Phosphorus-doped boron nitride acid-base catalyst and preparation method and application thereof

A boron nitride acid-base and phosphorus doping technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, cyanide reaction preparation, etc. Complicated process and other issues, to achieve the effect of excellent acid-base catalytic performance, cheap raw materials, stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

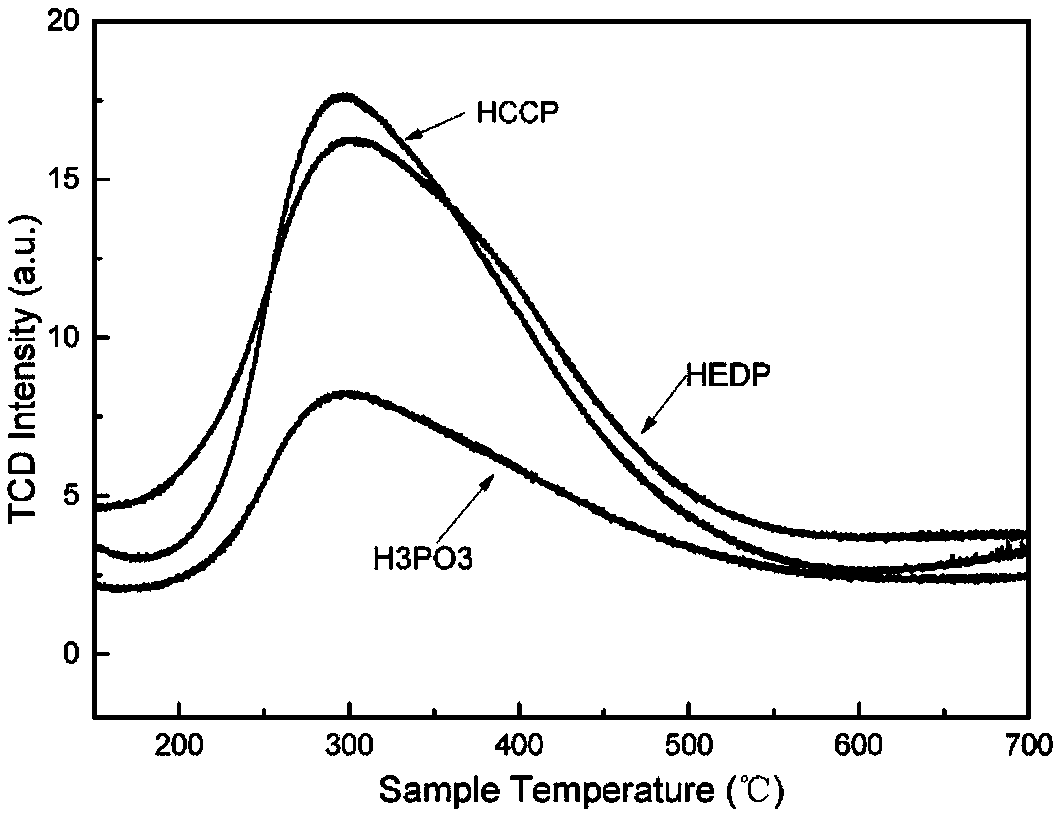

Embodiment 1

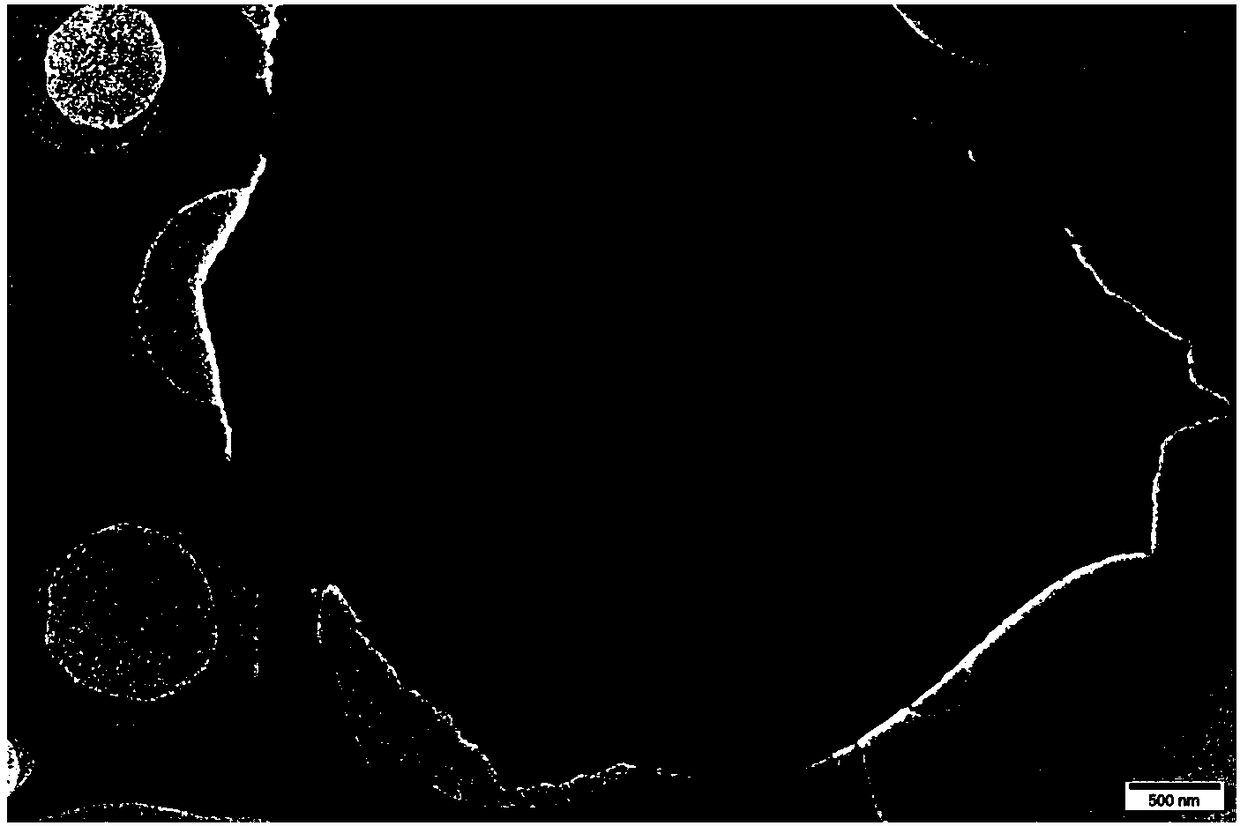

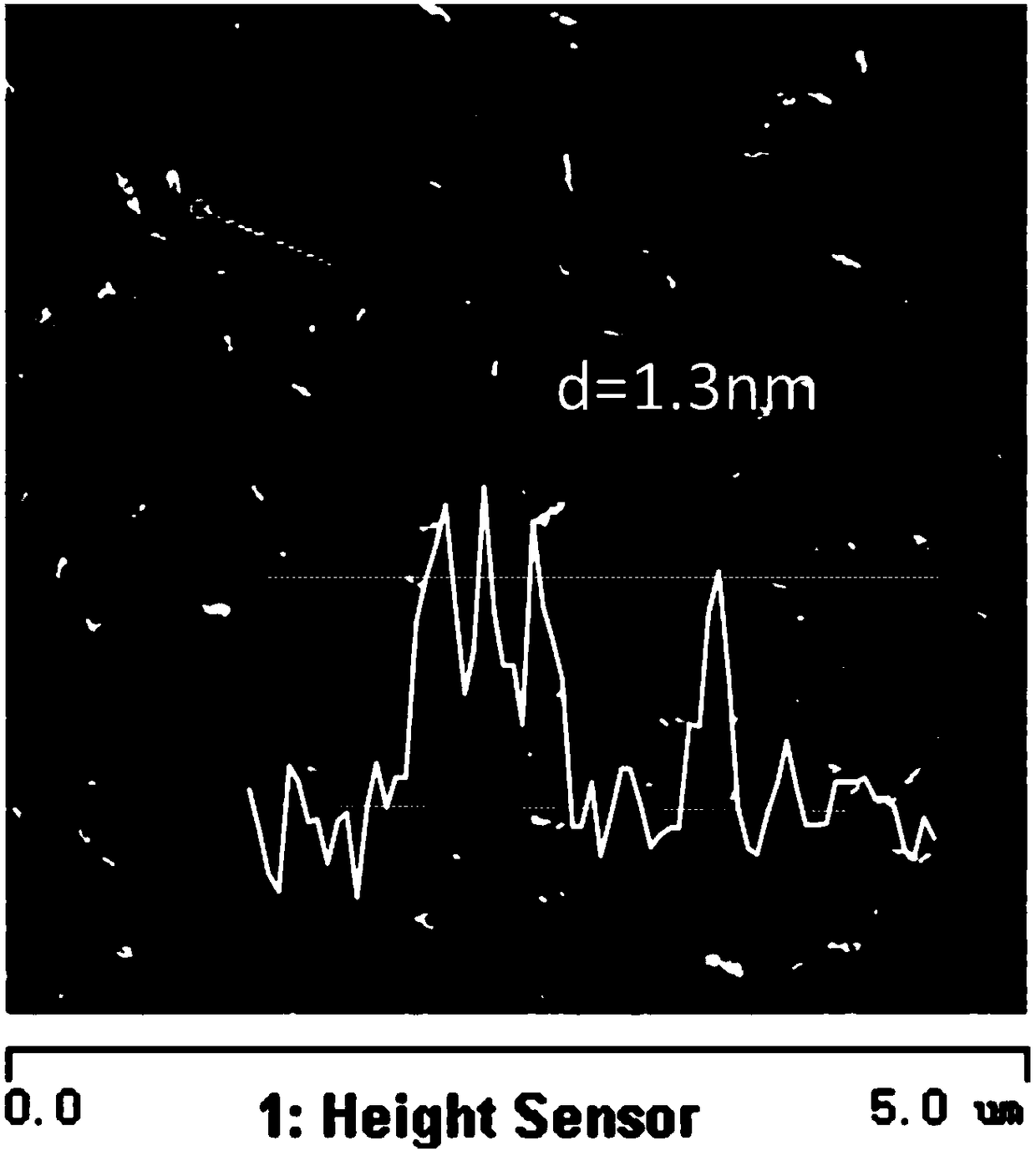

[0059] (a) Add 9.31g of urea, 0.4g of boric acid and 1.5g of phosphorous acid (the molar ratio of boron to phosphorus is 1:1.4) into 20ml of distilled water, stir until the materials are dissolved to obtain a solution, and then stir the solution at 65°C Recrystallize until there is no obvious moisture, and place the stirred recrystallized product in a vacuum drying oven at 50° C. for 8 hours.

[0060] (b) Place the dried recrystallized product in a corundum ark and then place it in a tube furnace, and feed N at a flow rate of 60ml / min 2 , heated up to 800°C at a rate of 5°C / min, kept roasting for 3h, and then in N 2 The BNP acid-base catalyst is obtained by lowering the temperature to room temperature.

Embodiment 2

[0062] (a) Add 9.31g of urea, 0.4g of boric acid and 2.21g of phosphorous acid (the molar ratio of boron to phosphorus is 1:2.1) into 20ml of distilled water, stir until the materials are dissolved to obtain a solution, and then stir the solution at 65°C Recrystallize until there is no obvious moisture, and place the stirred recrystallized product in a vacuum drying oven at 50° C. for 8 hours.

[0063] (b) Place the dried recrystallized product in a corundum ark and then place it in a tube furnace, and feed N at a flow rate of 60ml / min 2 , heated up to 800°C at a rate of 5°C / min, kept roasting for 3h, and then in N 2 The BNP acid-base catalyst is obtained by lowering the temperature to room temperature.

Embodiment 3

[0065] (a) Add 9.31g of urea, 0.4g of boric acid and 1.66g of hydroxyethylidene diphosphonic acid (the molar ratio of boron element to phosphorus element is 1:2.1), add 20ml of distilled water, stir until the material dissolves to obtain a solution, and then dissolve the solution Stir and recrystallize at 65°C until there is no obvious moisture, and place the stirred recrystallized product in a vacuum drying oven at 50°C for 8 hours.

[0066] (b) Place the dried recrystallized product in a corundum ark and then place it in a tube furnace, and feed N at a flow rate of 60ml / min 2 , heated up to 800°C at a rate of 5°C / min, kept roasting for 3h, and then in N 2 The BNP acid-base catalyst is obtained by lowering the temperature to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com