Method for solid-phase catalytic oxidation of polyaromatic hydrocarbon

A polycyclic aromatic hydrocarbon, catalytic oxidation technology, applied in the preparation of quinone oxide, organic chemistry and other directions, can solve the problems of full load, high energy consumption, easy carbonization and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

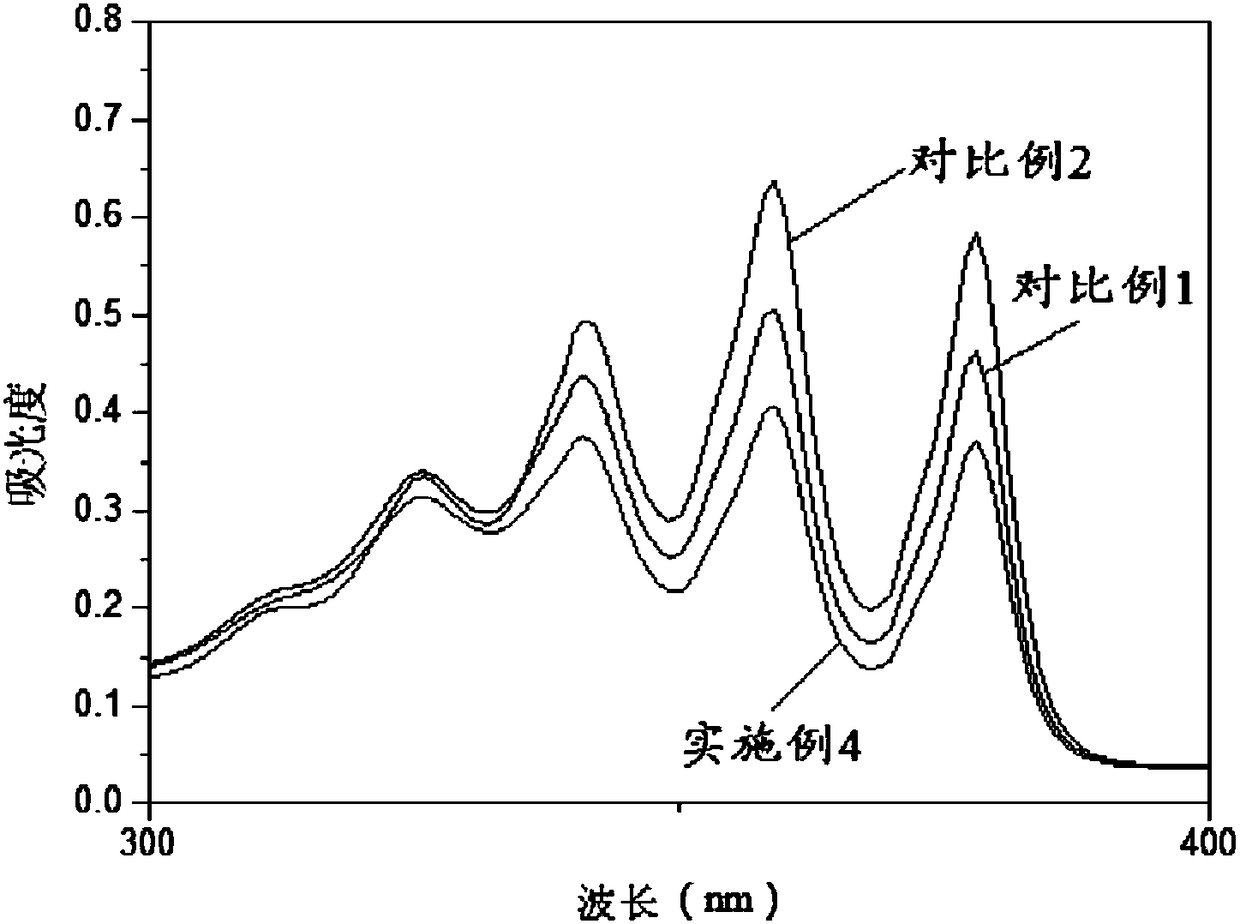

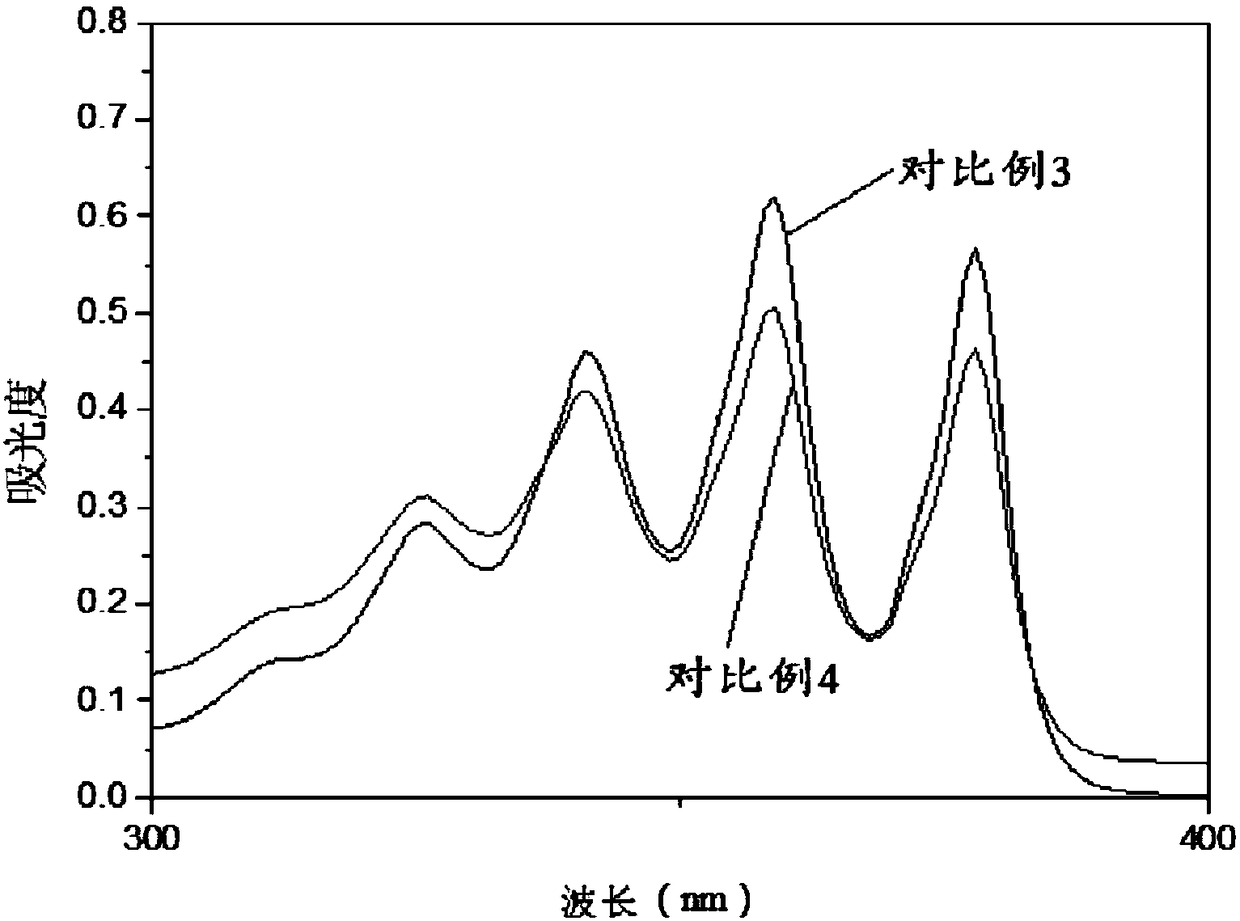

[0090] The catalytic oxidation of embodiment 1 phenanthrene

[0091] Weigh 0.02g phenanthrene and 0.6g sodium bismuthate, add to the petri dish, then add 14mL n-hexane to the petri dish, mix the three evenly, then let the methylene chloride volatilize naturally to obtain a solid phase mixture;

[0092] Put the solid-phase mixture into a microwave oven and react at 700W for 10min.

Embodiment 2

[0093] The catalytic oxidation of embodiment 2 pyrene

[0094] Weigh 0.02g of pyrene and 0.8g of sodium bismuthate, add them to the petri dish, then add 20mL of ethanol to the petri dish, mix the three evenly, then allow the ethanol to evaporate naturally to obtain a solid phase mixture;

[0095] Put the solid-phase mixture into a microwave oven and react at 700W for 10min.

Embodiment 3

[0096] The catalytic oxidation of embodiment 3 anthracene

[0097] Weigh 0.02g of anthracene and 1g of sodium bismuthate, add them to a petri dish, then add 20mL of dichloromethane to the petri dish, mix the three evenly, then allow the dichloromethane to volatilize naturally to obtain a solid phase mixture;

[0098] Put the solid-phase mixture into a microwave oven and react at 700W for 9min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com