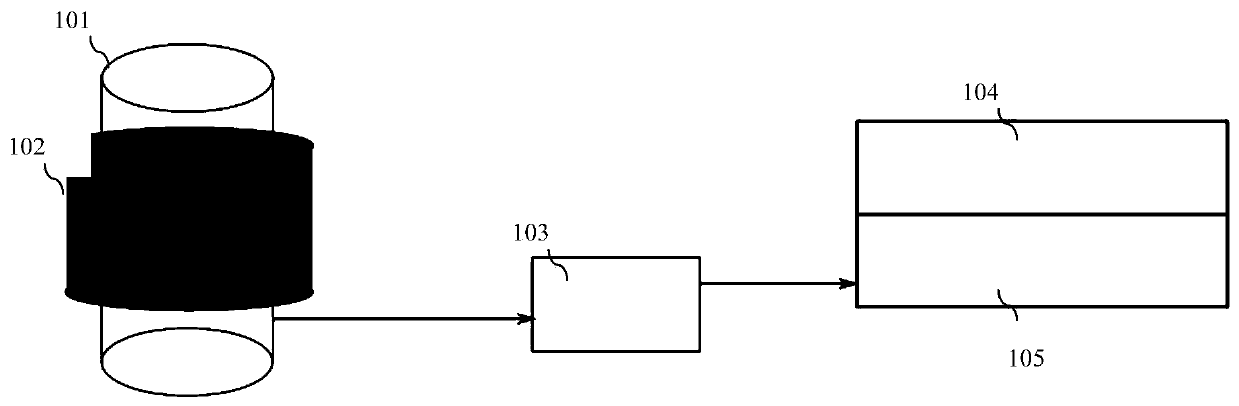

A fuel reforming reactor

A technology for reforming reactors and fuels, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of inconvenient storage and transportation, limited promotion in the field of portable power sources, etc., to reduce heat, improve reforming efficiency, The effect of changing the intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

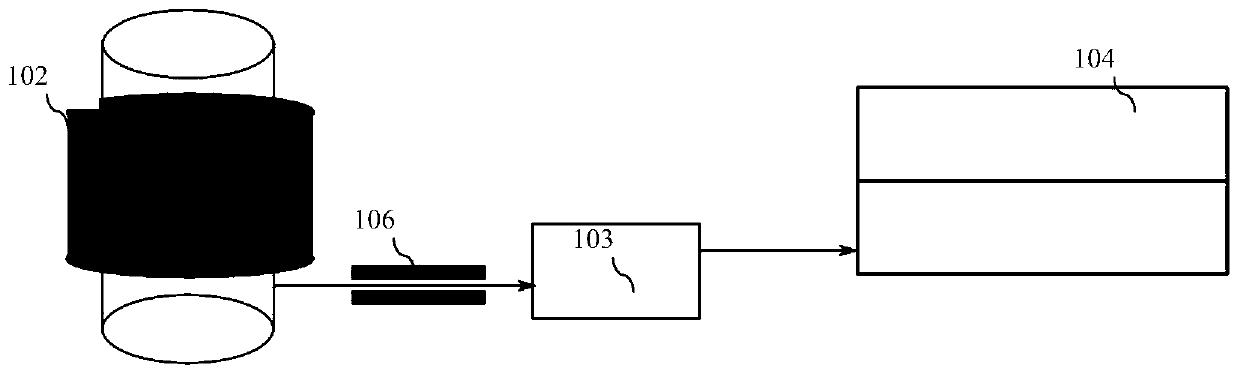

[0028] The reformer is carved and milled from aluminum alloy 6082. The reforming catalyst uses CuAlZn methanol reforming catalyst with an average particle size of 1.5mm, and the combustion catalyst uses Pt / Al with an average particle size of 1mm. 2 o 3 The catalyst and the fuel tank are covered with NdFeB magnet blocks, and the size of the magnet blocks is 50mm*10mm*2mm.

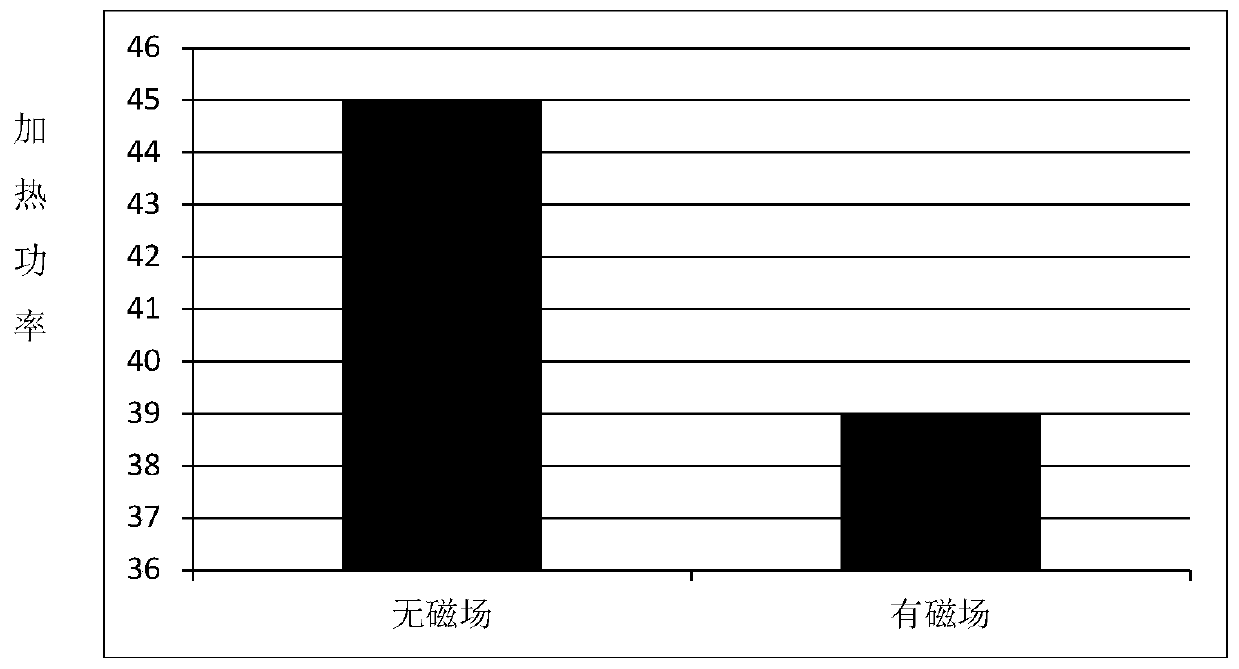

[0029] There is an electric heating sheet attached around the vaporization chamber. When starting up, first heat the vaporization chamber to 110°C, then feed 2mL / min of methanol, adjust the electric heating power, and maintain the temperature of the vaporization chamber at 110°C. image 3 .

Embodiment 2

[0033] The fuel processor is made of aluminum alloy 6082. The combustion chamber and the reforming chamber are closely connected, and the length and width of the two are the same. The vaporization chamber is a separate component. The flow channel in the reforming chamber is in the form of a single serpentine, with a channel width of 8 mm, filled with CuAlZn methanol reforming catalyst with an average particle size of 1.5 mm. The combustion chamber is a parallel groove type, which is filled with 0.5% Pt / Al2O3 combustion catalyst in the form of 0.6-1mm particles. The fuel tank and the pipeline entering the vaporization chamber are covered with NdFeB magnet blocks.

[0034] Before the operation of the reformer, the reforming catalyst is first reduced, the condition is 250° C., the reduction gas is a mixture of 5% H2 and N2, and the time is 2 hours. During operation, first heat the combustion chamber to 120°C with a heating rod, and then feed 1mL / min methanol aqueous solution (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com