Non-toxic dual mode micropropulsion system and working method thereof

A micro-propulsion, dual-mode technology, which is applied to the propulsion system devices of space navigation vehicles, space navigation equipment, space navigation vehicles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

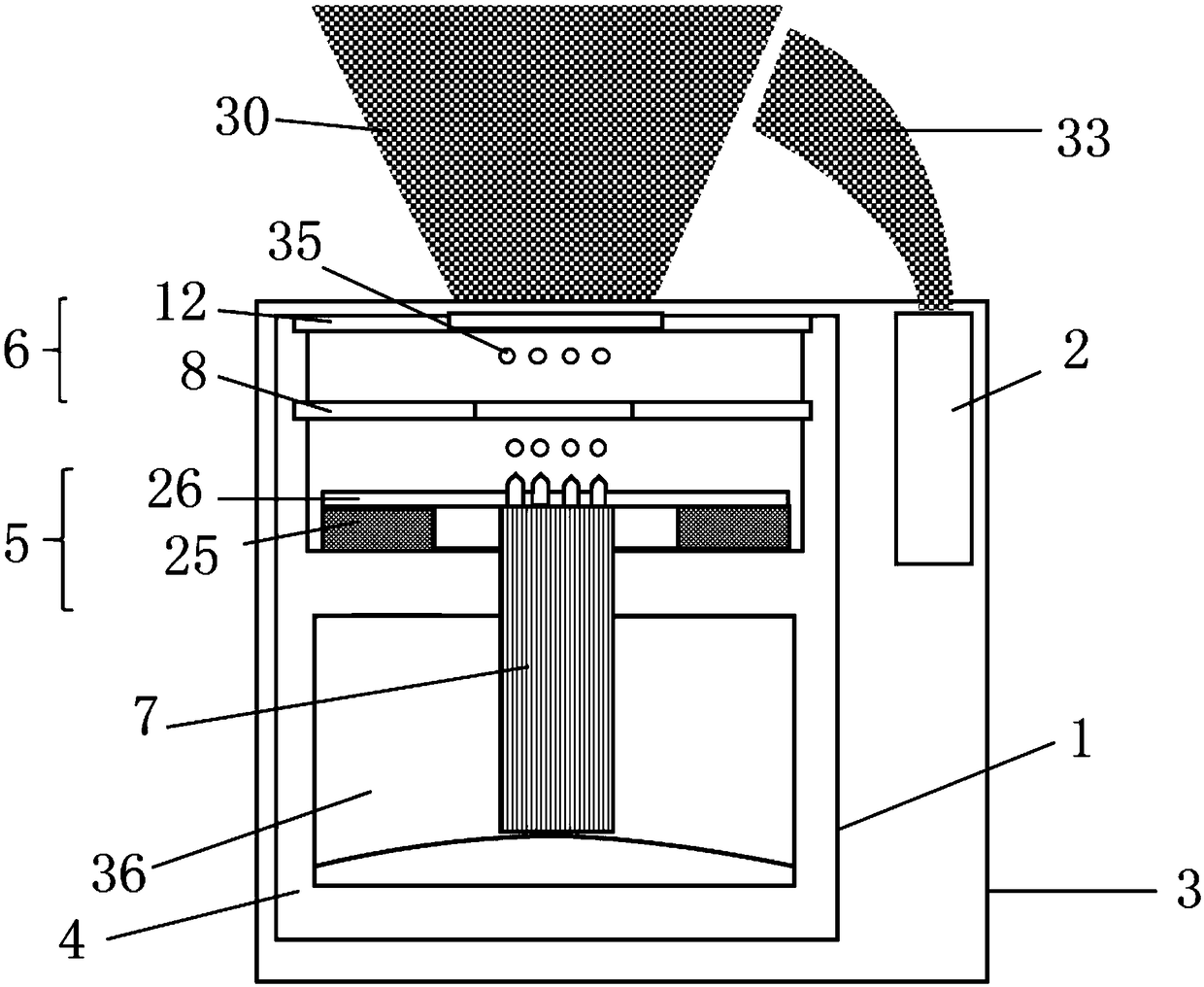

Embodiment 1

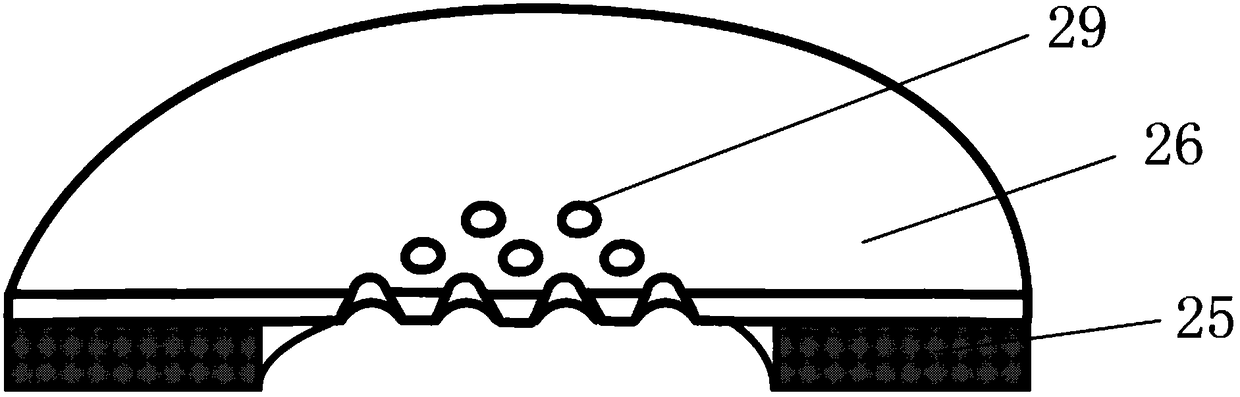

[0090] The non-toxic dual-mode micro-propulsion system of the present invention has a thruster body 1 with a diameter of 20mm, a spray ultrasonic vibration unit 5 with a frequency of 180kHz, a diameter of 15mm, a spray grid 26 with a diameter of 15mm, and 320 pieces with a top diameter of 2μm and a bottom diameter of 30μm distributed in the center Tapered grid holes 29, the distance between the grid holes 29 is 0.13mm. The propellant 36 adopts EMI-Im (1-ethyl-3-methylimidazoline bis(trifluoromethylsulfonyl)imide) ionic liquid, the storage capacity is 30ml, and the injection shell 4 is made of polyether ether ketone. The jet transport element 7 is made of fibers. The neutralizer 2 adopts a carbon nanotube field emission neutralizer that does not require propellants, and has a diameter of 15 mm. The carbon nanotube emitter 15 is used to emit electrons, and the electrons can be extracted by applying a certain voltage to the neutralizer grid 14 . The power processing unit 3 is co...

Embodiment 2

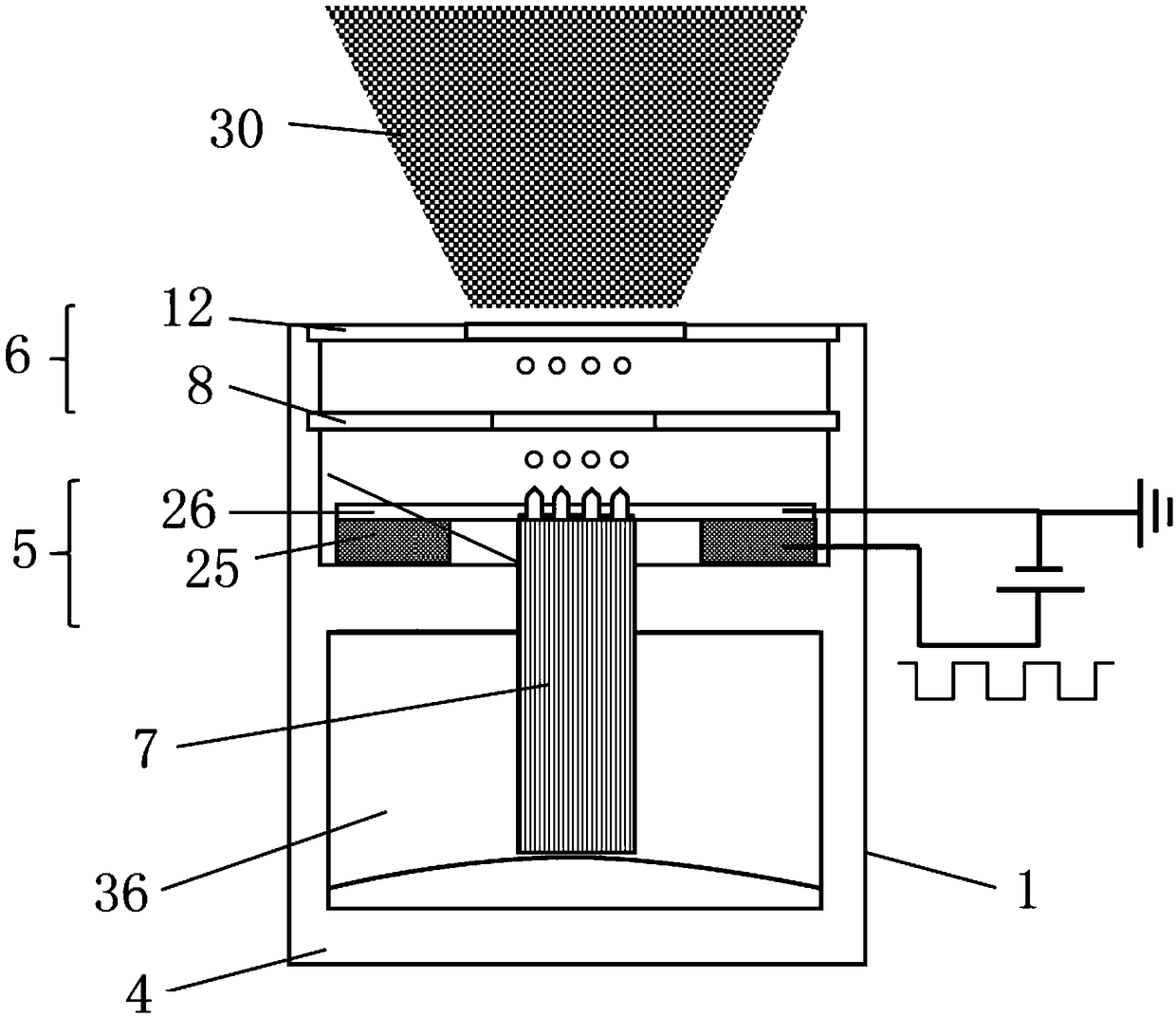

[0095] In the non-toxic dual-mode micro propulsion system of the present invention, the thruster body 1 and the neutralizer 2 adopt modules with the same structure. The neutralization shell 16 of the neutralizer 2 has a diameter of 20mm, and adopts a 180kHz frequency neutralization ultrasonic vibration unit 17 with a diameter of 15mm, a neutralization grid 28 with a diameter of 15mm, and 320 cones with a top diameter of 2μm and a bottom diameter of 30μm distributed in the center Grid hole 29, the distance between grid hole 29 is 0.13mm. The propellant 36 adopts EMI-Im (1-ethyl-3-methylimidazoline bis(trifluoromethylsulfonyl)imide) ionic liquid, the storage capacity is 30ml, and passes through. Neutralizing housing 16 is made of polyether ether ketone. The neutralization transport element 19 is made of fibers. The neutralization electrostatic acceleration unit 18 is composed of a neutralization extraction pole 20 and a neutralization acceleration pole 21 .

[0096] Thruster ...

Embodiment 3

[0100] In the non-toxic dual-mode micro-propulsion system of the present invention, the electrostatic acceleration grid of the thruster body 1 only adopts a jetting extraction pole 8, and the jetting extraction pole 8 also takes into account the charged particle acceleration function, and the corresponding power processing unit 3 is composed of jetting ultrasonic drive power supply 10, jet Draw out power supply 9 and neutralizer power supply 11 lamp modules to form. When the thruster body 1 works in the electrostatic spraying mode, the ejection pole 8 is negatively charged, and the sprayed particles are positively charged droplets, and the droplets are ejected by the electrostatic field formed by the ejection pole 8 and the spray grid 26 to generate thrust . Neutralizer 2 ejects neutralization stream 33 for neutralization. According to the difference in the voltage of the ejection electrode 8, the ejection speed of the body beam is different. The higher the voltage, the faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com