Shaping method suitable for flexible glass drawing

A technology of flexible glass and glass ribbon, which is applied in glass molding, glass molding, glass manufacturing equipment, etc., can solve problems such as warping, uneven temperature field temperature, and low precision of mechanical assembly, so as to prevent warping and thickness poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Soda-lime-silica glass granules are selected for melting, and the specific composition of the glass is: by weight percentage, SiO 2 72%, Al 2 o 3 1.5%, CaO8%, MgO4%, Na 2 O14.5%. The molten glass flows out through a platinum slit with a width of 2mm.

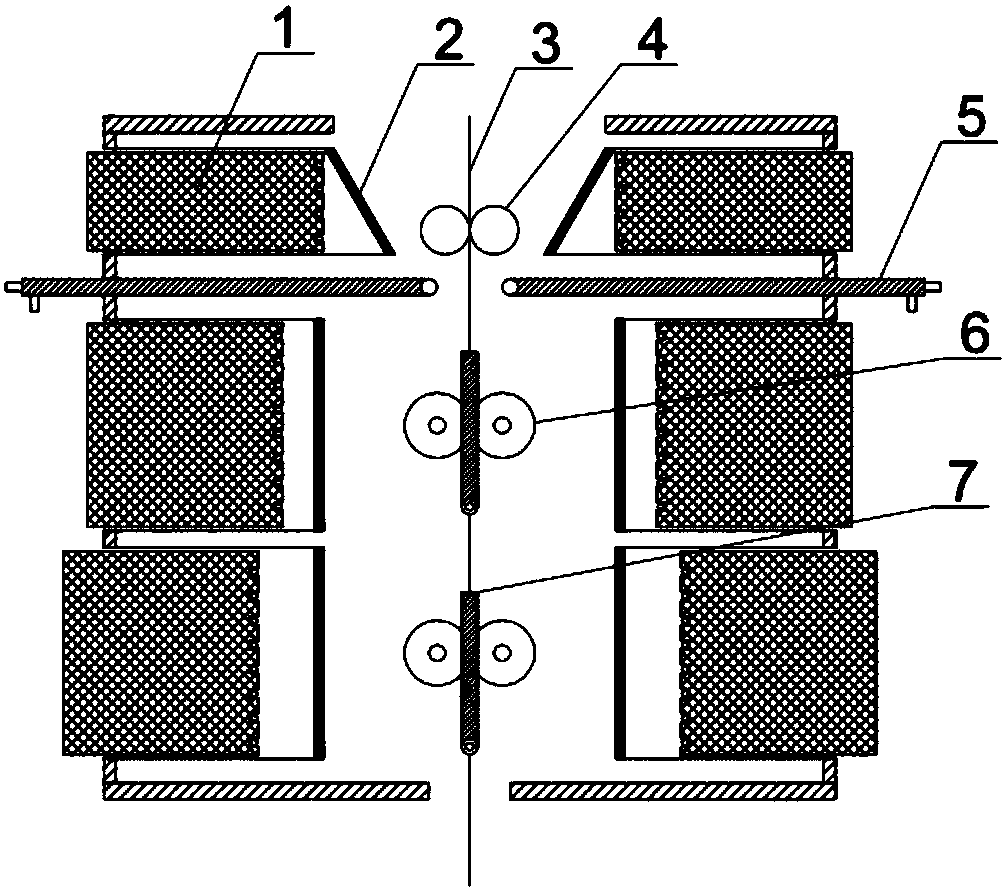

[0031] The heating modules in the shaping furnace are divided into 3 layers, 6 groups in total, and each group of heating modules is composed of 3 heating modules. 200×200mm. The front end of each group of heating modules is provided with a polycrystalline silicon carbide plate, the distance between the bottom edge of the first polycrystalline silicon carbide plate and the glass ribbon is 12mm, and the distance between the bottom edge of the second and third layer polycrystalline silicon carbide plates and the glass ribbon 20mm. By adjusting the position of the heating module away from the glass ribbon back and forth, the transverse temperature field is made uniform. Control the temperature at the center glass ribb...

Embodiment 2

[0039] Soda-lime-silica glass granules are selected for melting, and the specific composition of the glass is: by weight percentage, SiO 2 72%, Al 2 o 3 1.5%, CaO8%, MgO4%, Na 2 O14.5%. The molten glass flows out through a platinum slit with a width of 2mm.

[0040] The heating modules in the shaping furnace are divided into 3 layers, a total of 6 groups. Each group of heating modules is composed of 5 heating modules. 120×200mm. The front end of each group of heating modules is provided with a polycrystalline silicon carbide plate, the distance between the bottom edge of the first polycrystalline silicon carbide plate and the glass ribbon is 12mm, and the distance between the bottom edge of the second and third layer polycrystalline silicon carbide plates and the glass ribbon 20mm. By adjusting the position of the heating module away from the glass ribbon back and forth, the transverse temperature field is made uniform. The temperature at the center glass ribbon of the ...

Embodiment 3

[0048] Soda-lime-silica glass granules are selected for melting, and the specific composition of the glass is: by weight percentage, SiO 2 72%, Al 2 o 3 1.5%, CaO8%, MgO4%, Na 2 O14.5%. The molten glass flows out through a platinum slit with a width of 2mm.

[0049] The heating modules in the shaping furnace are divided into 3 layers, a total of 6 groups. Each group of heating modules is composed of 5 heating modules. 120×200mm. The front end of each group of heating modules is provided with a polycrystalline silicon carbide plate, the distance between the bottom edge of the first polycrystalline silicon carbide plate and the glass ribbon is 12mm, and the distance between the bottom edge of the second and third layer polycrystalline silicon carbide plates and the glass ribbon 20mm. By adjusting the position of the heating module away from the glass ribbon back and forth, the transverse temperature field is made uniform. The temperature at the center glass ribbon of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com