Ageing process for improving strength non-uniformity of quenched large-size 7-series aluminum alloy

An aluminum alloy, large-scale technology, applied in the field of aging heat treatment process, can solve the problems of not being suitable for industrial production, reducing quenching sensitivity, etc., and achieve the effects of low cost, reduced strength non-uniformity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that the embodiments are only used to illustrate the present invention, but not to limit the protection scope of the present invention. Improvements and adjustments made by skilled personnel according to the present invention in practical applications still belong to the protection scope of the present invention.

[0027] The aluminum alloy selected in the example is a common commercial 7A09 aluminum alloy, and its quenching sensitivity is very high. The specific content of each alloy element is: Zn: 5.7; Mg: 2.5; Cu: 1.6; Mn: 0.15; Fe: 0.5; Cr: 0.26; Si: 0.50; Ti: 0.1; Al: balance (wt.%). The alloy is a fully homogenized hot-rolled plate with a thickness of 35 mm.

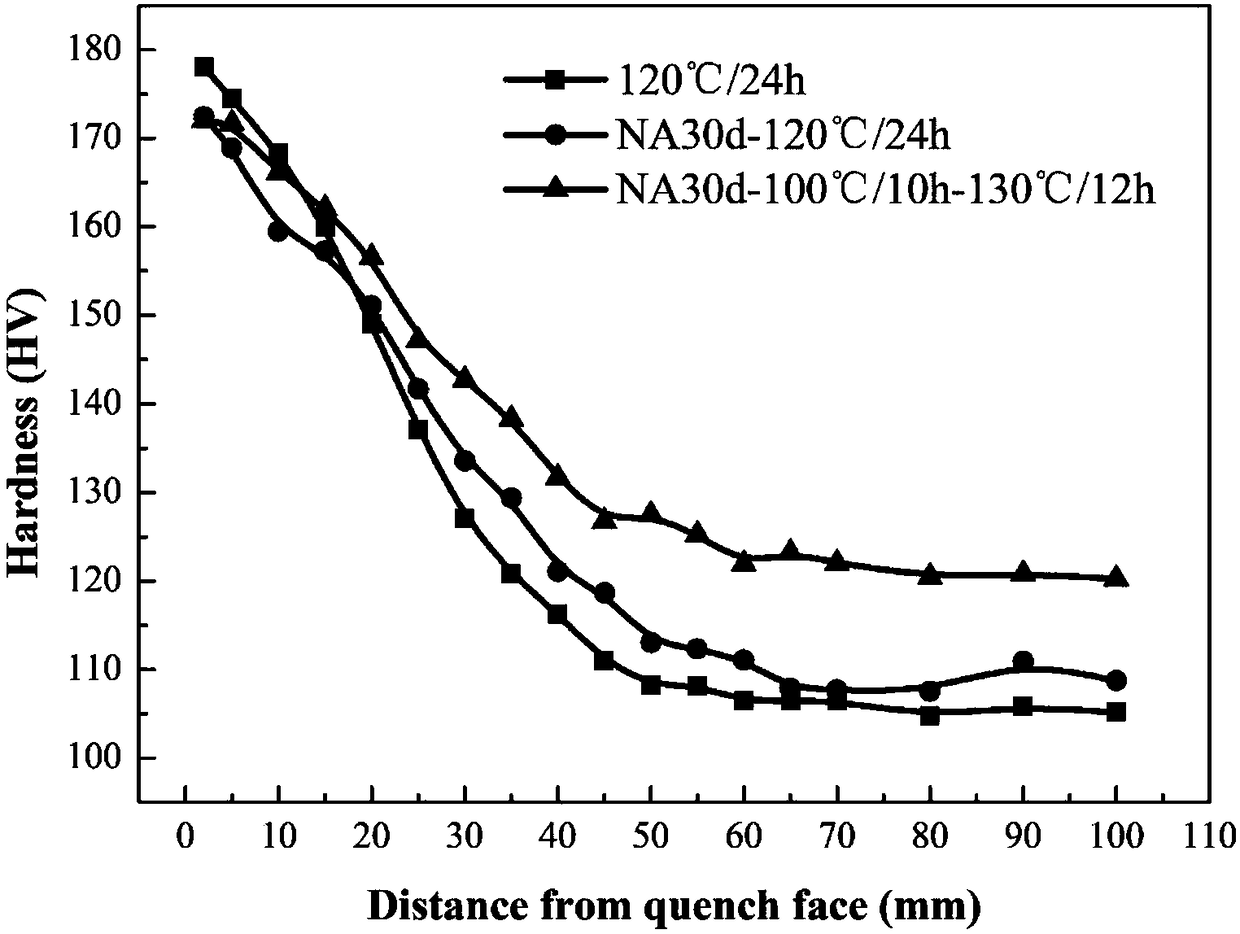

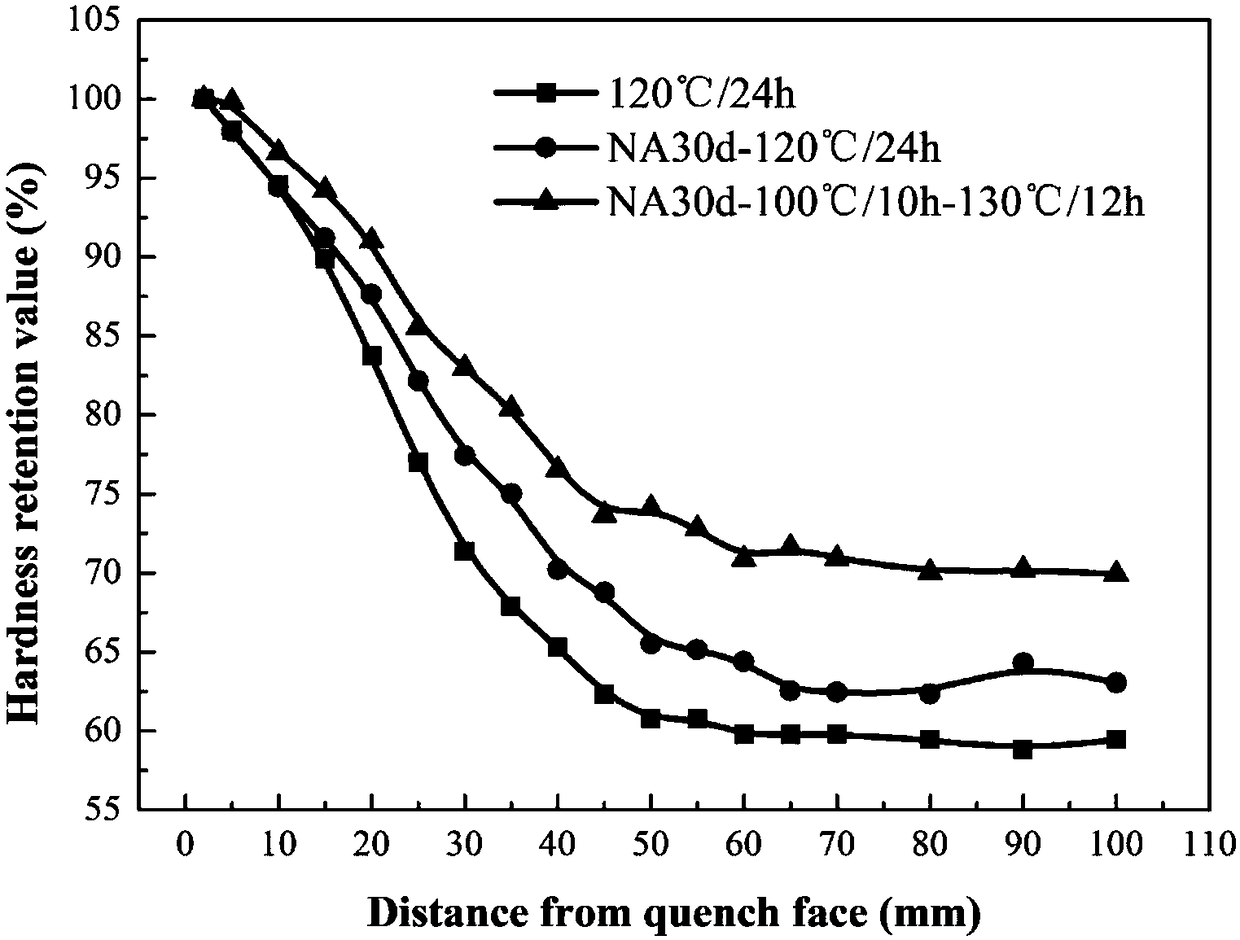

[0028] In this example, the end quenching experiment is used to reflect the advantages of natural aging combined with double-stage artificial aging. The example selects three groups of aged sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com