Method of preparing tungsten-doped superfine yttrium oxide compound powder by freeze drying

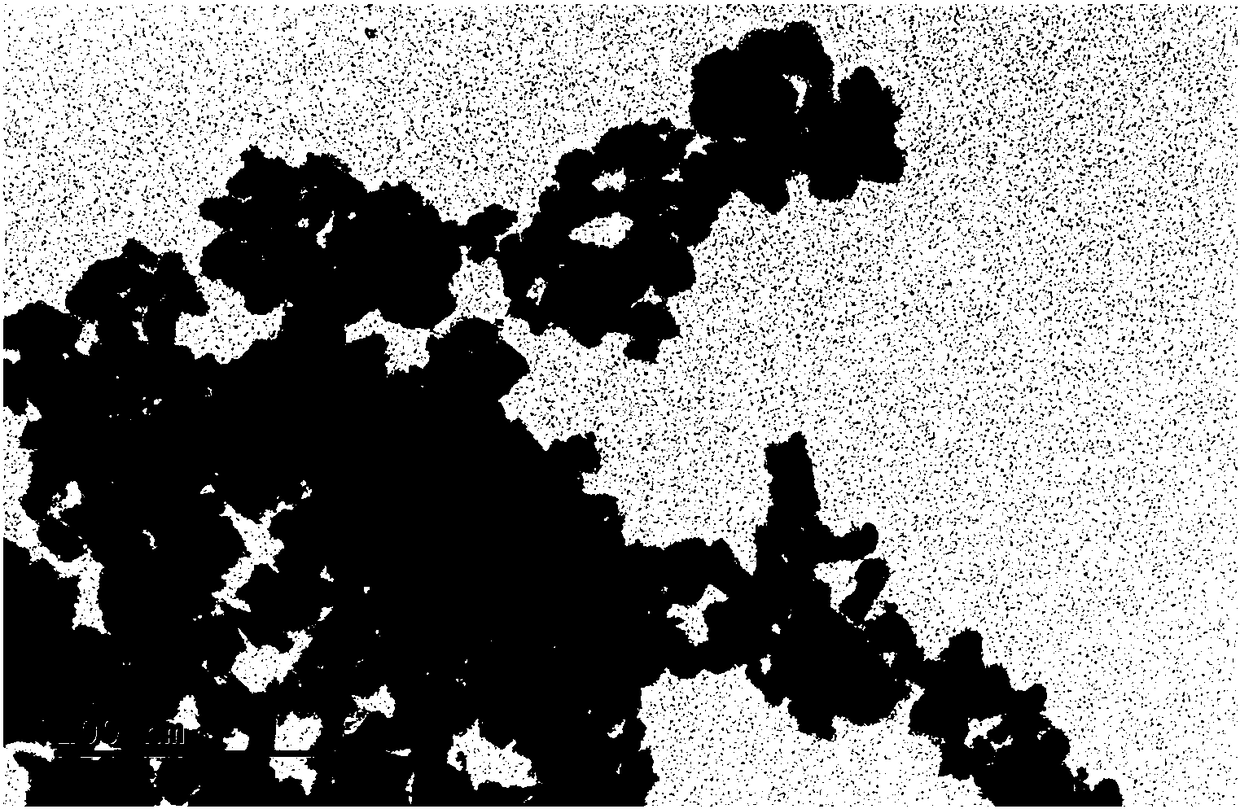

A technology of composite powder and yttrium oxide, which is applied in the field of preparing ultrafine W-Y2O3 composite powder, can solve the problems of large crystal grains, uneven structure, uniform doping, etc., and achieve improved particle agglomeration, narrow particle size distribution, and dispersibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolve 2 g of AMT and 0.1332 g of yttrium nitrate hexahydrate in 100 mL of deionized water (the concentration of AMT is 0.02 g / mL, the mass of yttrium nitrate hexahydrate is 6.66% of the mass of ammonium metatungstate), and ultrasonically treated (ultrasonic treatment power is 100W, ultrasonic time is 1h) and the solution is obtained after fully dissolving and dispersing;

[0036] (2) Pour 50ml of the solution into a watch glass, pre-freeze at -40°C for 8 hours;

[0037] (3) After the temperature of the freeze dryer is lowered to the freezing temperature of -58°C and stabilized, put the pre-frozen watch glass into the freeze dryer, turn on the vacuum pump, maintain the vacuum degree of 1.3Pa, and freeze dry for 12h;

[0038] (4) calcining the freeze-dried powder in an argon gas stream at 450°C for 0.5 h to obtain composite oxide powder;

[0039] (5) The composite oxide powder is subjected to two-step reduction in a hydrogen stream (600° C. for 1.5 hours, and 700°...

Embodiment 2

[0042] (1) Dissolve 10 g of AMT and 0.666 g of yttrium nitrate hexahydrate in 100 mL of deionized water (the concentration of AMT is 0.1 g / mL, the mass of yttrium nitrate hexahydrate is 6.66% of the mass of ammonium metatungstate), and ultrasonically treated (The ultrasonic treatment power is 400W, and the ultrasonic time is 0.5h) to obtain the solution after fully dissolving and dispersing;

[0043] (2) Pour 50ml solution into a watch glass, pre-freeze at -40°C for 24h;

[0044] (3) After the temperature of the freeze dryer is lowered to the freezing temperature of -50°C and stabilized, put the pre-frozen watch glass into the freeze dryer, turn on the vacuum pump, maintain the vacuum degree of 13Pa, and freeze dry for 24h;

[0045] (4) calcining the freeze-dried powder in argon gas flow at 450°C for 1 h to obtain composite oxide powder;

[0046] (5) The composite oxide powder is subjected to a two-step reduction in a hydrogen stream (at 550° C. for 2 hours, and at 700° C. fo...

Embodiment 3

[0049] (1) Dissolve 10 g of AMT and 0.666 g of yttrium nitrate hexahydrate in 100 mL of deionized water (the concentration of AMT is 0.1 g / mL, the mass of yttrium nitrate hexahydrate is 6.66% of the mass of ammonium metatungstate), and ultrasonically treated (The ultrasonic treatment power is 200W, and the ultrasonic time is 0.5h) to obtain the solution after fully dissolving and dispersing;

[0050] (2) Pour 50ml solution into a watch glass, pre-freeze at -20°C for 18h;

[0051] (3) After the temperature of the freeze dryer is lowered to the freezing temperature of -50°C and stabilized, put the pre-frozen watch glass into the freeze dryer, turn on the vacuum pump, maintain the vacuum degree of 4.5Pa, and freeze dry for 24h;

[0052] (4) calcining the freeze-dried powder in an argon gas stream at 450°C for 0.5 h to obtain composite oxide powder;

[0053] (5) The composite oxide powder is subjected to two-step reduction (600° C. for 3 hours, and 800° C. for 1.5 hours) in a hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com