Water-soluble photosensitive resin composition, cover film and circuit board

A photosensitive resin, water-soluble technology, applied in the direction of circuit substrate materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as easy pollution of the environment, hidden safety hazards, environmental pollution, etc., achieve strong adhesion, save resources, and reduce storage costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

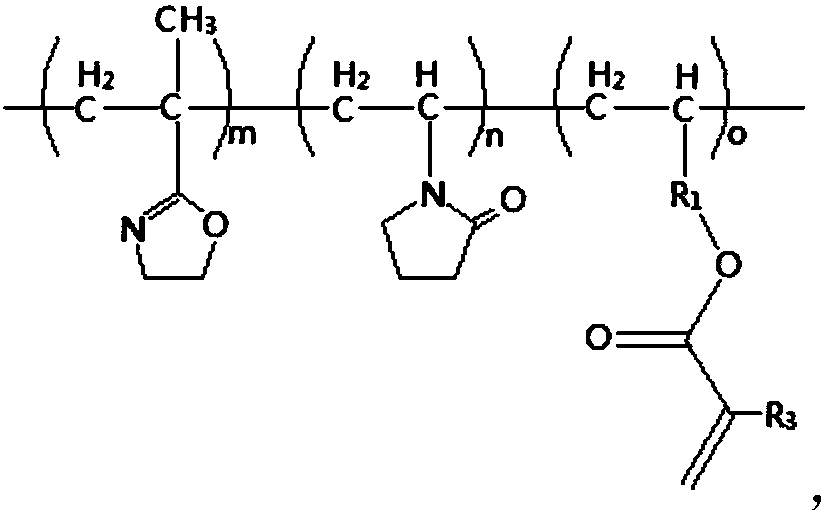

[0052] The preparation method of the water-soluble photosensitive resin composition can be as follows: adding polymers containing oxazoline groups, photosensitive monomers, photoinitiators, colorants and pure water into the reaction bottle according to a predetermined ratio, mixing and stirring, The polymer containing the oxazoline group, the photosensitive monomer, the photoinitiator and the colorant are mixed evenly to obtain the water-soluble photosensitive resin composition. The amount of pure water added can be changed as required, as long as the polymer containing oxazoline group, photosensitive monomer, photoinitiator, and colorant can be completely dissolved or dispersed.

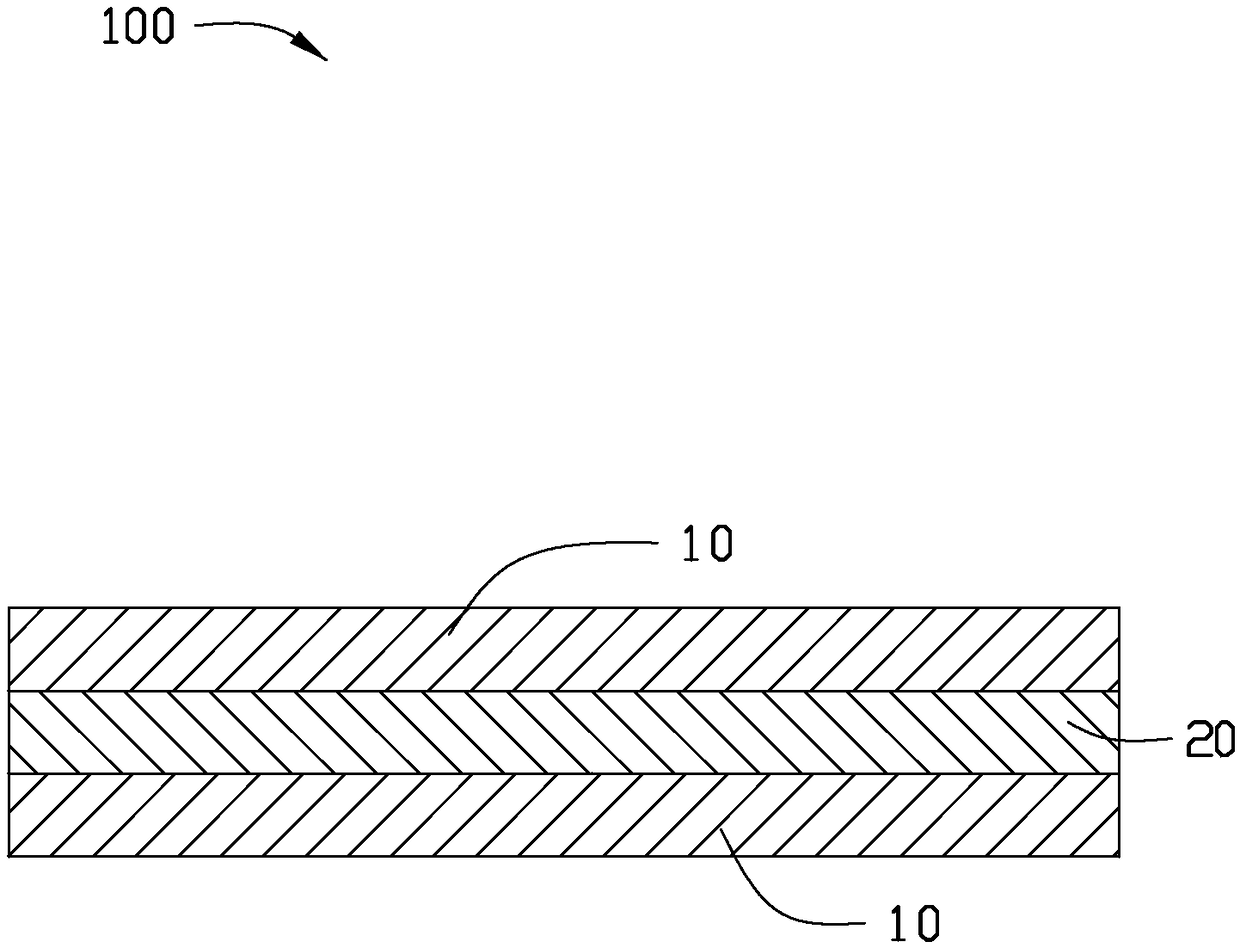

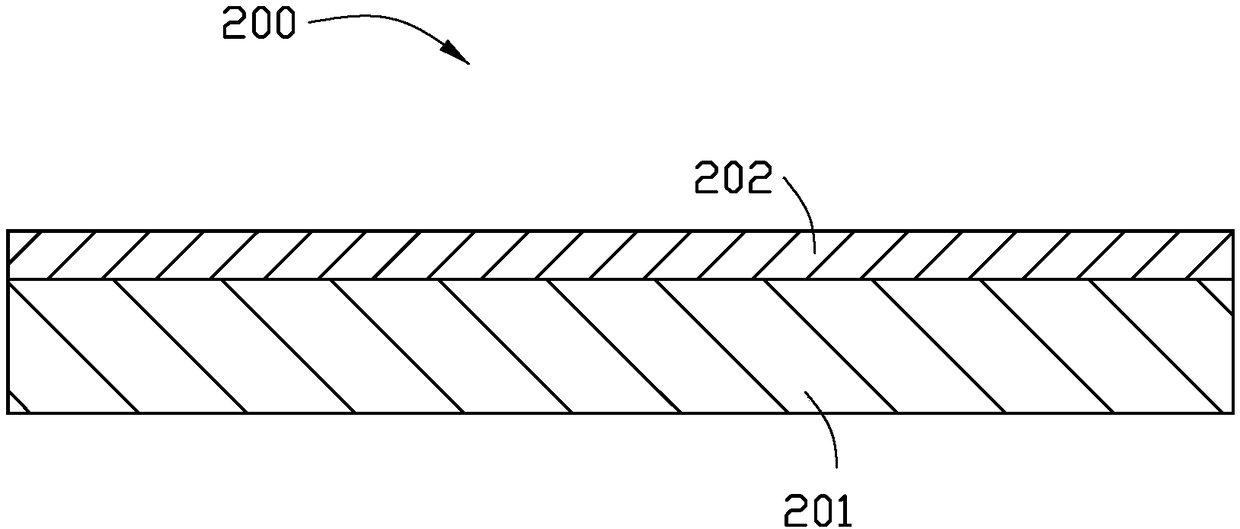

[0053] see figure 1 , a cover film 100 comprising a photosensitive resin layer 20 and a release film 10 bonded to at least one surface of the photosensitive resin layer 20 . The photosensitive resin layer 20 is formed by coating the above water-soluble photosensitive resin composition on the surfac...

Embodiment 1

[0058] Add 100 g of oxazoline-based polymer, 40 g of ethoxylated trimethylolpropane tri(meth)acrylate, 8 g of phenyl bis(2,4,6-tri Toluyl)phosphine oxide, 2g of colorant, 100g of pure water, and 30g of barium sulfate were stirred and dissolved to obtain a water-soluble photosensitive resin composition.

[0059] Wherein, the molecular weight of the polymer containing oxazoline groups is 20000 g / mol.

Embodiment 2

[0061] To a reaction flask with a volume of 500ml, 100g of polymer containing oxazoline group, 20g of ethoxylated trimethylolpropane tri(meth)acrylate, 8g of phenylbis(2,4,6-tri Toluyl)phosphine oxide, 2g of colorant, 100g of pure water, and 15g of barium sulfate were stirred and dissolved to obtain a water-soluble photosensitive resin composition.

[0062] Wherein, the molecular weight of the polymer containing oxazoline groups is 20000 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com