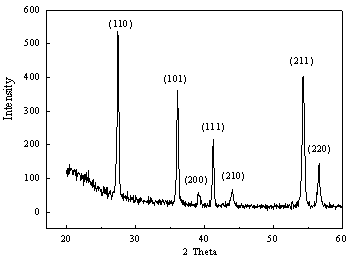

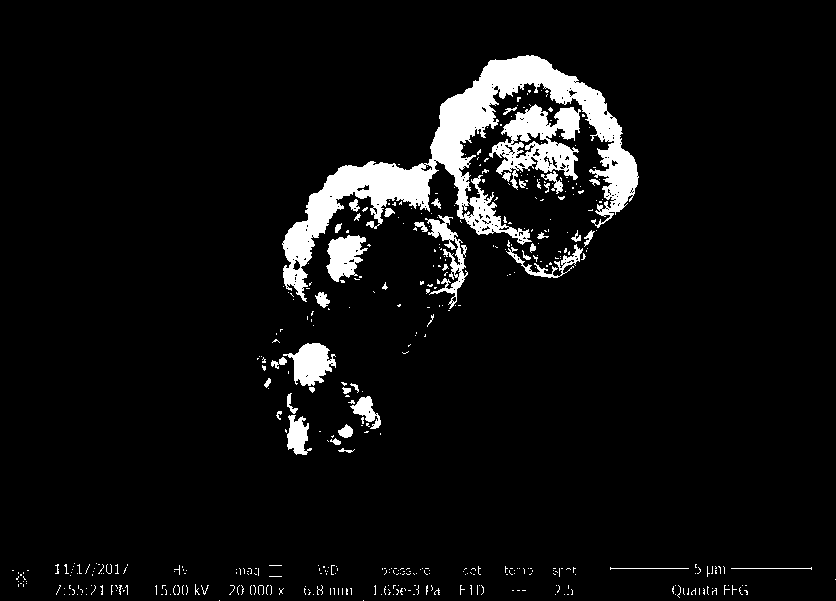

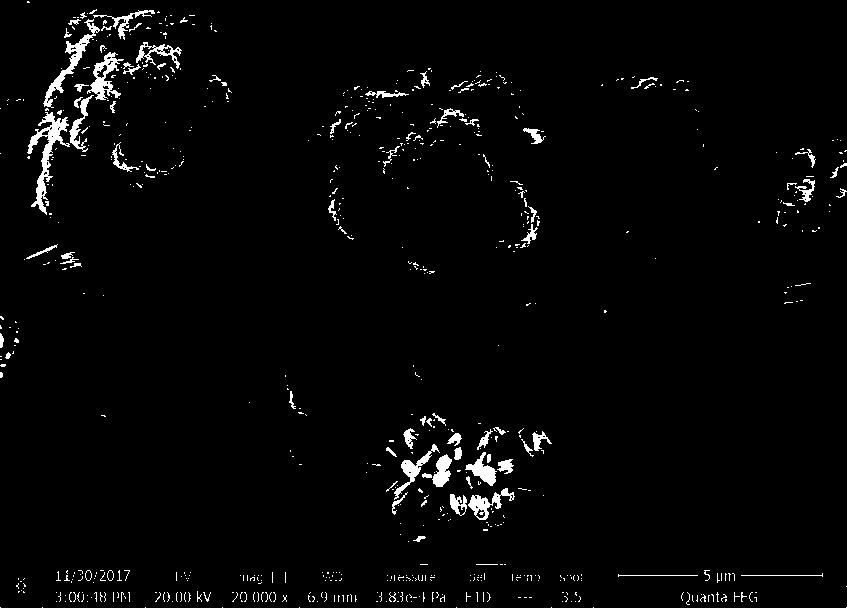

A kind of preparation method of micron flower structure rutile phase titanium dioxide

A rutile phase, titanium dioxide technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide and other directions, can solve the problems of low specific surface area of particles, unfavorable photocatalytic reaction, complex process, etc., and achieve high specific surface area, catalytic Good effect, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: a kind of preparation method of micron flower structure rutile phase titanium dioxide, comprises the following steps:

[0018] (1) Weigh 0.2 g of spherical titanium powder and place it in a beaker, add 19 ml of deionized water, and stir at a constant speed to make it evenly mixed;

[0019] (2) Measure 10 ml of 36-38 wt% hydrochloric acid and 1 ml of hydrogen peroxide, pour it into the beaker in step (1), and place it on a magnetic stirrer to stir slowly for 30 min;

[0020] (3) Transfer the above solution to a 50 ml hydrothermal synthesis kettle, tighten the reaction kettle, and place it in a constant temperature blast drying oven at 200 °C for hydrothermal reaction for 18 h;

[0021] (4) Separating the hydrothermal reaction product from solid to liquid to obtain a solid powder, washing the powder repeatedly with deionized water until neutral, drying at 80°C, and grinding to obtain the product.

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of micron flower structure rutile phase titanium dioxide, comprises the following steps:

[0023] (1) Weigh 0.2 g of spherical titanium powder and place it in a beaker, add 18 ml of deionized water, stir at a constant speed to make it evenly mixed;

[0024] (2) Measure 10 ml of 36-38 wt% hydrochloric acid and 2 ml of hydrogen peroxide, pour it into the beaker in step (1), and place it on a magnetic stirrer to stir slowly for 30 min;

[0025] (3) Transfer the above solution to a 50 ml hydrothermal synthesis kettle, tighten the reaction kettle, and place it in a constant temperature blast drying oven at 200 °C for hydrothermal reaction for 10 h;

[0026] (4) Separating the hydrothermal reaction product from solid to liquid to obtain a solid powder, washing the powder repeatedly with deionized water until neutral, drying at 80°C, and grinding to obtain the product.

Embodiment 3

[0027] Embodiment 3: a kind of preparation method of micron flower structure rutile phase titanium dioxide, comprises the following steps:

[0028] (1) Weigh 0.2 g of spherical titanium powder and place it in a beaker, add 19 ml of deionized water, and stir at a constant speed to make it evenly mixed;

[0029] (2) Measure 10 ml of 36-38 wt% hydrochloric acid and 1 ml of hydrogen peroxide, pour it into the beaker in step (1), and place it on a magnetic stirrer to stir slowly for 40 min;

[0030] (3) Transfer the above solution to a 50 ml hydrothermal synthesis kettle, tighten the reaction kettle, and place it in a constant temperature blast drying oven at 200 °C for hydrothermal reaction for 14 h;

[0031] (4) Separating the hydrothermal reaction product from solid to liquid to obtain a solid powder, washing the powder repeatedly with deionized water until neutral, drying at 80°C, and grinding to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com