A kind of water-based PET heat-shrinkable film plastic printing ink and preparation method thereof

A heat-shrinkable film and plastic printing technology, applied in the field of plastic printing inks, can solve problems affecting workers' health, non-applicability of environmental regulations and policies, VOC emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

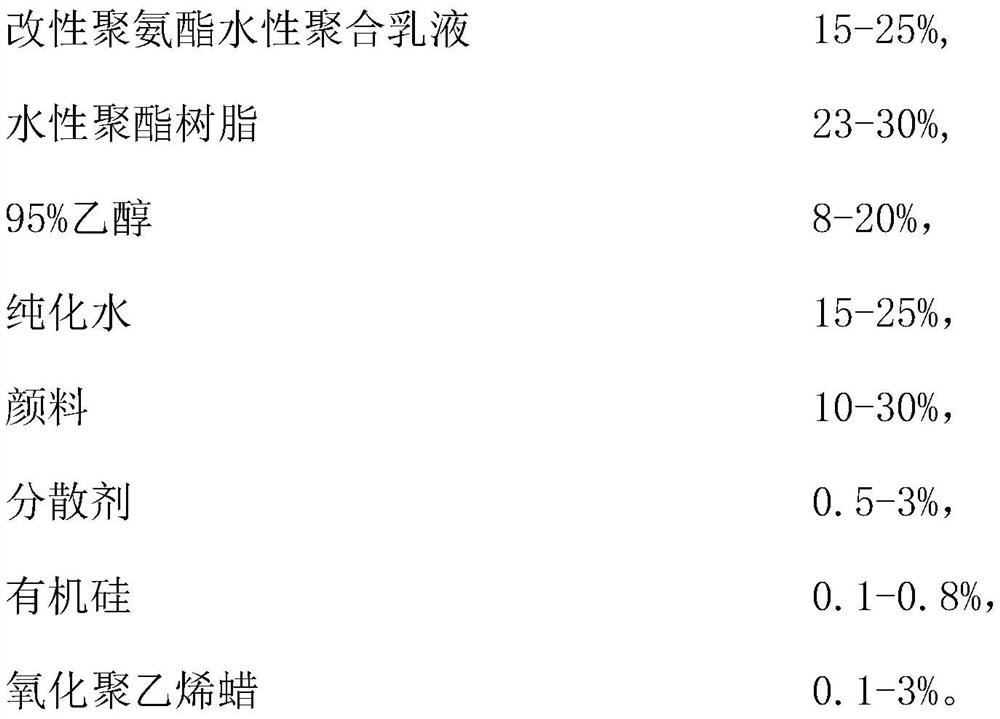

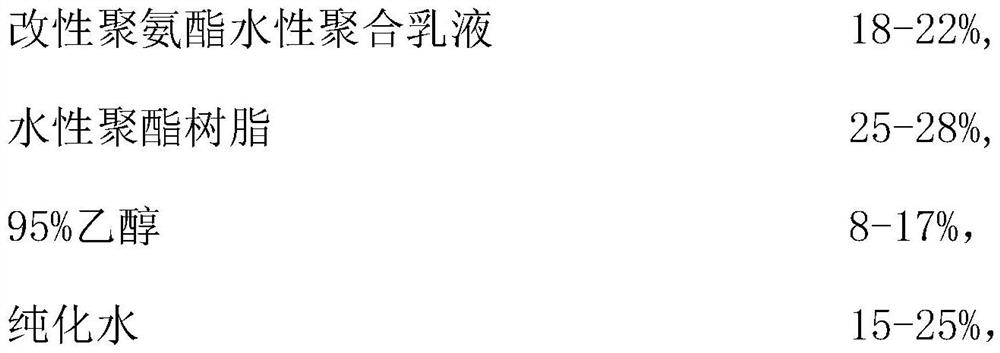

Method used

Image

Examples

Embodiment 1

[0027] A water-based PET heat-shrinkable film plastic printing ink, comprising the following components by weight percentage: modified polyurethane water-based polymer emulsion 18%, water-based polyester resin 25%, 95% ethanol 9.5%, purified water 15%, titanium dioxide 30%, dispersant 0.5%, silicone 0.5%, oxidized polyethylene wax 1.5%. This formula is white ink formula, and preparation method comprises the following steps:

[0028] (1) Step 1: Weigh the raw materials according to the weight percentage of the above formula, first put purified water and 95% ethanol into the mixing tank, set the mixer speed to 325r / min, stir for 3 minutes, then mix the dispersant and modified polyurethane water-based polymerization Put the emulsion into the mixing tank, and continue to stir for 18 minutes until the materials are mixed evenly to obtain a resin mixture;

[0029] (2) Step 2: put titanium dioxide, silicone and oxidized polyethylene wax into the resin mixture in the mixing tank, set...

Embodiment 2

[0033] A water-based PET heat-shrinkable film plastic printing ink, comprising the following components by weight percentage: modified polyurethane water-based polymer emulsion 20%, water-based polyester resin 28%, 95% ethanol 16.5%, purified water 22%, phthalocyanine Blue (15:3) 10%, dispersant 2%, silicone 0.3%, oxidized polyethylene wax 1.2%. This formula is blue ink formula, and preparation method comprises the following steps:

[0034] (1) Step 1: Weigh the raw materials according to the weight percentage of the above formula, first put purified water and 95% ethanol into the mixing tank, set the mixer speed to 300r / min, stir for 3 minutes, and then mix the dispersant and modified polyurethane water-based polymerization Put the emulsion into the mixing tank, and continue to stir for 20 minutes until the materials are mixed evenly to obtain a resin mixture;

[0035] (2) Step 2: Put phthalocyanine blue (15:3), silicone and oxidized polyethylene wax into the resin mixture i...

Embodiment 3

[0039] A water-based PET heat-shrinkable film plastic printing ink, including the following components by weight percentage: modified polyurethane water-based polymer emulsion 22%, water-based polyester resin 27.6%, 95% ethanol 10.6%, purified water 24%, P.R.254 Red 11.5%, dispersant 2.8%, silicone 0.3%, oxidized polyethylene wax 1.2%. This formula is red ink formula, and preparation method comprises the following steps:

[0040] (1) Step 1: Weigh the raw materials according to the weight percentage of the above formula, first put purified water and 95% ethanol into the mixing tank, set the mixer speed to 350r / min, stir for 3 minutes, and then mix the dispersant and modified polyurethane water-based polymerization Put the emulsion into the mixing tank, and continue to stir for 15 minutes until the materials are mixed evenly to obtain a resin mixture;

[0041] (2) Step 2: Put P.R.254 red, silicone and oxidized polyethylene wax into the resin mixture in the mixing tank, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com