A kind of copolymerized polymer chelating flocculant and preparation method thereof

A polymer and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the problems of slow sedimentation, weak chelation ability, small flocs, etc., and achieve less pollution , Enhanced chelating ability, thicker flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

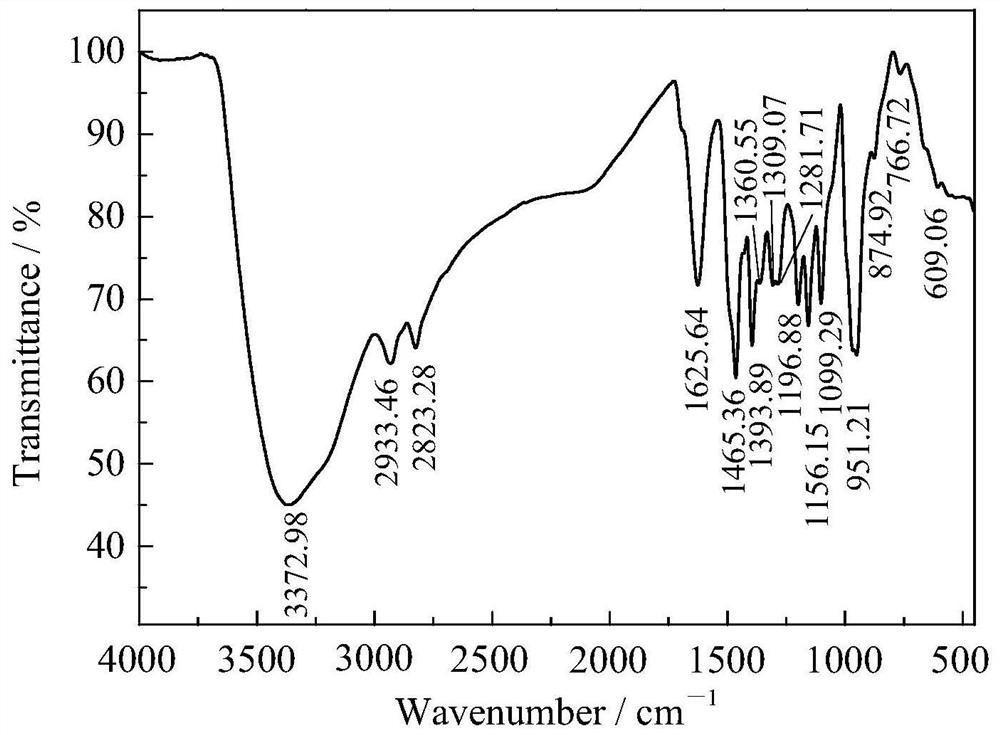

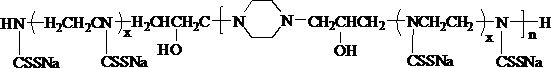

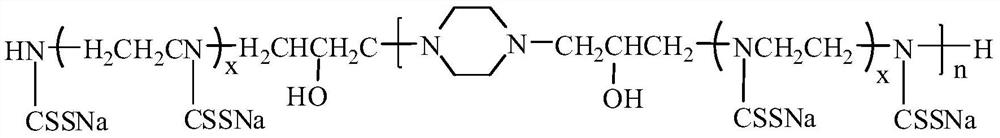

Image

Examples

Embodiment 1

[0027] (1) Get the piperazine 2.16g that mass fraction is 99.5% and join in the three-necked bottle of 250mL band mechanical stirring, reflux condenser and dropping funnel, then add 108.0g dehydrated alcohol, after fully dissolving, add mass fraction is 5.9 mL of 95.0% triethylenetetramine, then heated up to 60°C, slowly added 2.97 mL of epichlorohydrin with a mass fraction of 99.0% dropwise within 30 minutes, and continued the reaction for 3 hours after the addition;

[0028] (2) The reaction mixture obtained in step (1) was rotary-evaporated at 60°C and -0.095MPa until no more solvent dripped out to obtain 10.37g of light yellow sticky substance; collected 96.3g of ethanol;

[0029] (3) Transfer the viscous matter obtained in step (2) into a 500mL three-necked bottle with mechanical stirring, reflux condenser and dropping funnel, add 207.4g of distilled water, stir to dissolve, and then add 6.875g with a mass fraction of 96.0% After dissolving, slowly add 9.18 mL of carbon d...

Embodiment 2

[0033](1) Take 2.16g of piperazine with a mass fraction of 99.5% and add it to a 250mL three-necked bottle with mechanical stirring, reflux condenser and dropping funnel, then add the 96.3g ethanol collected in Example 1, after fully dissolving, add 7.1mL of triethylenetetramine with a mass fraction of 95.0%, then raised the temperature to 65°C, slowly added 3.56mL of epichlorohydrin with a mass fraction of 99.0% dropwise within 35min, and continued the reaction for 2.5h after the addition;

[0034] (2) The reaction mixture obtained in step (1) was rotary-evaporated at 60°C and -0.095MPa until no more solvent dripped out to obtain 10.49g of light yellow viscous substance; 86.9g of ethanol was collected;

[0035] (3) Transfer the viscous matter obtained in step (2) into a 500mL three-necked bottle with mechanical stirring, reflux condenser and dropping funnel, add 262.3g of distilled water, stir to dissolve, and then add 8.625g of 96.0% mass fraction After dissolving, slowly ad...

Embodiment 3

[0037] (1) Take 2.16g of piperazine with a mass fraction of 99.5% and add it to a 250mL three-necked bottle with mechanical stirring, reflux condenser and dropping funnel, then add the 86.4g ethanol collected in Example 2, after fully dissolving, add 7.87mL of triethylenetetramine with a mass fraction of 95.0% was then heated up to 60°C, and 3.96mL of epichlorohydrin with a mass fraction of 99.0% was slowly added dropwise within 35min, and the reaction was continued for 2h after the addition;

[0038] (2) The reaction mixture obtained in step (1) was rotary-evaporated at 60°C and -0.095MPa until no more solvent dripped out to obtain 10.84g of light yellow sticky substance; collected 75.9g of ethanol;

[0039] (3) Transfer the viscous matter obtained in step (2) into a 500mL three-necked bottle with mechanical stirring, reflux condenser and dropping funnel, add 325.2g of distilled water, stir and dissolve, then add 10.83g of 96.0% mass fraction After dissolving sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com