Taste-masking composition and use thereof

A technology of composition and application, which is applied in the fields of pharmaceuticals, health care products, and food science, and can solve problems such as poor water solubility and bad odor, achieve the effects of shielding oily smell, improving oral compliance, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

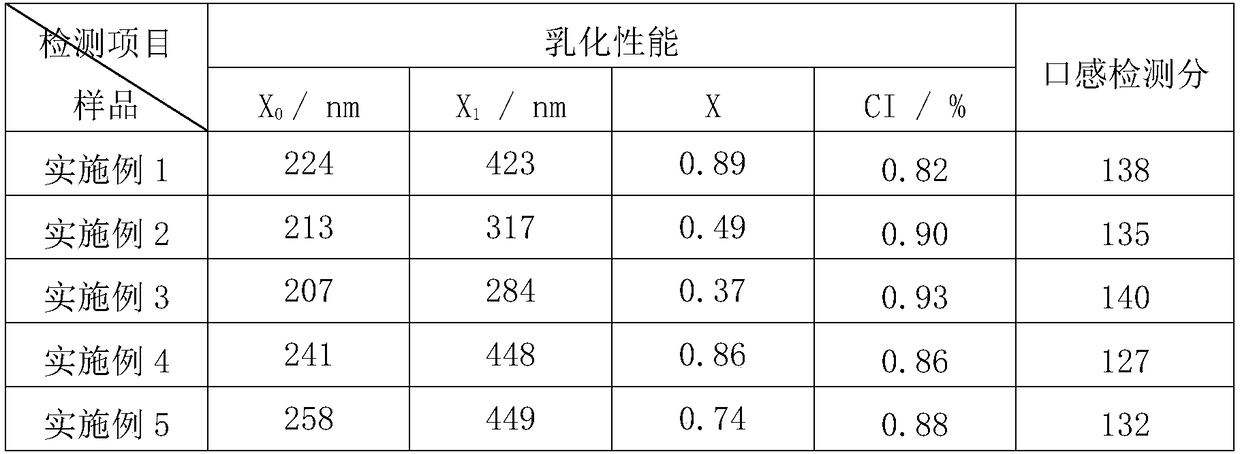

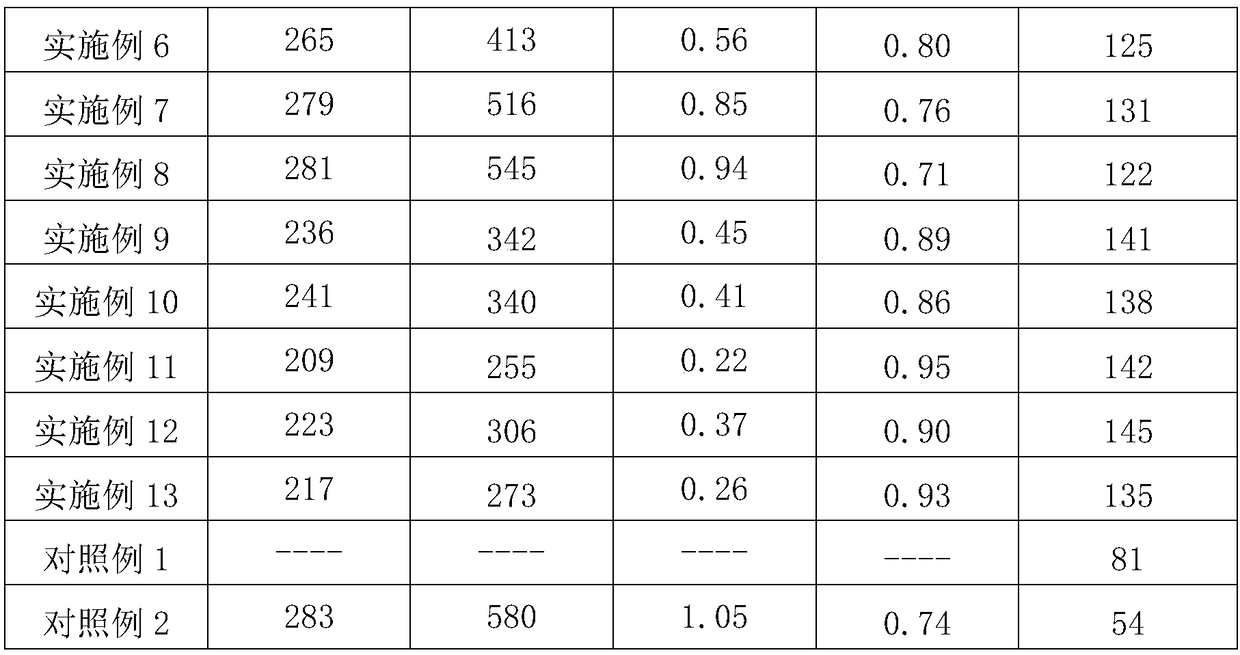

Examples

Embodiment 1

[0049] 1. Formula:

[0050] 30g linseed oil, 30g orange peel oil, 1g sucralose, 10g lauryl sorbitan, 20g polyoxyethylene lauryl ether, 1000g double distilled water

[0051] 2. Process:

[0052] Stir and mix linseed oil, orange peel oil, and lauryl sorbitan evenly to prepare an oil phase; mix sucralose and polyoxyethylene lauryl ether evenly, then slowly add to double distilled water at 40°C, and stir while adding , until the sucralose and polyoxyethylene lauryl ether are completely dissolved in double distilled water to prepare the water phase; at 25°C, when the stirring speed is 100rpm, slowly add the oil phase to the water phase and mix, and at the same time use high-pressure homogenization The quality emulsification method is used to prepare the mixed solution into a nanoemulsion; the nanoemulsion is filtered and sterilized through a 0.25 μm sterile filter membrane to obtain a nanoemulsion product with a good taste.

Embodiment 2

[0054] 1. Formula:

[0055] 80g fish oil, 50g ginger oil, 5g malic acid, 5g aspartame, 100g soybean lecithin, 200g vitamin C, 5000g twice distilled water,

[0056] 2. Process:

[0057] Stir and mix fish oil, ginger oil, and soybean lecithin evenly to prepare an oil phase; mix evenly malic acid, aspartame, and vitamin C, and slowly add to double distilled water at 40°C, stirring while adding until the malic acid , aspartame, and vitamin C were completely dissolved in twice-distilled water to prepare a water phase; at 25°C, when the stirring speed was 500rpm, the oil phase was slowly added dropwise to the water phase for mixing, and at the same time, ultrasonic emulsification was used to mix the The mixed liquid is prepared into a nanoemulsion; the nanoemulsion is filtered and sterilized through a 0.25 μm sterile filter membrane to obtain a nanoemulsion product with good taste.

Embodiment 3

[0059] 1. Formula:

[0060] 50g fish oil, 50g orange peel oil, 9g stevioside, 10g egg yolk lecithin, 50g polysorbate 60, 10g lutein, 1000g double distilled water

[0061] 2. Process:

[0062] Stir and mix fish oil, orange peel oil, egg yolk lecithin, and lutein evenly to prepare an oil phase; mix polysorbate 60 and stevioside evenly, and then slowly add to double distilled water at 40°C, stirring while adding, Until the polysorbate 60 and stevioside are completely dissolved in double-distilled water, the water phase is prepared; at 25°C, when the stirring speed is 500rpm, the oil phase is slowly added dropwise to the water phase for mixing, and a high-shear emulsification method is used at the same time , preparing the mixed solution into a nanoemulsion; filtering and sterilizing the nanoemulsion through a 0.25 μm sterile filter membrane to obtain a nanoemulsion product with good taste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com