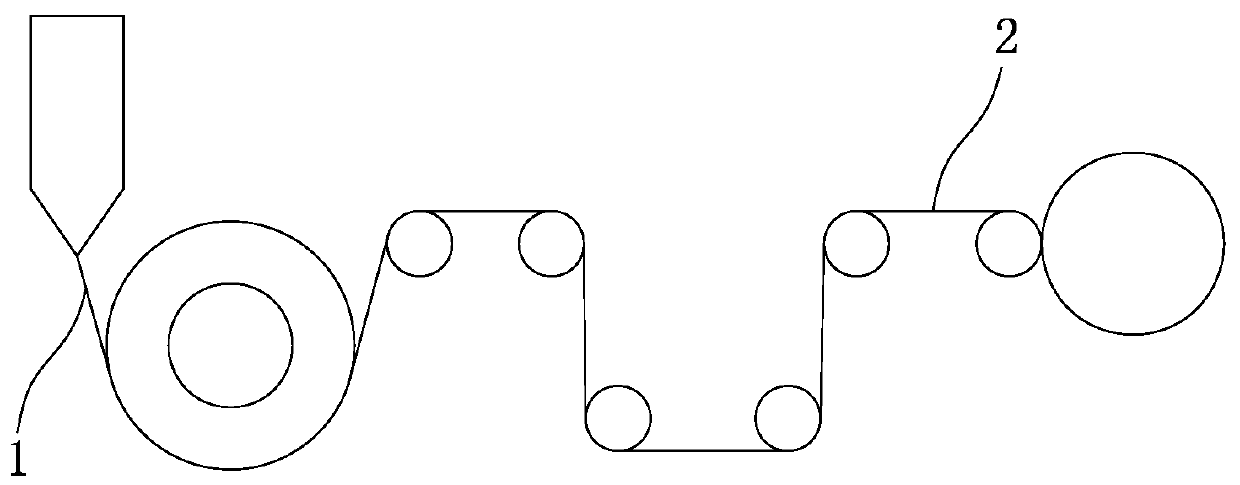

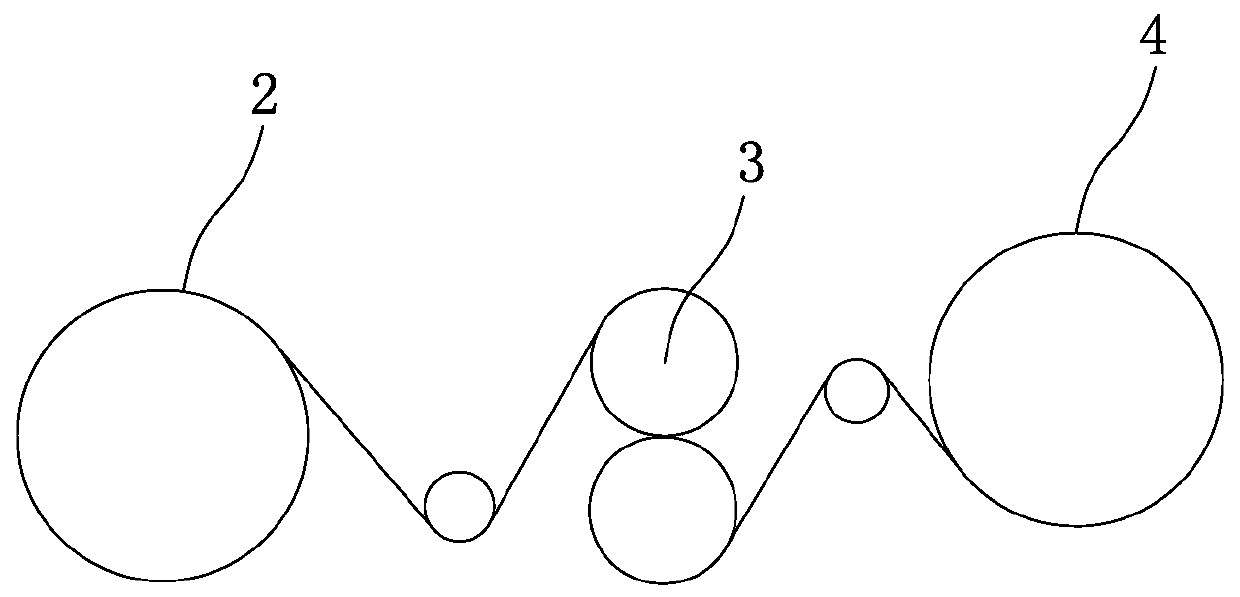

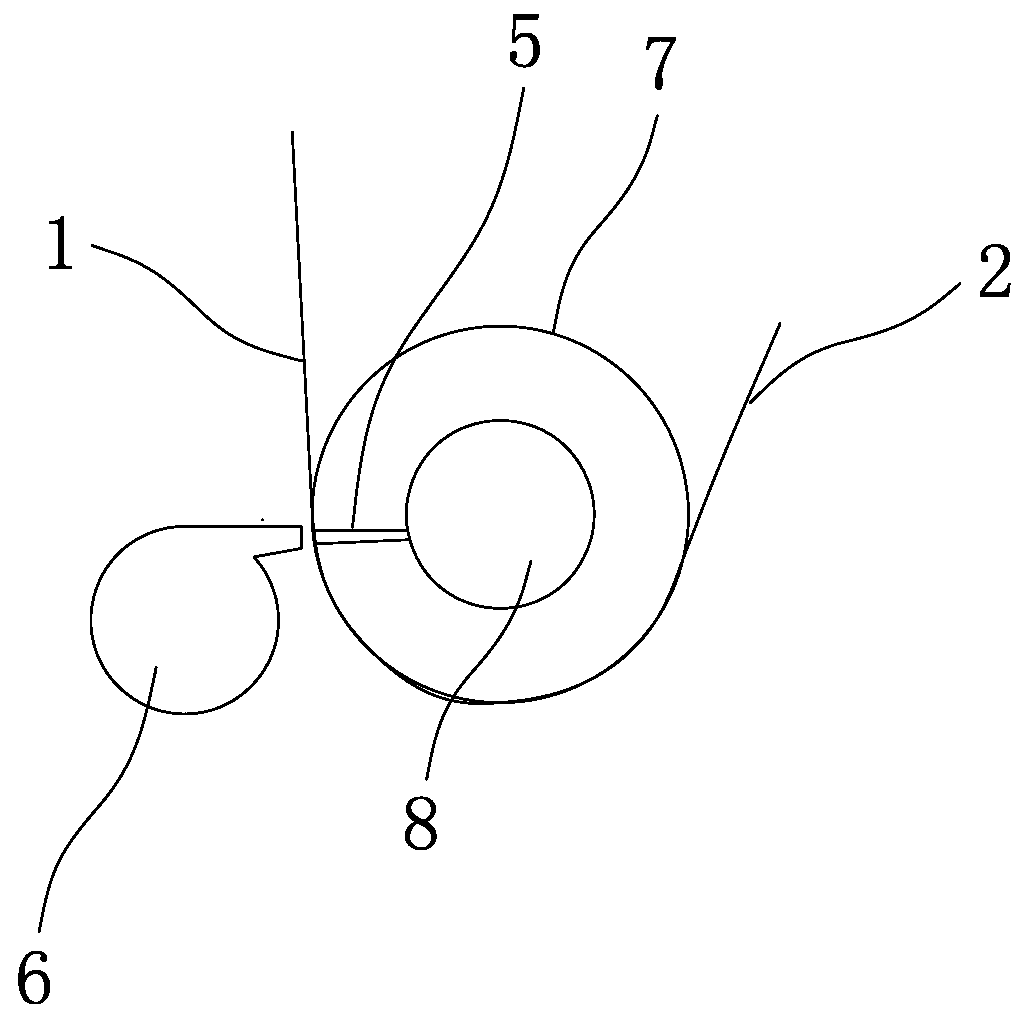

[0030] Cooperate image 3 and Figure 4 As shown, using 35% LDPE 100AC, 55% LLDPE 7050 and 10% functional masterbatch as raw materials, during production, it is extruded through a single-screw extruder to form a cast film 1. Entering the vacuum punching device, in the vacuum suction area 5 of the vacuum forming drum 8, due to the effect of the internal and external pressure difference, a perforated film 2 with small holes 9 is formed. When the temperature of the cast film reaches 110°C, the temperature of the extrusion die can be controlled to make the cast film reach the required temperature, and the vacuum degree can be adjusted to 0.05MPa by adjusting the speed of the vacuum pump. On the other hand, the ultrasonic atomizing device 6 located directly opposite the vacuum suction area 5 of the vacuum forming drum 8, the atomized moisture makes the humidity of the air sucked by the vacuum suction area 5 reach 70%, so that when the moisture in the air adheres to the open air wi...

Embodiment 2

[0040] Cooperate Figure 5 and Image 6 As shown, using 25% LDPE 100AC, 65% LLDPE 9500 and 10% functional masterbatch as raw materials, during production, it is extruded through a single-screw extruder to form a cast film 1. The casting film 1 enters the vacuum punching equipment at high temperature for vacuum punching to form an apertured film 2 with small holes 9. At this time, the temperature of the casting film during vacuum punching is detected by an infrared thermal imager FLUKE Ti110-9HZ. At 115°C, the temperature of the extrusion die can be controlled to make the cast film reach the required temperature, and the vacuum degree can be adjusted to 0.08MPa by adjusting the speed of the vacuum pump. The ultrasonic atomizing device 6 located directly opposite the vacuum suction area 5 of the vacuum forming drum 8 makes the atomized moisture adhere to the high-temperature perforated film 2 after the film is perforated, and will be taken away due to the effect of evaporative ...

Embodiment 3

[0042] Cooperate Figure 7 and Figure 8 As shown, using 20% LDPE 100AC, 65% LLDPE 9500 and 15% functional masterbatch as raw materials, during production, it is extruded through a single-screw extruder to form a cast film 1. The casting film 1 enters the vacuum punching equipment at high temperature for vacuum punching to form an apertured film 2 with small holes 9. At this time, the temperature of the casting film during vacuum punching is detected by an infrared thermal imager FLUKE Ti110-9HZ. At 112°C, the temperature of the extrusion die can be controlled to make the cast film reach the required temperature, and the vacuum degree can be adjusted to 0.05MPa by adjusting the rotation speed of the vacuum pump. The ultrasonic atomizing device 6 located directly opposite the vacuum suction area 5 of the vacuum forming drum 8 makes the atomized moisture adhere to the high-temperature perforated film 2 after the film is perforated, and will be taken away due to the evaporativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com