Crosslinked PVD hard coating high-speed cutting tool and manufacturing method

A high-speed cutting, hard coating technology, applied in coating, metal material coating process, superimposed layer plating, etc., can solve the problems of reduced bending strength of tool materials, low bonding degree and high processing temperature, Reliable cross-linking, improved compounding ability, and improved flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

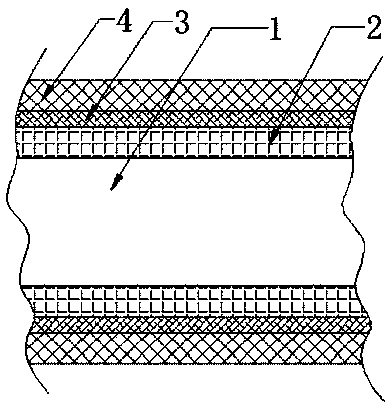

[0017] The cross-linked PVD hard-coated high-speed cutting tool of the present embodiment comprises a base material 1, a PVD coating 2 coated on the outside of the cemented carbide base material, said PVD coating 2 is a nano-coating, and the total thickness is 2-5 nanometers, the surface of PVD coating 2 is coated with diamond film 4, the outer surface of diamond film 4 has irregularly distributed dots through the impact of needles, and the periphery of diamond film 4 is coated with CVD coating 3, the said CVD The coating 3 is a metal nitride, and the PVD coating 2 and the CVD coating 3 are tightly and cross-linked into one body 4 through the diamond film 4 and the dots distributed on the diamond film.

[0018] A method for manufacturing a high-speed cutting tool with a cross-linked PVD hard coating as described above, comprising the following steps:

[0019] A. Deposit the PVD coating slurry on the substrate through a conventional process;

[0020] B. After the PVD coating i...

Embodiment 2

[0023] The cross-linked PVD hard-coated high-speed cutting tool of the present embodiment is characterized in that: it comprises a high-speed steel substrate 1, a PVD coating 2 coated outside the substrate, and said PVD coating 2 is a nano-coating, The total thickness is 2-5 nanometers, the surface of the PVD coating 2 is coated with a diamond film 4, and the outer surface of the diamond film 4 is impacted with irregularly distributed dots by a needle, and the periphery of the diamond film 4 is coated with a CVD coating 3, so The said CVD coating 3 is carbide or oxide, and the PVD coating 2 and CVD coating 3 are tightly and cross-linked together 4 through the diamond film 4 and the dots distributed on the diamond film.

[0024] A method for manufacturing a high-speed cutting tool with a cross-linked PVD hard coating as described above, characterized in that it includes the following steps:

[0025] A. Deposit the PVD coating slurry on the substrate through a conventional proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com