Baked corn creep feed for suckling pigs and preparation method of baked corn creep feed

A technology for teaching trough feed and corn, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of not reaching the expected ripening degree, unstable corn ripening degree, etc., achieving stable gelatinization degree, improved amino acid, The effect of improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

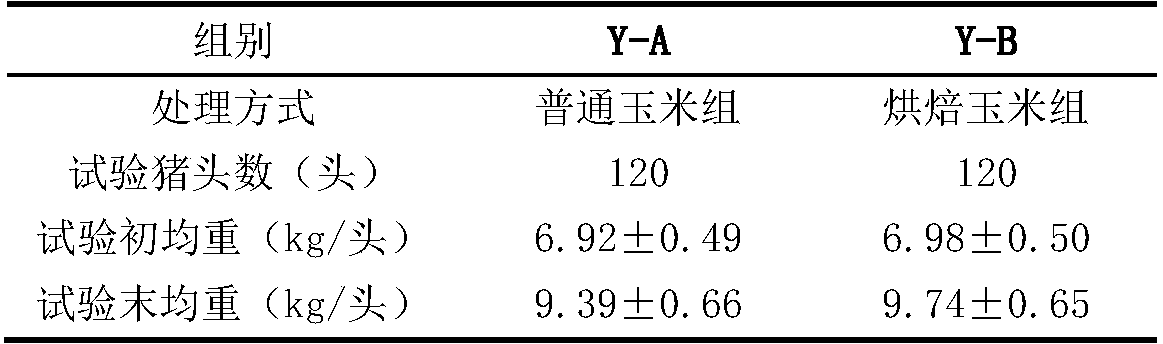

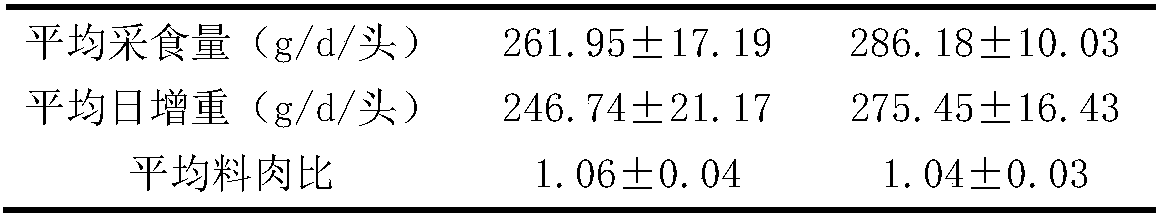

Examples

Embodiment 1

[0039]The roasted corn suckling pig creep feed includes the following components in parts by weight: 20-45 parts of corn, 5-20 parts of roasted corn, 5-15 parts of whey powder, 5-15 parts of soybean meal, 5-10 parts of expanded soybean, 1-10 parts of fermented soybean meal. 5. Skimmed milk powder 3-10, sucrose 1-5, plasma protein powder 0-5, organic compound acidifier 0.3-2, organic mineral premix 0.1-0.4, stone powder 0.1-0.8, calcium hydrogen phosphate 0.1-1.5, Amino acid 0.1-1.5, salt 0.1-0.4, choline chloride 0.05-0.3, vitamin premix 0.02-0.05, compound enzyme preparation 0.05-0.2, antifungal agent 0.05-0.5; wherein, the preparation method of the roasted corn includes Follow the steps below:

[0040] (1) Pass high-quality corn through double-layer vibrating screens, wind separators, stone removers, and permanent magnetic cylinders to obtain corn with complete grains and no impurities;

[0041] (2) Watering the high-quality corn after screening, soaking the corn for 4 hour...

Embodiment 2

[0060] The roasted corn suckling pig creep feed includes the following components in parts by weight: 20-45 parts of corn, 5-20 parts of roasted corn, 5-15 parts of whey powder, 5-15 parts of soybean meal, 5-10 parts of expanded soybean, 1-10 parts of fermented soybean meal. 5. Skimmed milk powder 3-10, sucrose 1-5, plasma protein powder 0-5, organic compound acidifier 0.3-2, organic mineral premix 0.1-0.4, stone powder 0.1-0.8, calcium hydrogen phosphate 0.1-1.5, Amino acid 0.1-1.5, salt 0.1-0.4, choline chloride 0.05-0.3, vitamin premix 0.02-0.05, compound enzyme preparation 0.05-0.2, antifungal agent 0.05-0.5; wherein, the preparation method of the roasted corn includes Follow the steps below:

[0061] (1) Pass high-quality corn through double-layer vibrating screens, wind separators, stone removers, and permanent magnetic cylinders to obtain corn with complete grains and no impurities;

[0062] (2) Watering the high-quality corn after screening, soaking the corn for 10 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com