Chromium-free anti-oxidation solution and anti-oxidation process for electrolytic copper foil for lithium ion batteries

A technology of lithium ion battery and anti-oxidation solution, which is applied in the field of surface treatment of electrolytic copper foil, can solve the problems of lower battery capacity and charge and discharge performance, high temperature of winding house, explosion, etc., and achieve high wettability and conductivity, The effect of uniform passivation film and simple process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

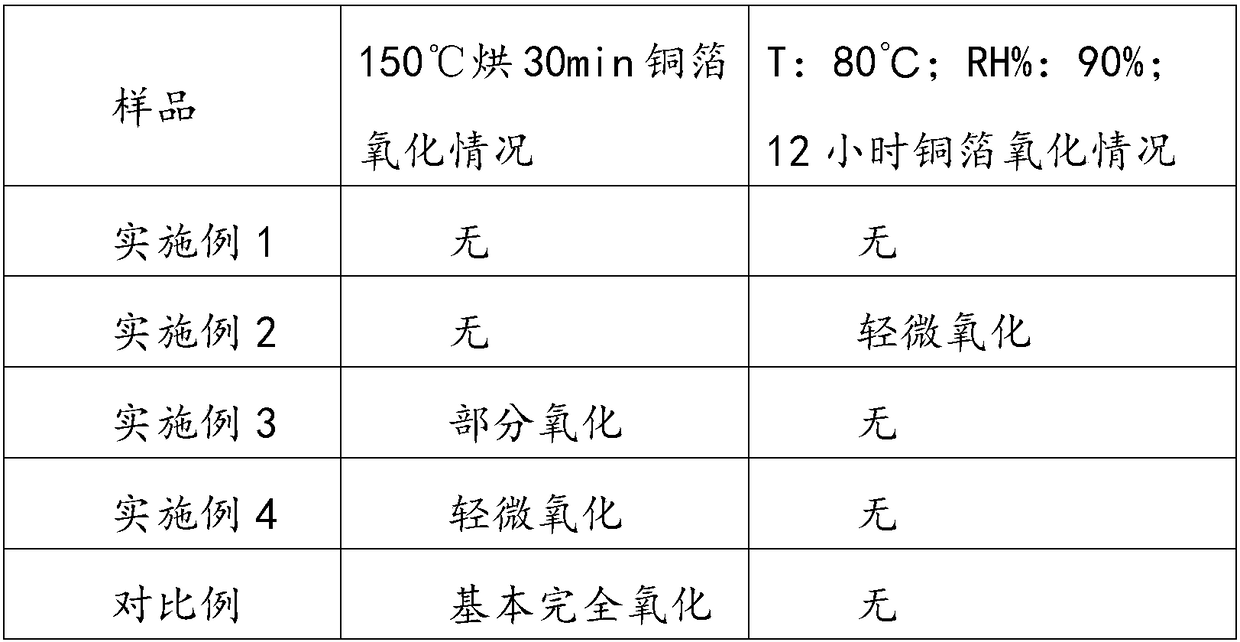

Examples

Embodiment 1

[0025] A chromium-free anti-oxidation solution for electrolytic copper foil for lithium ion batteries, comprising the following components: benzotriazole 0.8 g / L; benzoic acid 0.5 g / L; propyl acetate 0.3 g / L, and the solvent is water.

[0026] The process of using the above-mentioned chromium-free anti-oxidation solution to carry out surface anti-oxidation treatment of electrolytic copper foil includes the following steps: After the original foil is stripped by the cathode roller, it is soaked in the chromium-free anti-oxidation solution through the guide roller, and the chromium-free anti-oxidation solution is controlled during the soaking process. The temperature of the oxidizing solution is 24°C, the soaking time is 5s, and then it is squeezed dry by a squeeze roller, blown dry with a high-pressure air knife at room temperature, and then directly wound up, which is a semi-finished product.

Embodiment 2

[0028] A chrome-free anti-oxidation solution for electrolytic copper foil for lithium ion batteries, comprising the following components: benzotriazole 0.2 g / L; benzoic acid 1.2 g / L; propyl acetate 1.0 g / L, and the solvent is water.

[0029] The process of using the above-mentioned chromium-free anti-oxidation solution to carry out surface anti-oxidation treatment of electrolytic copper foil includes the following steps: After the original foil is stripped by the cathode roller, it is soaked in the chromium-free anti-oxidation solution through the guide roller, and the chromium-free anti-oxidation solution is controlled during the soaking process. The temperature of the oxidizing solution is 35°C, and the soaking time is 6s. After that, it is squeezed dry by a squeeze roller, blown dry with a high-pressure air knife at room temperature, and then rolled directly, which is a semi-finished product.

Embodiment 3

[0031] A chrome-free anti-oxidation solution for electrolytic copper foil for lithium ion batteries, comprising the following components: benzotriazole 2.0 g / L; benzoic acid 0.1 g / L; propyl acetate 0.5 g / L, and the solvent is water.

[0032] The process of using the above-mentioned chromium-free anti-oxidation solution to treat the surface of electrolytic copper foil for anti-oxidation includes the following steps: After the original foil is stripped by the cathode roller, it is soaked in the chromium-free anti-oxidation solution through the guide roller, and the chromium-free anti-oxidation solution is controlled during the soaking process. The temperature of the oxidizing solution is 28°C, the soaking time is 3s, and then it is squeezed dry by a squeeze roller, blown dry with a high-pressure air knife at room temperature, and then directly wound up, which is a semi-finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com