In-situ doped nanometer molybdenum-based material as well as preparation method and application thereof

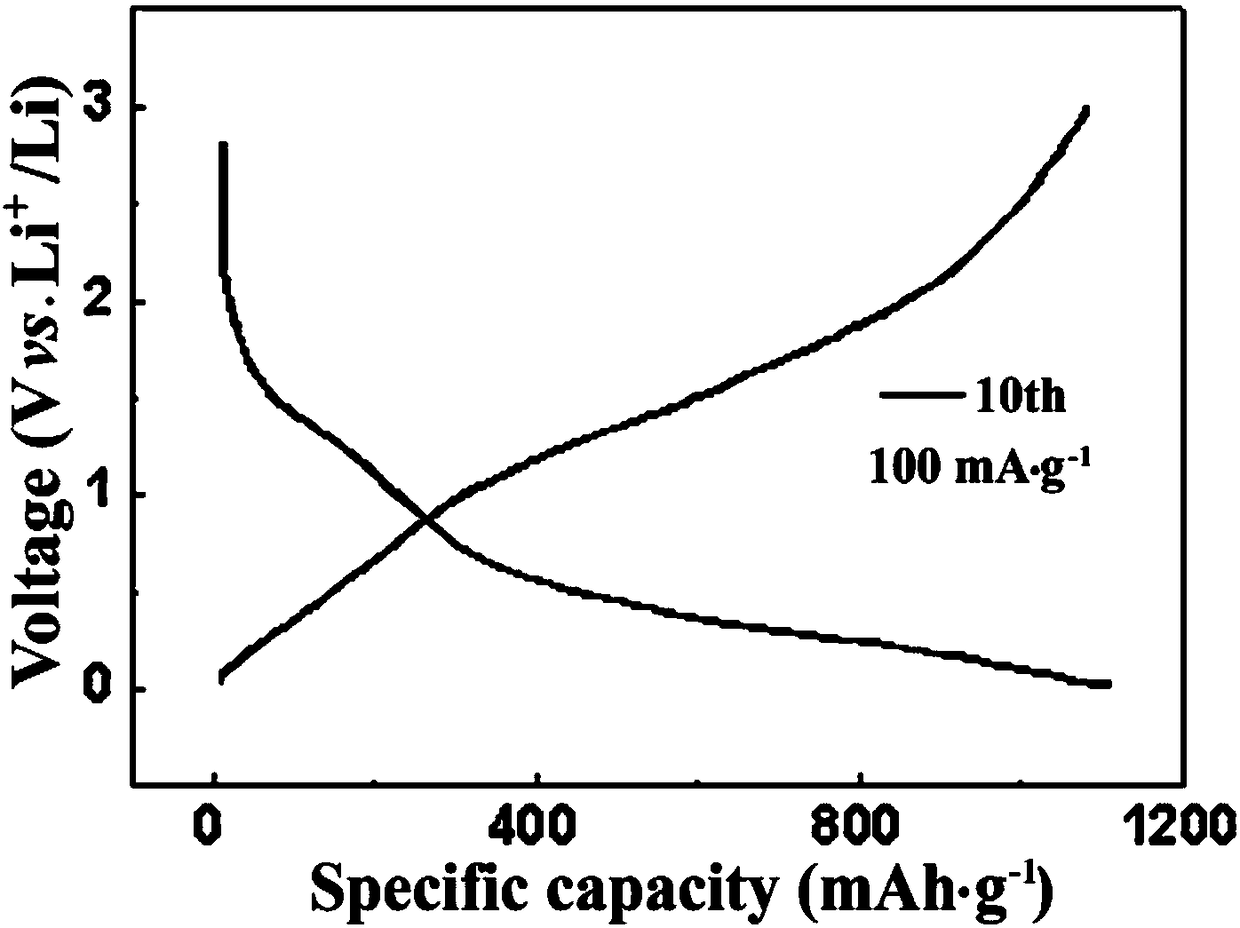

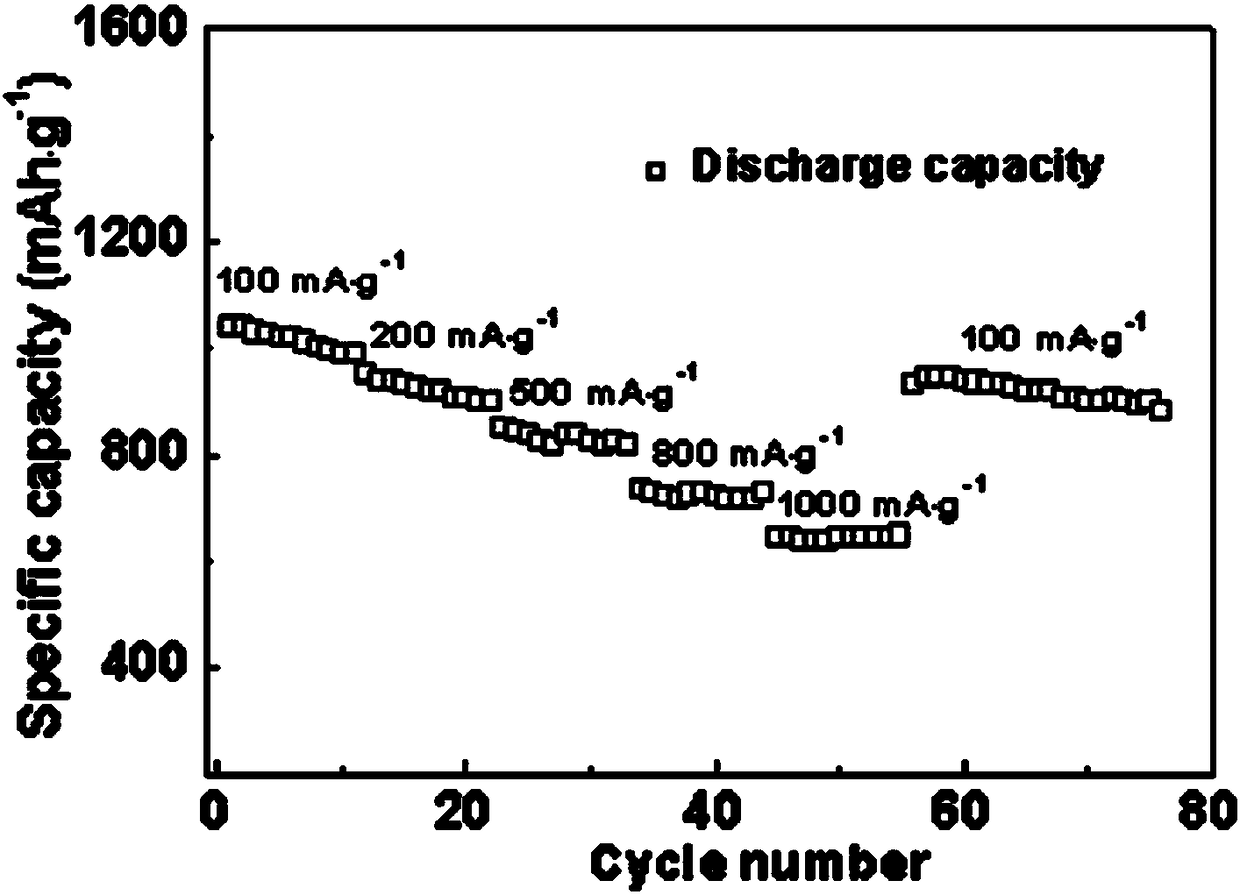

An in-situ doping and nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as difficult control of coating and doping, to improve electrochemical performance, Effect of high discharge specific capacity and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An in-situ doped nano-molybdenum-based material provided in an embodiment of the present invention, its preparation method specifically includes the following steps:

[0028] S1. Starting with 0.2200g of 1,6-bis(triazole)hexane, 2.4000g of ammonium heptamolybdate, 0.6475g of manganese chloride, 0.7999g of strontium chloride and 2.00mL of phosphoric acid, 36.00mL of water As a solvent, mix and stir for 60 minutes, adjust the pH value to 3 with sodium hydroxide to obtain a mixed solution;

[0029] S2. Transfer the mixed solution obtained in S1 to a reaction kettle, and react at 160° C. for 4 days. After the reaction, naturally cool to room temperature to obtain precursor reactant crystals;

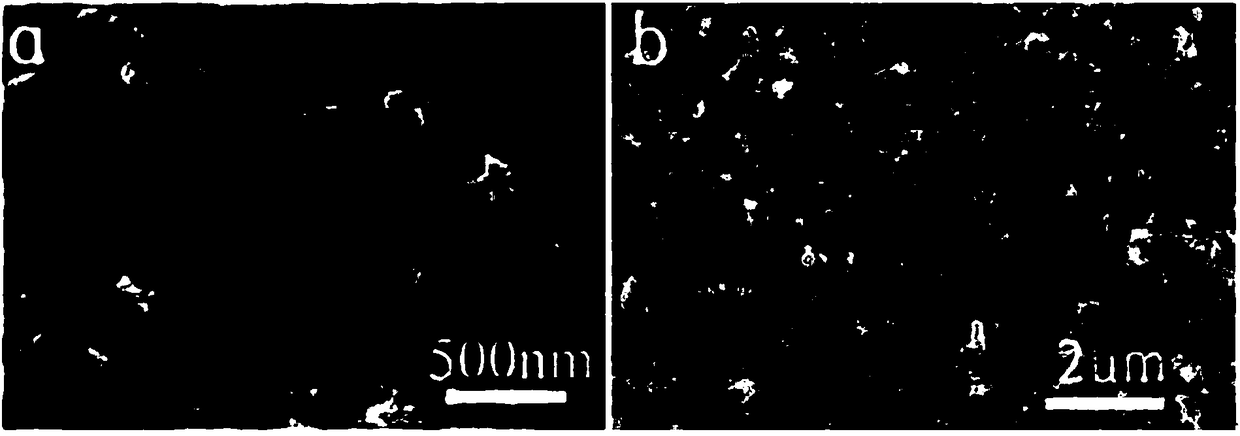

[0030] S3, the precursor reactant crystal obtained in S2 is washed, filtered, dried, and placed in a tube furnace under N 2 Under protection, it was calcined at 600°C for 8 hours. After the calcination, it was naturally cooled to room temperature to obtain a calcined product, and the...

Embodiment 2

[0033] An in-situ doped nano-molybdenum-based material provided in an embodiment of the present invention, its preparation method specifically includes the following steps:

[0034] S1. Starting with 0.2200g of 1,6-bis(triazole)hexane, 2.4000g of ammonium heptamolybdate, 0.6475g of manganese chloride, 0.7999g of strontium chloride and 2.00mL of phosphoric acid, 40.50mL of water As a solvent, mix and stir for 60 minutes, adjust the pH value to 3.5 with sodium hydroxide to obtain a mixed solution;

[0035] S2. Transfer the mixed solution obtained in S1 to a reaction kettle, and react at 160° C. for 5 days. After the reaction is completed, naturally cool to room temperature to obtain a reaction solution;

[0036] S3, the reaction solution obtained in S2 is washed, filtered, dried, and heated in a tube furnace under N 2 Under protection, it was calcined at 650°C for 7 hours. After the calcination, it was naturally cooled to room temperature to obtain a calcined product, and then ...

Embodiment 3

[0039] An in-situ doped nano-molybdenum-based material provided in an embodiment of the present invention, its preparation method specifically includes the following steps:

[0040]S1. Starting with 0.2200g of 1,6-bis(triazole)hexane, 2.4000g of ammonium heptamolybdate, 0.6475g of manganese chloride, 0.7999g of strontium chloride and 2.00mL of phosphoric acid, 45.00mL of water As a solvent, mix and stir for 60 minutes, adjust the pH value to 4 with sodium hydroxide to obtain a mixed solution;

[0041] S2. Transfer the mixed solution obtained in S1 to a reaction kettle, and react at 160° C. for 6 days. After the reaction is completed, naturally cool to room temperature to obtain a reaction solution;

[0042] S3, the reaction solution obtained in S2 is washed, filtered, dried, and heated in a tube furnace under N 2 Under protection, it was calcined at 700°C for 6 hours. After the calcination, it was naturally cooled to room temperature to obtain a calcined product, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com