Power generation method by using waste heat of aluminum electrolysis gas

A flue gas waste heat, aluminum electrolysis technology, applied in electrical components, generators/motors, etc., can solve the problems of increasing flue gas processing capacity and fan energy consumption, affecting the operating cost and purification efficiency of the purification system, and reducing flue gas. The processing capacity and the number of fans, the energy saving effect is obvious, and the system structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the embodiments of the present invention with reference to the drawings.

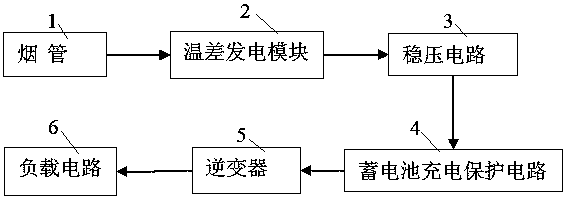

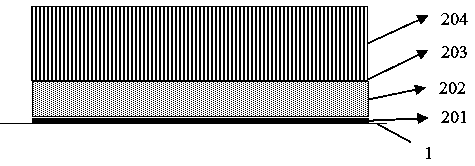

[0022] The hot end surface 202 of the semiconductor power generating sheet of the semiconductor temperature difference module is tightly attached to the heat conduction film 201 of the smoke pipe; the heat conduction film 201 is tightly attached to the outer surface of the tobacco pipe 1; the cold end surface of the semiconductor power generation sheet of the semiconductor temperature difference module 203 is connected to the fin radiator 204 to dissipate heat by air convection; the semiconductor thermoelectric modules 2 are grouped according to the side of the smoke pipe, and the semiconductor thermoelectric power generation sheets in the group are connected in parallel, series or array mode, and then connected to the stabilizer Circuit 3.

[0023] The storage battery 401 is connected with an inverter 5 to convert direct current to alternating current and connect to the load c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com