High-temperature-resistant pressing-resistant anti-deformation rubber used for mining machinery buffering cushion

A technology of cushioning and high temperature resistance, applied in the field of rubber materials, can solve the problems of loss of cushioning and anti-collision effect of cushioning cushions, reducing the mechanical properties and rebound effect of cushioning cushion rubber, and reducing the resilience of rubber materials, etc., and achieving a small change in elastic limit. , Good resilience, stable tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

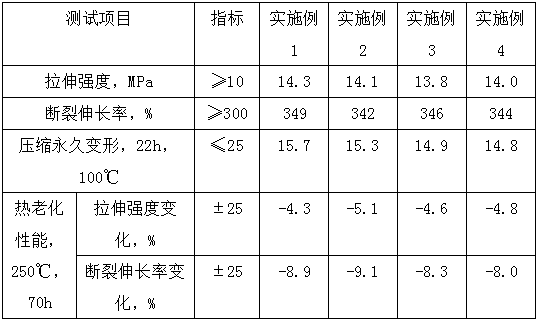

Embodiment 1

[0020] A kind of high temperature and pressure resistant anti-deformation rubber for mining machinery buffer pad, according to the mass parts, the rubber includes the following components: 100 parts of base rubber, 14 parts of silicone oil, 6 parts of butadiene, 4 parts of zinc powder, silicon dioxide powder 3 parts, 3 parts of alumina, 12 parts of white carbon black, 3 parts of magnesium oxide, 2 parts of stearic acid, 1 part of high temperature modifier, 0.5 parts of anti-aging agent, 10 parts of coupling agent, 3 parts of crosslinking agent, catalyst 1 serving.

[0021] Wherein, the base rubber includes butadiene rubber, nitrile rubber, neoprene and styrene-butadiene rubber, and the mass ratio of the four is 3:2:2:2. The high-temperature modifier uses nitrogen-phenylamide high-temperature-resistant modifier; silica powder is fumed silica after silane coupling agent is used for hydrophobic treatment; anti-aging agent RD is selected, and the coupling agent is silane coupling ...

Embodiment 2

[0025] A high temperature and pressure resistant anti-deformation rubber for a mine machinery buffer pad, the rubber includes the following components in parts by mass: 120 parts of base rubber, 16 parts of silicone oil, 9 parts of butadiene, 8 parts of zinc powder, and silicon dioxide powder 7 parts, 5 parts of alumina, 15 parts of white carbon black, 4 parts of magnesium oxide, 4 parts of stearic acid, 3.5 parts of high-temperature modifier, 2 parts of anti-aging agent, 14 parts of coupling agent, 4 parts of cross-linking agent, catalyst 3 copies.

[0026] Wherein, the base rubber includes butadiene rubber, nitrile rubber, neoprene and styrene-butadiene rubber, and the mass ratio of the four is 3:2:2:2. The high-temperature modifier is nitrogen-phenylamide high-temperature-resistant modifier; silica powder is fumed silica after silane coupling agent is used for hydrophobic treatment; anti-aging agent is anti-aging agent BLE, and the coupling agent is silane coupling agent. ...

Embodiment 3

[0030] A kind of high temperature and pressure resistant anti-deformation rubber for mining machinery buffer pad, the rubber includes the following components in parts by mass: 110 parts of base rubber, 15 parts of silicone oil, 7 parts of butadiene, 6 parts of zinc powder, and silicon dioxide powder 5 parts, 4 parts of alumina, 13 parts of white carbon black, 3.5 parts of magnesium oxide, 3 parts of stearic acid, 2 parts of high-temperature modifier, 1.2 parts of anti-aging agent, 12 parts of coupling agent, 3.5 parts of cross-linking agent, catalyst 2 servings.

[0031] Wherein, the base rubber includes butadiene rubber, nitrile rubber, neoprene and styrene-butadiene rubber, and the mass ratio of the four is 3:2:2:2. The high-temperature modifier uses nitrogen-phenylamide high-temperature-resistant modifier; silica powder is fumed silica after silane coupling agent is used for hydrophobic treatment; anti-aging agent RD is selected, and the coupling agent is silane coupling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com