Preparation method and application of foamed three-dimensional graphene oxide

A three-dimensional, foam-like technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as danger, achieve fast removal speed, excellent saturated adsorption capacity, and wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

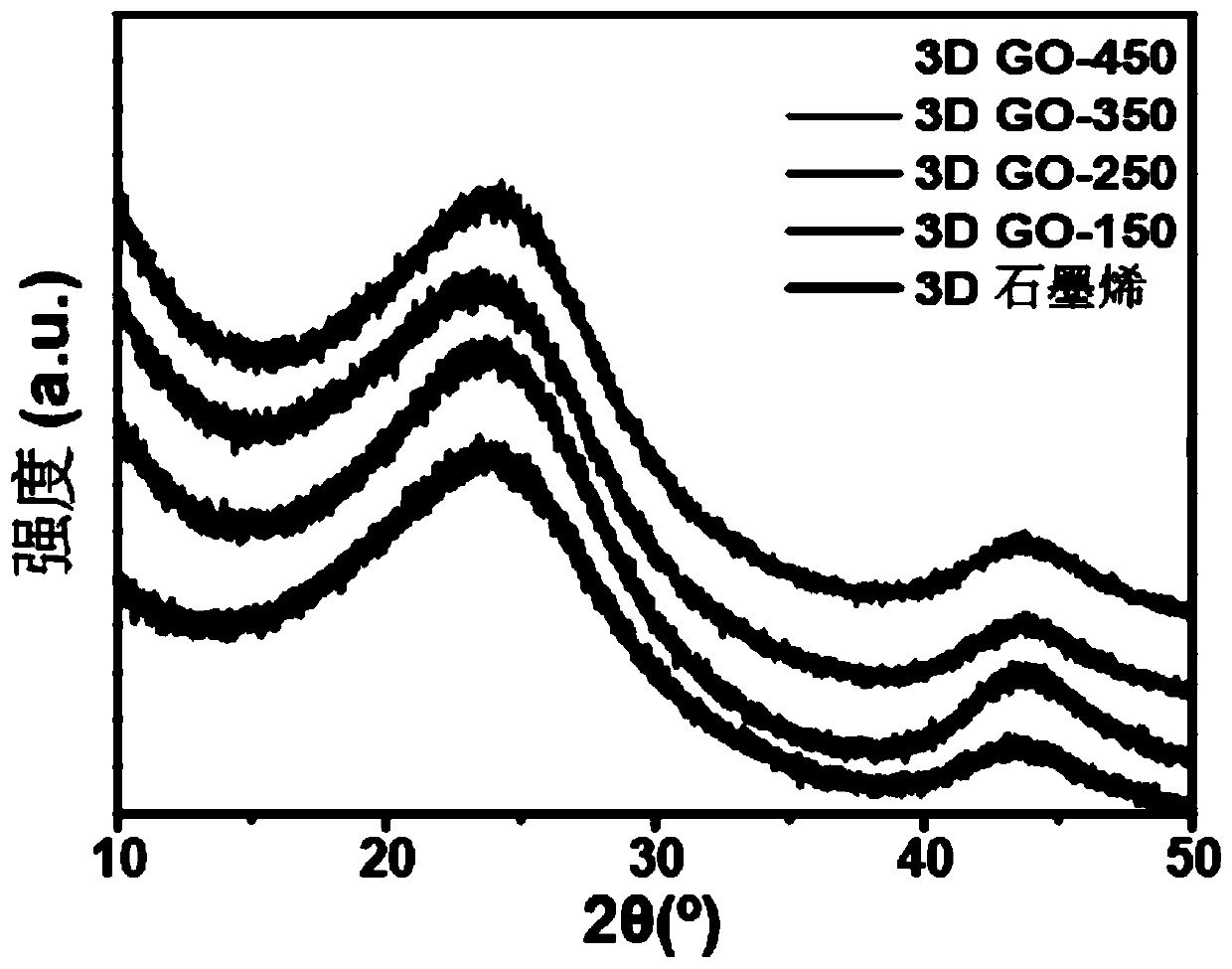

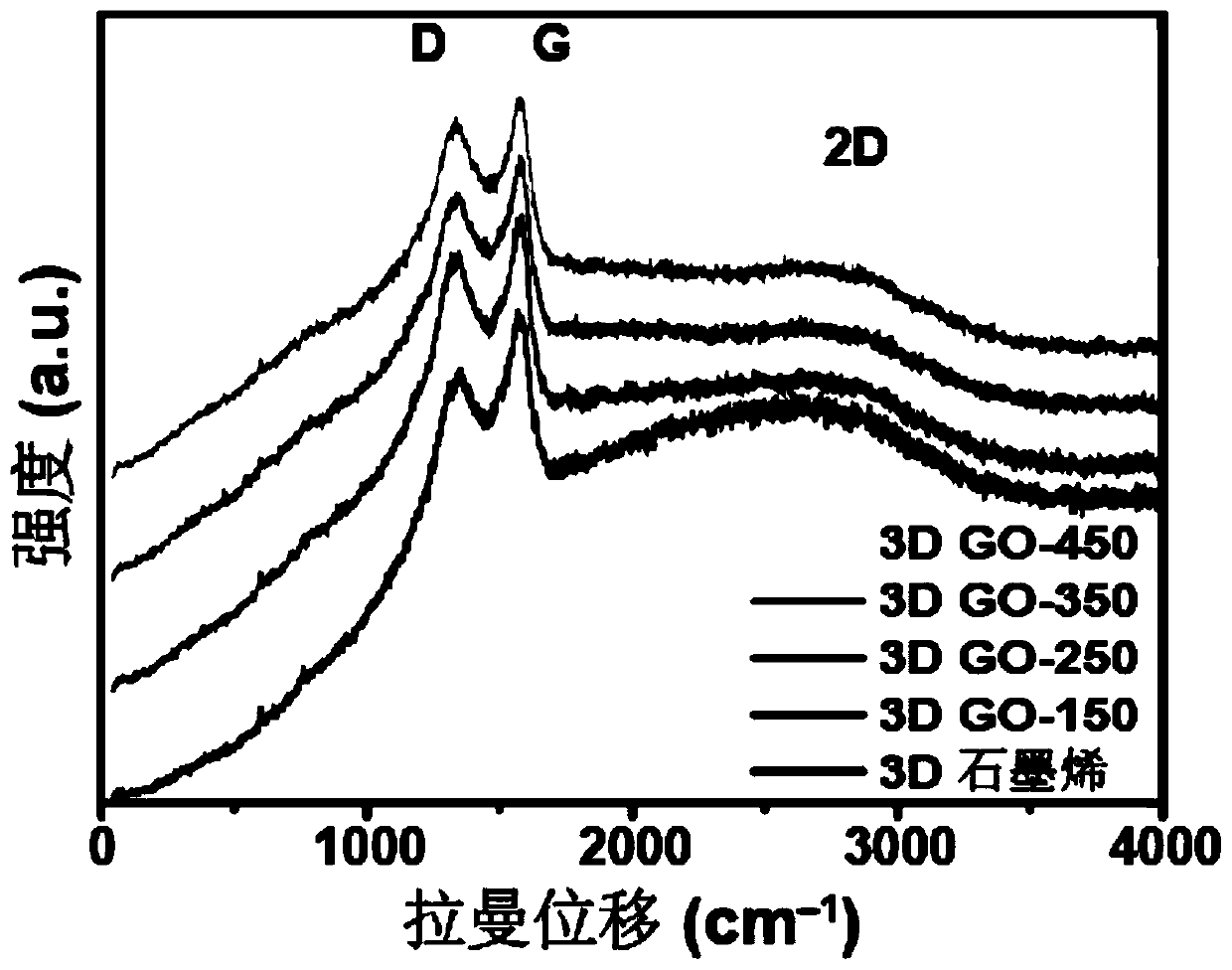

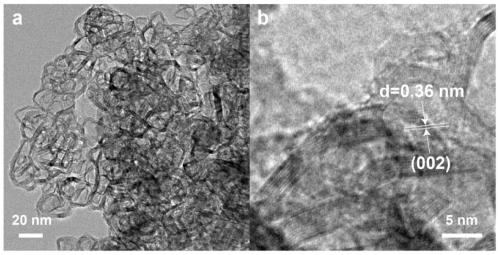

[0036] Prepare foamy three-dimensional graphene oxide according to the following steps:

[0037] (1) with glucose (C 6 h 12 o 6 ) as carbon source, supplemented with ammonium chloride (NH 4 Cl) is the foaming agent, and the glucose and the foaming agent ammonium chloride are fully ground and mixed in an agate mortar according to the mass ratio of 1:1, and the temperature is raised to 250°C at 4°C / min under an inert atmosphere and kept for 1 hour , and then continue to heat up to 900°C and keep at 900°C for 6 hours, and naturally cool to room temperature to obtain a foamy black three-dimensional graphene precursor, marked as 3D graphene;

[0038](2) After the black three-dimensional three-dimensional graphene precursor obtained in step (1) is moderately ground, it is placed in the air, and after secondary calcination at a temperature of 150 ° C for 6 hours, foamy three-dimensional three-dimensional graphene oxide is obtained, which is marked as 3D GO-150.

Embodiment 2

[0040] The difference from Example 1 is that the temperature in step (2) is 250°C; the resulting foamy three-dimensional graphene oxide is marked as 3D GO-250.

Embodiment 3

[0042] The difference from Example 1 is that the temperature in step (2) is 350°C; the resulting foamy three-dimensional graphene oxide is marked as 3D GO-350.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com