Spinning and drafting integrated preparation device and method forhigh-performance micro-nano fiber yarn

A technology of micro-nano fiber and preparation device, applied in drafting equipment, spinning machine, open-end spinning machine, etc., can solve the problems of inability to meet, inability to meet practical application requirements, low fiber orientation, low crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

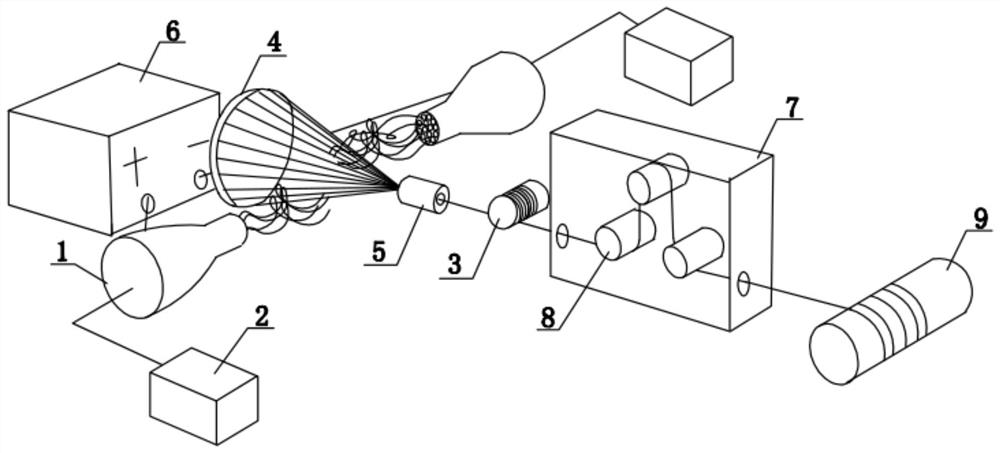

[0032] An integrated high-performance micro-nano fiber yarn preparation device for spinning and drafting, including a spinning unit, a yarn forming unit for spinning and twisting the spinning of the spinning unit into a primary yarn, and a primary yarn for spinning the spinning unit Thermal drawing unit for heating and drawing yarn.

[0033] The spinning unit includes two corresponding spray heads 1 and a liquid supply tank 2 for supplying spinning liquid to the spray heads 1 . It can ensure the continuous supply of spinning liquid and realize the continuous spinning process; the use of double nozzles can significantly increase the spinning output.

[0034] The distance between the two nozzles 1 is 3 cm to 200 cm, and the nozzle 1 is a needle nozzle or a needle-free nozzle; the needle nozzle is a single-needle or multi-needle combination typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com