Method for fast and non-destructive differentiation of polyamide products

A polyamide and product technology, which is applied in the field of physical evidence identification, can solve the problems of small peak strength of fingerprint spectrum, insufficient crystallinity of polyamide products, poor response, etc., and achieve the effect of simple operation and rich fiber identification methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

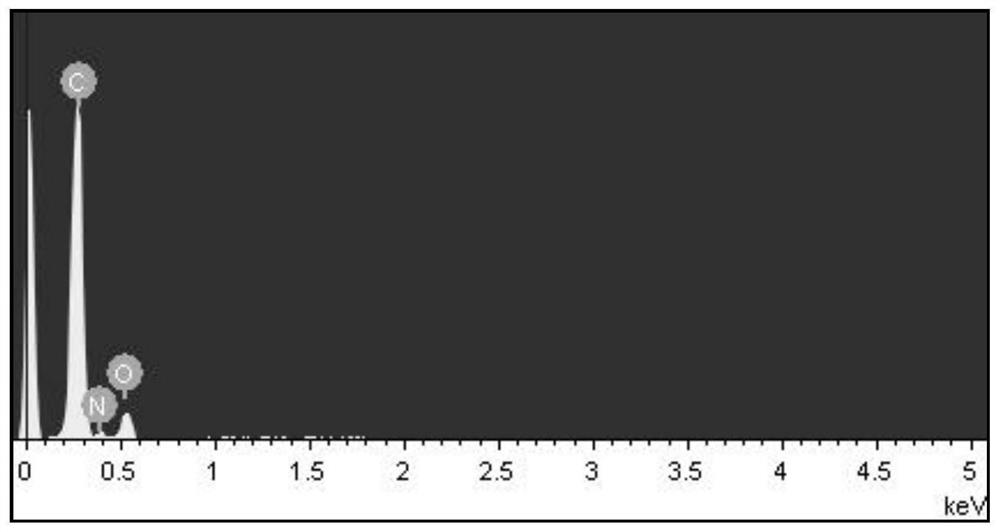

[0062] Place the sample 1 on the sample stage of the electron microscope, wait for the electron microscope to be vacuumed, apply a voltage of 20KV, and work at a distance of 10mm. Select a point with a flat surface and magnify it by 30 times for analysis. Record the elemental composition of the sample, the results are as figure 1 and as shown in Table 2, figure 1 Among them, the ordinate is the intensity of the peak, and the more the element content, the higher the peak. Table 2 shows the weight percentage and atomic percentage of C, N, and O elements quantitatively analyzed by the energy spectrometer.

[0063] Table 2 Elemental composition of sample 1

[0064] element weight percentage atomic percent C 64.25 69.32 N 14.94 13.82 O 20.81 16.85 Total 100.00

[0065] The same method was used to analyze and repeat the test five times, and the specific elemental composition of the samples was averaged to calculate the average percentage...

Embodiment 2

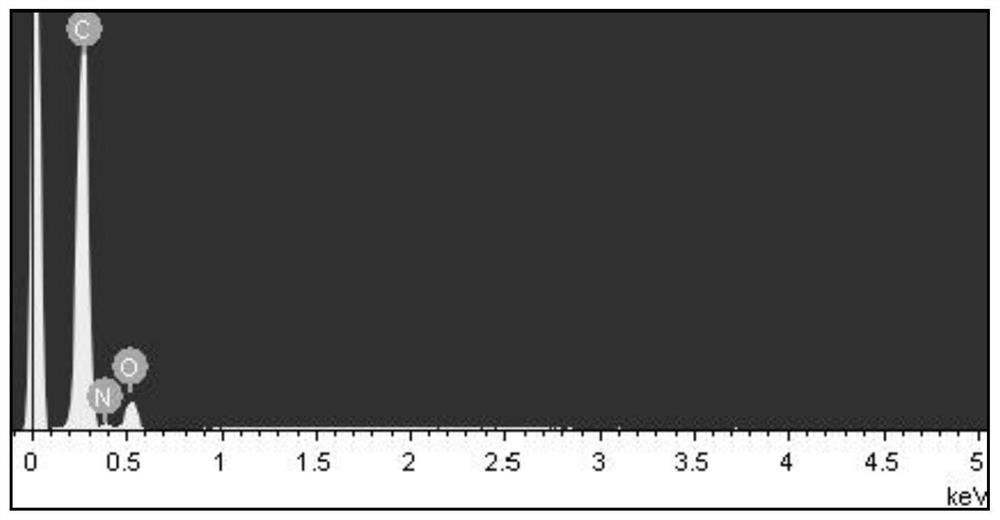

[0067] Place sample 2 on the electron microscope sample stage, wait for the electron microscope to be evacuated, apply a voltage of 20KV, and work at a distance of 10mm. Select a point with a flat surface and magnify it by 100 times for analysis. Record the elemental composition of the sample, the results are as figure 2 and as shown in Table 3, figure 2 Among them, the ordinate is the intensity of the peak, and the more the element content, the higher the peak. Table 3 shows the weight percentage and atomic percentage of C, N, and O elements quantitatively analyzed by the energy spectrometer. .

[0068] Table 3 Elemental composition of sample 2

[0069] element weight percentage atomic percent C 65.53 70.53 N 14.13 13.04 O 20.34 16.44 Total 100.00

[0070] The same method was used to analyze and repeat the test five times, and the specific elemental composition of the samples was averaged to calculate the average percentage of ...

Embodiment 3

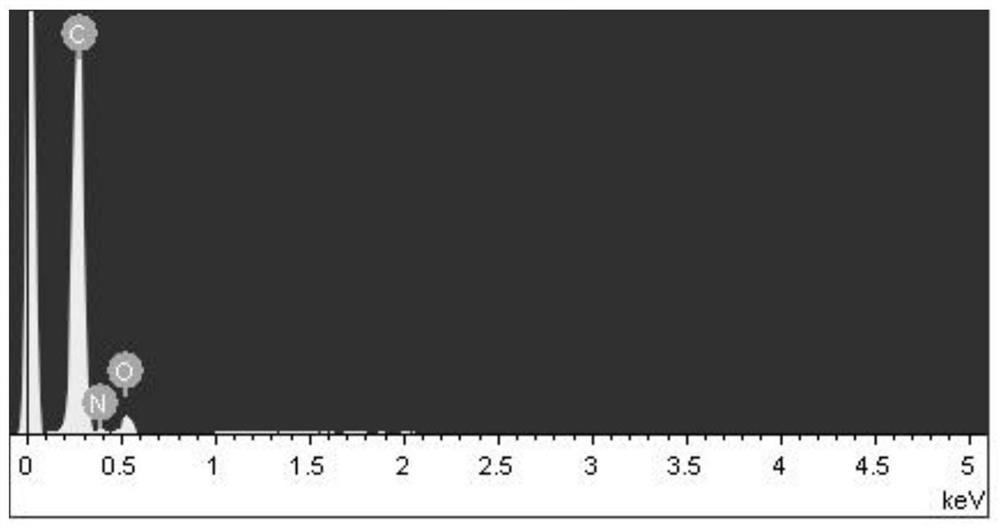

[0072] Place the sample 3 on the sample stage of the electron microscope, wait for the electron microscope to be evacuated, apply a voltage of 20KV, and have a working distance of 10mm. Select a point with a flat surface and magnify it by 100 times for analysis. Record the elemental composition of the sample, the results are as image 3 and as shown in Table 4, image 3 Among them, the ordinate is the intensity of the peak, and the more element content, the higher the peak. Table 4 shows the weight percentage and atomic percentage of C, N, and O elements quantitatively analyzed by energy spectrometer.

[0073] Table 4 Elemental composition of sample 3

[0074] element weight percentage atomic percent C 71.28 75.58 N 13.76 12.51 O 14.96 11.91 Total 100.00

[0075] The same method was used to analyze and repeat the test five times, and the specific elemental composition of the samples was averaged to calculate the average percentage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com