Process for extracting secondary salt from desulfurization waste liquid

A desulfurization waste liquid, process technology, applied in the direction of ammonium sulfate, thiosulfate/dithionite/polythionite, thiocyanate, etc., can solve the harsh environment of production site, reduce desulfurization effect, Increase operating costs and other issues, achieve great economic and environmental benefits, avoid secondary pollution, and improve the effect of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

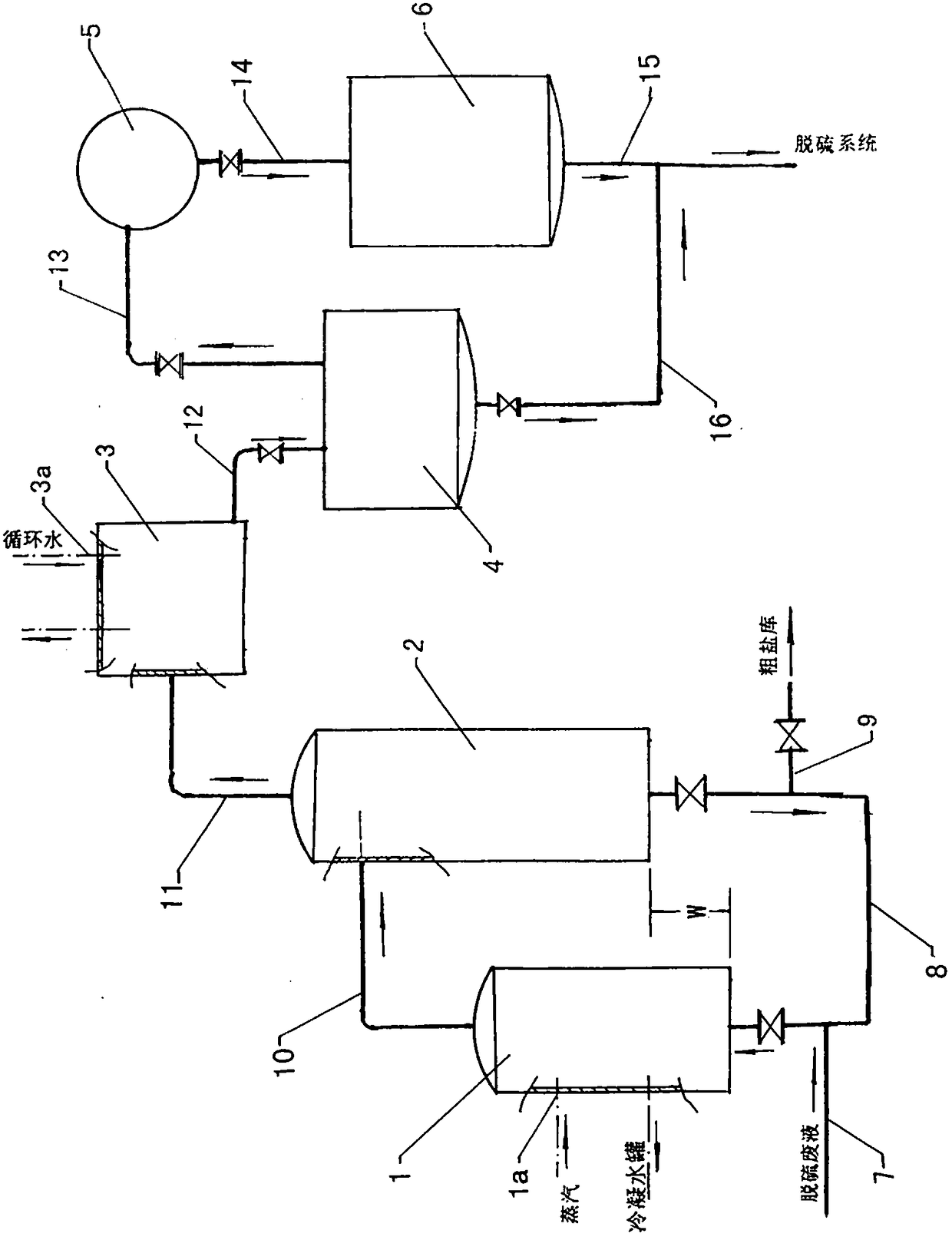

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the devices required to realize the process of extracting secondary salt from desulfurization waste liquid include evaporator 1, evaporation chamber 2, condensation cooler 3, ammonia water tank 4, vacuum pump 5 and ammonia water recovery tank 6, which are all prior art. Products can be bought in the market, or they can be designed and manufactured according to the needs of the site, and non-standard products. In addition, it also includes desulfurization waste liquid input pipe 7, concentrated liquid delivery pipe 8, condensate output pipe 9, gas-liquid mixture delivery pipe 10, ammonia steam delivery pipe 11, ammonia water input pipe 12, uncondensed ammonia gas delivery pipe 13. The first ammonia gas delivery pipe 14, the second ammonia gas delivery pipe 15 and the ammonia water output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com