Micro-nano blocking lubricant for drilling fluid and preparation method thereof

A micro-nano, drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of drilling fluid lubricity decrease, large, only increase, and low application value, so as to improve lubricity and avoid Mutual interference, effect of improving mud cake quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

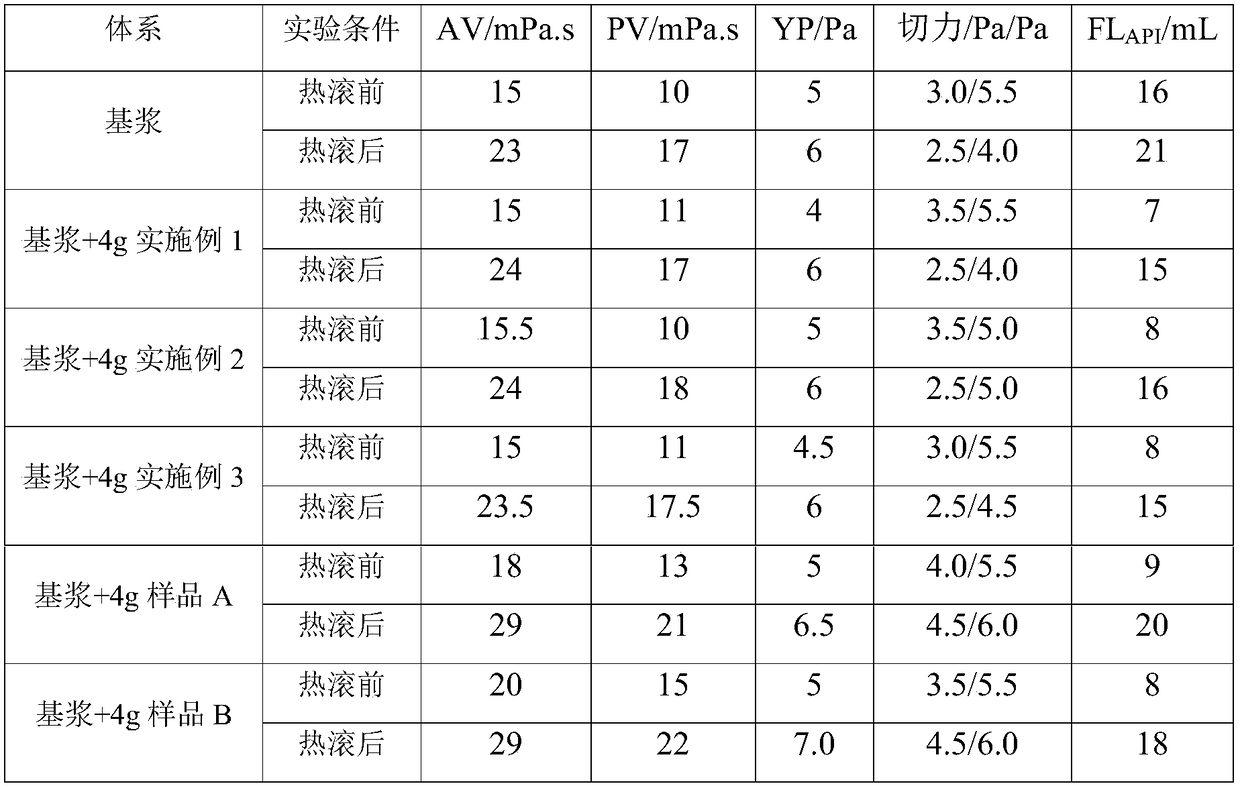

Examples

Embodiment 1

[0046] A method for preparing a micro-nano plugging lubricant for drilling fluid, comprising the following steps:

[0047] (1) Weigh 30 parts by weight of paraffin and 50 parts by weight of white oil into a three-necked flask, stir at a speed of 300 rpm, heat up to 75°C, add 30 parts by weight of a compound emulsifier after melting, and stir for 30 minutes; slowly add 40 parts by weight of 75°C Add 1.0 parts by weight of emulsifying aid to hot water, and continue stirring at 300 rpm for 30 minutes; add 60 parts by weight of hot water at 75°C, stir for 20 minutes, and cool down to 40°C to obtain a nanoemulsion.

[0048] Among them, the emulsifying aid is 1.0mol / L hydrochloric acid solution, and the compound emulsifier is composed of Span 80 and Tween 80 in a weight ratio of 1:1.

[0049] (2) Weigh graphite fine powders of 325 mesh, 800 mesh, 1200 mesh, 2000 mesh and 4000 mesh and mix them evenly according to the weight ratio of 1:1:1:1:1 to obtain composite graphite fine powder...

Embodiment 2

[0052] A method for preparing a micro-nano plugging lubricant for drilling fluid, comprising the following steps:

[0053] (1) Weigh 40 parts by weight of paraffin and 40 parts by weight of white oil into a three-necked flask, stir at a speed of 400 rpm, heat up to 80°C, add 25 parts by weight of a compound emulsifier after melting, and stir for 30 minutes; slowly add 50 parts by weight of 80°C Add 0.75 parts by weight of emulsifying aid to hot water, and continue to stir at 400 rpm for 30 minutes; (3) Add 50 parts by weight of hot water at 80°C, stir for 20 minutes, and cool down to 45°C to obtain a nanoemulsion.

[0054] Among them, the emulsifying aid is 2.0mol / L acetic acid solution, and the compound emulsifier is composed of Span 80 and Tween 80 according to the weight ratio of 1:1.25.

[0055] (2) Weigh graphite fine powders of 325 mesh, 800 mesh, 1200 mesh, 2000 mesh and 4000 mesh and mix them evenly according to the weight ratio of 1:1:1:1:1 to obtain composite graphit...

Embodiment 3

[0058] A method for preparing a micro-nano plugging lubricant for drilling fluid, comprising the following steps:

[0059] (1) Weigh 50 parts by weight of paraffin and 30 parts by weight of white oil into a three-necked flask, stir at a speed of 500 rpm, heat up to 85°C, add 20 parts by weight of a compound emulsifier after melting, and stir for 30 minutes; slowly add 60 parts by weight of 85°C Add 0.5 parts by weight of emulsifying aid to hot water, and continue stirring at 500 rpm for 30 minutes; (3) Add 40 parts by weight of hot water at 85° C., stir for 20 minutes, and cool down to 50° C. to obtain a nanoemulsion.

[0060] Among them, the emulsifying aid is 1.5mol / L sulfuric acid solution, and the compound emulsifier is made of Span 80 and Tween 80 according to the weight ratio of 1:1.5.

[0061] (2) Weigh graphite fine powders of 325 mesh, 800 mesh, 1200 mesh, 2000 mesh and 4000 mesh and mix them evenly according to the weight ratio of 1:1:1:1:1 to obtain composite graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com