Method for preparing water-soluble cellulose from waste cotton

A technology of water-soluble cellulose and waste cotton, which is applied in the direction of cellulose pulp post-treatment, fiber raw material treatment, pulp property modification, etc., can solve the problem of low recycling rate of waste cotton, achieve less environmental pollution, and reduce raw material costs , high substitution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

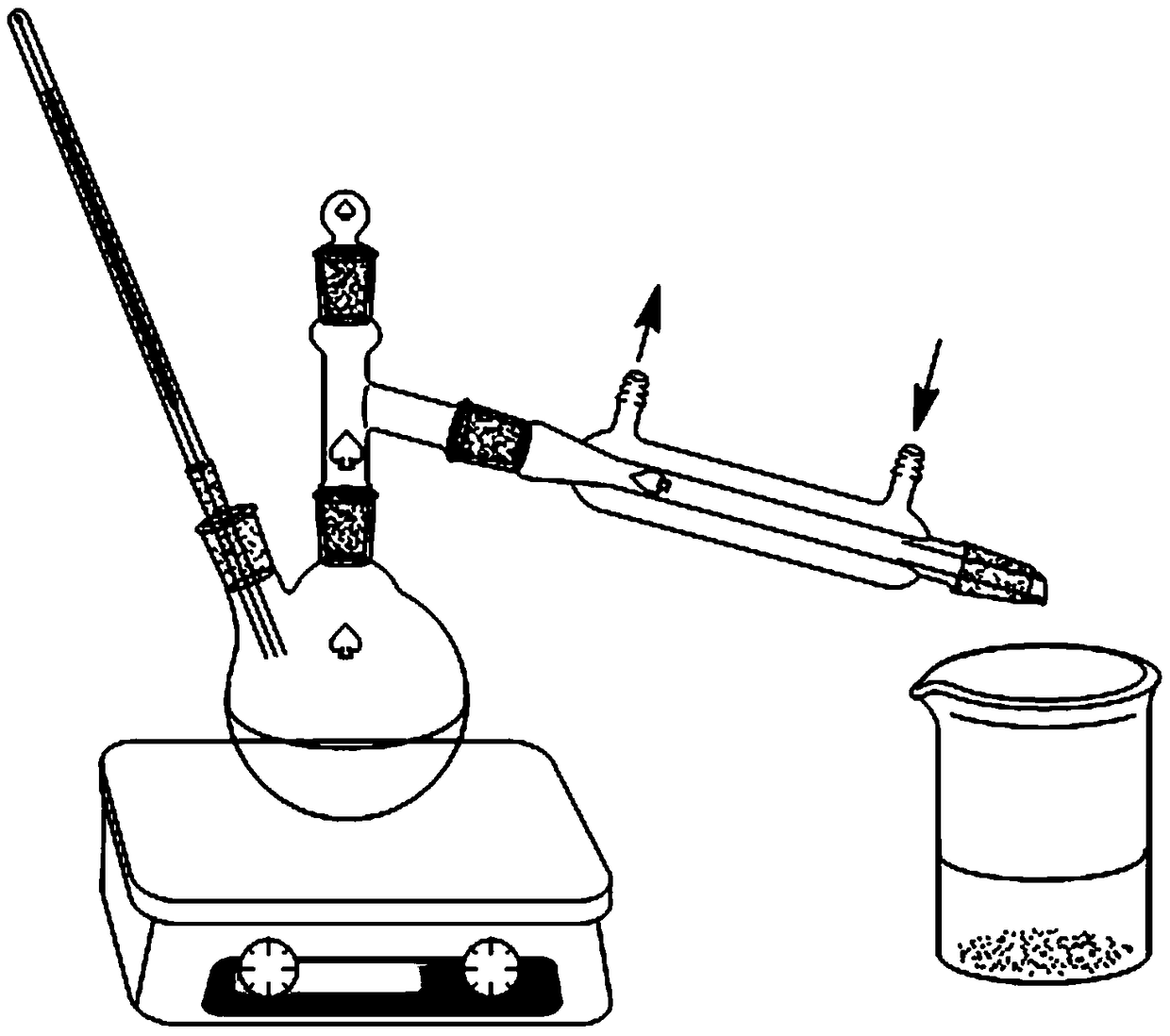

Method used

Image

Examples

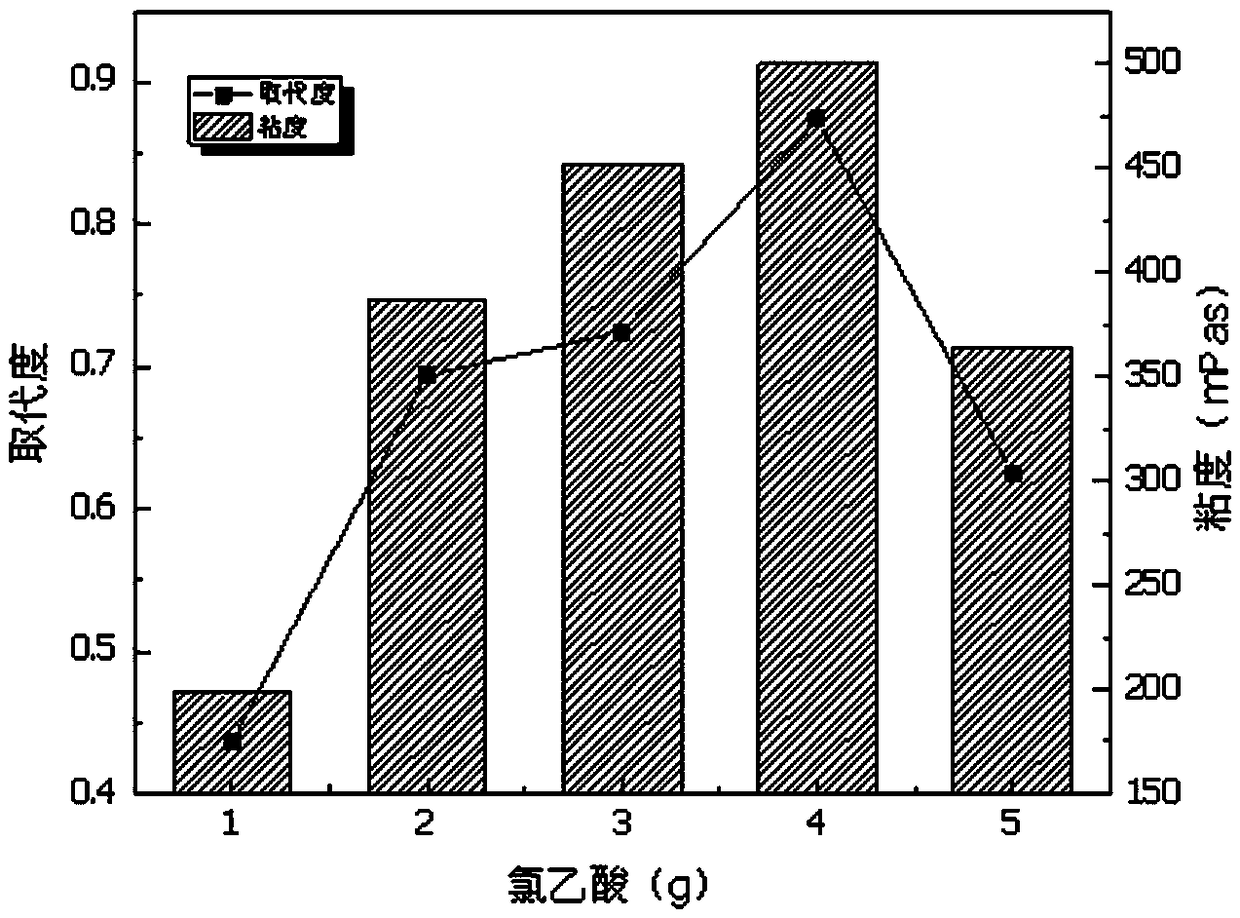

Embodiment 1

[0027] (1) Cut the waste cotton fabric into 5 mm pieces 2 square, wash and tumble dry. Weigh 10 g of sample, add it to a 600 mL beaker, add 1.5% hydrochloric acid solution, and stir at 400 r / min for 30 min at room temperature, so that the reactants are evenly dissolved or dispersed in water. Then, it was loaded into an autoclave and sealed, and the autoclave was filled to 60%. After being kept at the reaction temperature of 150°C for 3 h, the reaction product was naturally cooled to room temperature, and the reaction product was taken out and centrifuged. The separated solid cellulose powder was dried in a drying oven at 60 °C for 4 h, and dried for use.

[0028] (2) The cellulose isolated from waste cotton was converted into CMC in two steps: alkalization and etherification of cellulose. Weigh 5.0 g of cellulose powder, add it into a 500 mL Schott bottle, then add 30 mL of 40% sodium hydroxide solution, and stir at 50 °C for 20 min to obtain alkali cellulose. Weigh 1.5 g ...

Embodiment 2

[0030] (1) Cut the waste cotton fabric into 5 mm pieces 2 square, wash and tumble dry. Weigh 10 g sample, add it into a 600 mL beaker, add 1.5% hydrochloric acid solution, and stir at 400 r / min for 30 min at room temperature, so that the reactants are evenly dissolved or dispersed in water. Then, it was loaded into an autoclave and sealed, and the autoclave was filled to 60%. After being kept at the reaction temperature of 150°C for 3 h, the reaction product was naturally cooled to room temperature, and the reaction product was taken out and centrifuged. The separated solid cellulose powder was dried in a drying oven at 60 °C for 4 h, and dried for use.

[0031] (2) The cellulose isolated from waste cotton was converted into CMC in two steps: alkalization and etherification of cellulose. Weigh 5.0 g of cellulose powder, add it into a 500 mL Schott bottle, then add 30 mL of 40% sodium hydroxide solution, and stir at 50 °C for 20 min to obtain alkali cellulose. Weigh 1.5g of...

Embodiment 3

[0033] (1) Cut the waste cotton fabric into 5 mm pieces 2 square, wash and tumble dry. Weigh 10 g sample, add it into a 600 mL beaker, add 1.5% hydrochloric acid solution, and stir at 400 r / min for 30 min at room temperature, so that the reactants are evenly dissolved or dispersed in water. Then, it was loaded into an autoclave and sealed, and the autoclave was filled to 60%. After being kept at the reaction temperature of 150°C for 3 h, the reaction product was naturally cooled to room temperature, and the reaction product was taken out and centrifuged. The separated solid cellulose powder was dried in a drying oven at 60 °C for 4 h, and dried for use.

[0034] (2) The cellulose isolated from waste cotton was converted into CMC in two steps: alkalization and etherification of cellulose. Weigh 5.0 g of cellulose powder, add it into a 500 mL Schott bottle, then add 30 mL of 40% sodium hydroxide solution, and stir at 50 °C for 20 min to obtain alkali cellulose. Weigh 1.5g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com