Dolomite limestone-iron oxide-nano chitosan composite material based on mantou formation mineral rocks and preparation and application thereof

A technology of dolomitic limestone and nano-chitosan, which is applied to water pollutants, other chemical processes, chemical instruments and methods, etc. problem, to achieve the effect of good adsorption and removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation process and method of dolomitic limestone-iron oxide-nano chitosan composite material, the main steps of implementation are:

[0034](1) Pretreatment of dolomitic limestone (drying and crushing): dry the natural dolomitic limestone at 105°C to constant weight; mechanically crush the dried dolomitic limestone, and the crushing time is 1 ~3min, crushed and sieved to obtain dolomitic limestone powder material with particle size less than 0.5μm;

[0035] (2) Preparation of nano-chitosan: 1 g of chitosan was dissolved in 2 L of acetic acid with a concentration of 2% (v / v), and 1 L of sodium tripolyphosphate solution with a concentration of 0.75 mg / mL was added and stirred slowly. At this time, it can be seen that the solution is divided into three layers, and the top and bottom are respectively: supernatant, polymer and milky white suspension. Take out the milky white suspension and soak it in double distilled water for 1 to 3 hours, and air dry it for later ...

Embodiment 2

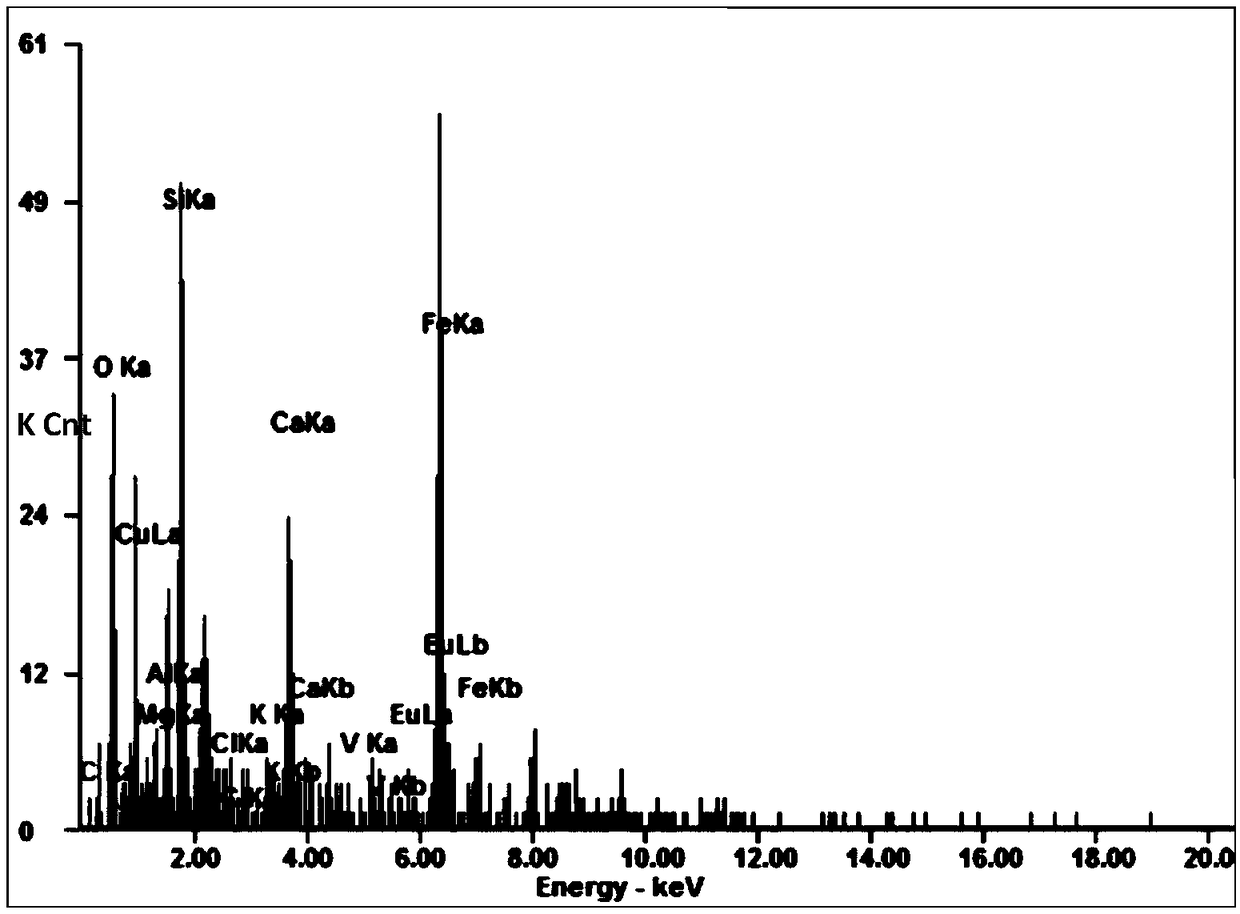

[0039] Investigate the main components of the dolomitic limestone-iron oxide-nano chitosan composite material involved in embodiment 1 and the physicochemical properties of the main component dolomitic limestone, as shown in table 1, carbonate minerals in the dolomitic limestone It is the main component (51.2%), of which dolomite accounts for 26.3%. According to the content of dolomite between 25% and 50%, this mineral rock material can be identified as dolomitic limestone. From the scanning electron microscope spectrum of the composite material (Figure 2), it can be seen that the surface of this material is irregular, the overall structure is block-like, and the specific surface area is large, which is conducive to the adsorption of heavy metal ions. The X-ray energy spectrum of the composite material is shown in image 3 As shown, the main constituent elements of the composite material are Si, Ca, Mg, Fe, Al, K, Na, O, C, and N. A large amount of Fe elements may partly come...

Embodiment 3

[0043] Investigate the adsorption and removal capacity of the dolomitic limestone-iron oxide-nano chitosan composite material involved in the invention embodiment 1 to cadmium, lead and nickel in a single metal system, the adsorption condition is: get 10mg composite material and place it in 100mL The initial concentration is 1-200mg / L in a single heavy metal solution system, after shaking in a constant temperature shaker at 25°C and 180r / min for 12h, measure the heavy metal content in the wastewater after adsorption, and use the following formula to calculate the adsorption capacity of the composite material for heavy metals And evaluate the heavy metal adsorption capacity of this composite material.

[0044] The formula for calculating the adsorption capacity is:

[0045] where c 1 、c 2 is the content (mg / L) of heavy metal cadmium, lead and nickel ions before and after adsorption in monometallic wastewater, v is the volume of heavy metal solution (L), m is the mass of ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com